Model SB1016/SB1036 | P R E P A R A T I O N | For Machines Mfg. Since 7/09 |

Leveling & Mounting

You must level your machine and either use the included foot pads and leveling hardware or bolt your lathe to the floor. Because mounting your lathe to the floor with permanent hardware is an optional step and floor materials may vary, floor mounting hardware is not included.

Leveling

For accurate turning results and to prevent warping the cast iron bed and ways, the lathe bedways MUST be leveled from

Leveling machinery helps precision components, such as bedways, remain straight and flat during the lifespan of the machine. Components on an un leveled machine may slowly twist due to the dynamic loads placed on the machine during operation.

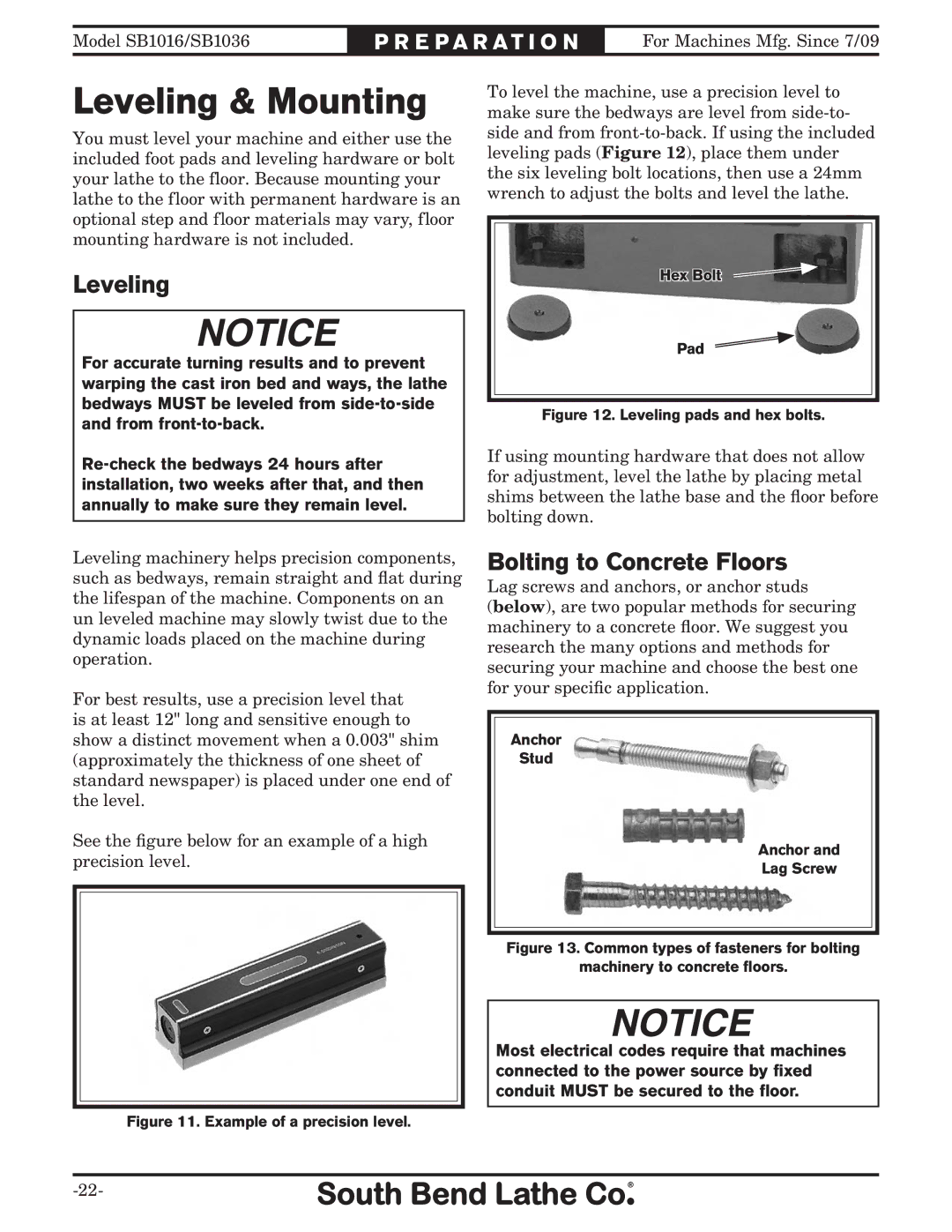

For best results, use a precision level that is at least 12" long and sensitive enough to show a distinct movement when a 0.003" shim (approximately the thickness of one sheet of standard newspaper) is placed under one end of the level.

See the figure below for an example of a high precision level.

To level the machine, use a precision level to make sure the bedways are level from

Hex Bolt

Pad

Figure 12. Leveling pads and hex bolts.

If using mounting hardware that does not allow for adjustment, level the lathe by placing metal shims between the lathe base and the floor before bolting down.

Bolting to Concrete Floors

Lag screws and anchors, or anchor studs

(below), are two popular methods for securing machinery to a concrete floor. We suggest you research the many options and methods for securing your machine and choose the best one for your specific application.

Anchor

Stud

LagAnchorScrewand anLadgAnchorScrew