For Machines Mfg. Since 7/09 | W A R R A N T Y | Model SB1016/SB1036 |

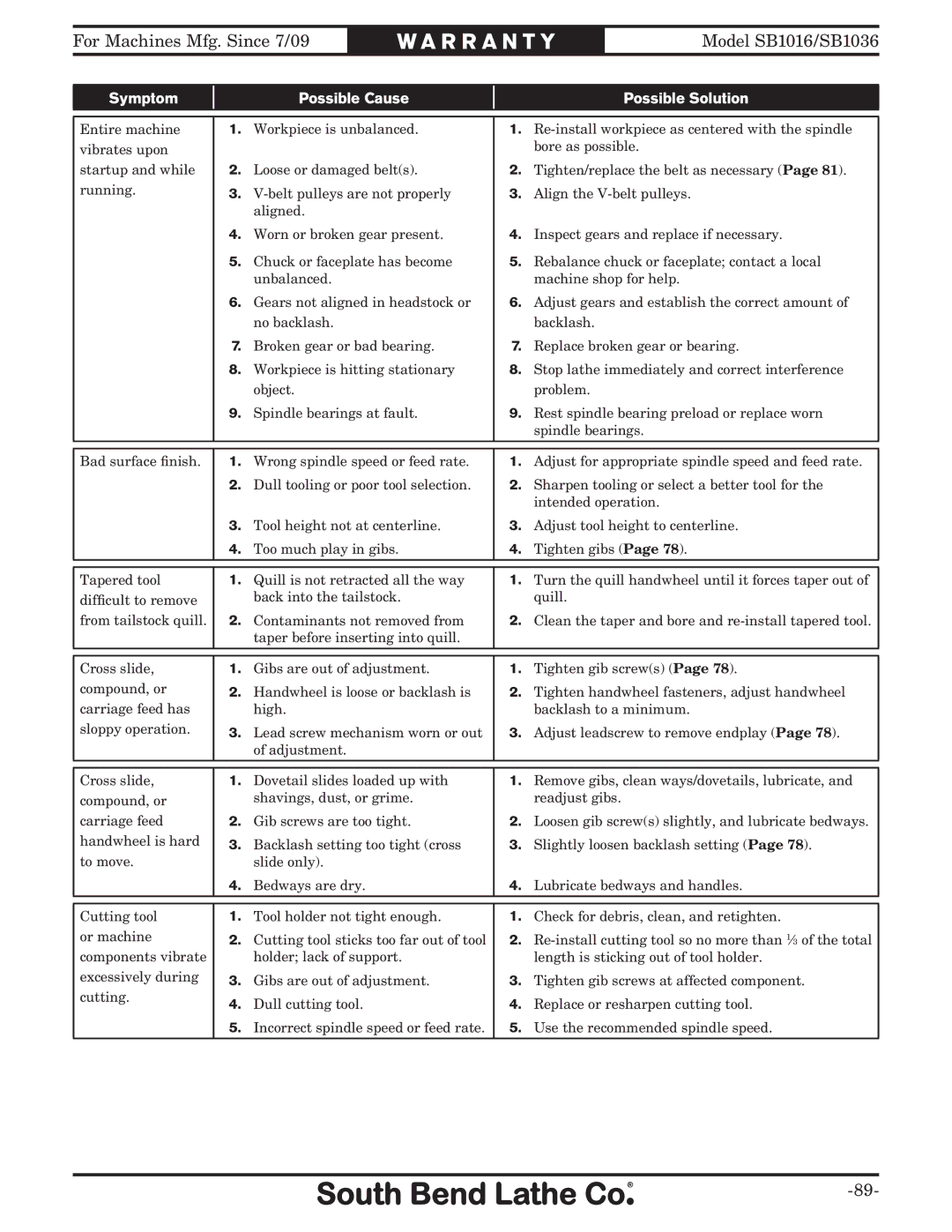

Symptom

Possible Cause

Possible Solution

Entire machine | 1. | Workpiece is unbalanced. | 1. | |

vibrates upon |

|

|

| bore as possible. |

startup and while | 2. | Loose or damaged belt(s). | 2. | Tighten/replace the belt as necessary (Page 81). |

running. | 3. | 3. | Align the | |

|

| aligned. |

|

|

| 4. | Worn or broken gear present. | 4. | Inspect gears and replace if necessary. |

| 5. | Chuck or faceplate has become | 5. | Rebalance chuck or faceplate; contact a local |

|

| unbalanced. |

| machine shop for help. |

6.Gears not aligned in headstock or 6. Adjust gears and establish the correct amount of

| no backlash. |

| backlash. |

7. | Broken gear or bad bearing. | 7. | Replace broken gear or bearing. |

8. | Workpiece is hitting stationary | 8. | Stop lathe immediately and correct interference |

| object. |

| problem. |

9.Spindle bearings at fault.9. Rest spindle bearing preload or replace worn spindle bearings.

Bad surface finish. | 1. | Wrong spindle speed or feed rate. | 1. | Adjust for appropriate spindle speed and feed rate. |

| 2. | Dull tooling or poor tool selection. | 2. | Sharpen tooling or select a better tool for the |

|

|

|

| intended operation. |

| 3. | Tool height not at centerline. | 3. | Adjust tool height to centerline. |

| 4. | Too much play in gibs. | 4. | Tighten gibs (Page 78). |

|

|

|

|

|

Tapered tool | 1. | Quill is not retracted all the way | 1. | Turn the quill handwheel until it forces taper out of |

difficult to remove |

| back into the tailstock. |

| quill. |

from tailstock quill. | 2. | Contaminants not removed from | 2. | Clean the taper and bore and |

|

| taper before inserting into quill. |

|

|

|

|

|

|

|

|

|

|

|

|

Cross slide, | 1. | Gibs are out of adjustment. | 1. | Tighten gib screw(s) (Page 78). |

compound, or | 2. | Handwheel is loose or backlash is | 2. | Tighten handwheel fasteners, adjust handwheel |

carriage feed has |

| high. |

| backlash to a minimum. |

sloppy operation. | 3. | Lead screw mechanism worn or out | 3. | Adjust leadscrew to remove endplay (Page 78). |

|

| of adjustment. |

|

|

|

|

|

|

|

Cross slide, | 1. | Dovetail slides loaded up with | 1. | Remove gibs, clean ways/dovetails, lubricate, and |

compound, or |

| shavings, dust, or grime. |

| readjust gibs. |

carriage feed | 2. | Gib screws are too tight. | 2. | Loosen gib screw(s) slightly, and lubricate bedways. |

handwheel is hard | 3. | Backlash setting too tight (cross | 3. | Slightly loosen backlash setting (Page 78). |

to move. |

| slide only). |

|

|

| 4. | Bedways are dry. | 4. | Lubricate bedways and handles. |

|

|

|

|

|

|

|

|

|

|

Cutting tool | 1. | Tool holder not tight enough. | 1. | Check for debris, clean, and retighten. |

or machine | 2. | Cutting tool sticks too far out of tool | 2. | |

components vibrate |

| holder; lack of support. |

| length is sticking out of tool holder. |

excessively during | 3. | Gibs are out of adjustment. | 3. | Tighten gib screws at affected component. |

cutting. | 4. | Dull cutting tool. | 4. | Replace or resharpen cutting tool. |

| ||||

| 5. | Incorrect spindle speed or feed rate. | 5. | Use the recommended spindle speed. |