Model SB1016/SB1036 | O P E R A T I O N | For Machines Mfg. Since 7/09 |

Mounting Center in Tailstock

Either the

To mount a center in the tailstock:

1.DISCONNECT LATHE FROM POWER!

2.Thoroughly clean and dry the tapered mating surfaces of the tailstock quill bore and the

3.Use the tailstock quill handwheel to feed the quill out from the casting about 1". (Do not feed the quill out of the casting more than 2" or stability and accuracy will be reduced.)

4.Insert the center into the tailstock quill.

5.Seat the center firmly into the quill during workpiece installation by rotating the quill handwheel clockwise to apply pressure, with the center engaged in the center hole in the workpiece.

Note: Only apply enough pressure with the tailstock quill to securely mount the workpiece between centers. Avoid over- tightening the center against the workpiece, or it may become difficult to remove later, and it will result in excessive friction and heat, which may damage the workpiece and the center.

Removing Center from Tailstock

To remove the center from the quill, hold onto it with a rag in one hand, then rotate the tailstock handwheel counterclockwise to draw the quill back into the casting until the center releases. If the center does not come out, extend the quill, and use a drift key (see Figure 62) to drive the center out.

Steady Rest

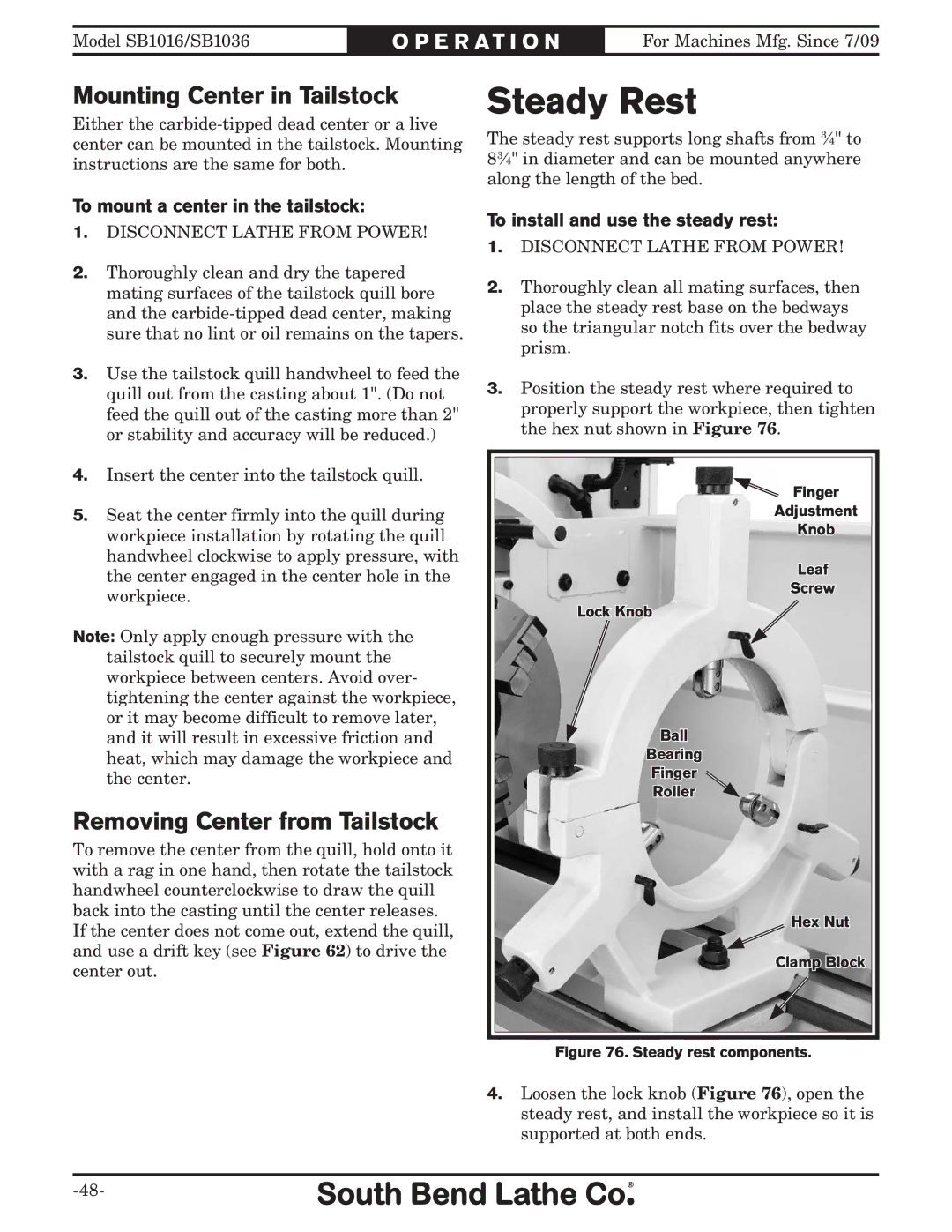

The steady rest supports long shafts from 3⁄4" to 83⁄4" in diameter and can be mounted anywhere along the length of the bed.

To install and use the steady rest:

1.DISCONNECT LATHE FROM POWER!

2.Thoroughly clean all mating surfaces, then place the steady rest base on the bedways so the triangular notch fits over the bedway prism.

3.Position the steady rest where required to properly support the workpiece, then tighten the hex nut shown in Figure 76.

Finger

Adjustment

Knob

Leaf

Screw

Lock Knob

Ball

Bearing

Finger

Roller

Hex Nut

Clamp Block

Figure 76. Steady rest components.

4.Loosen the lock knob (Figure 76), open the steady rest, and install the workpiece so it is supported at both ends.