For Machines Mfg. Since 7/09 | O P E R A T I O N | Model SB1016/SB1036 |

Centers

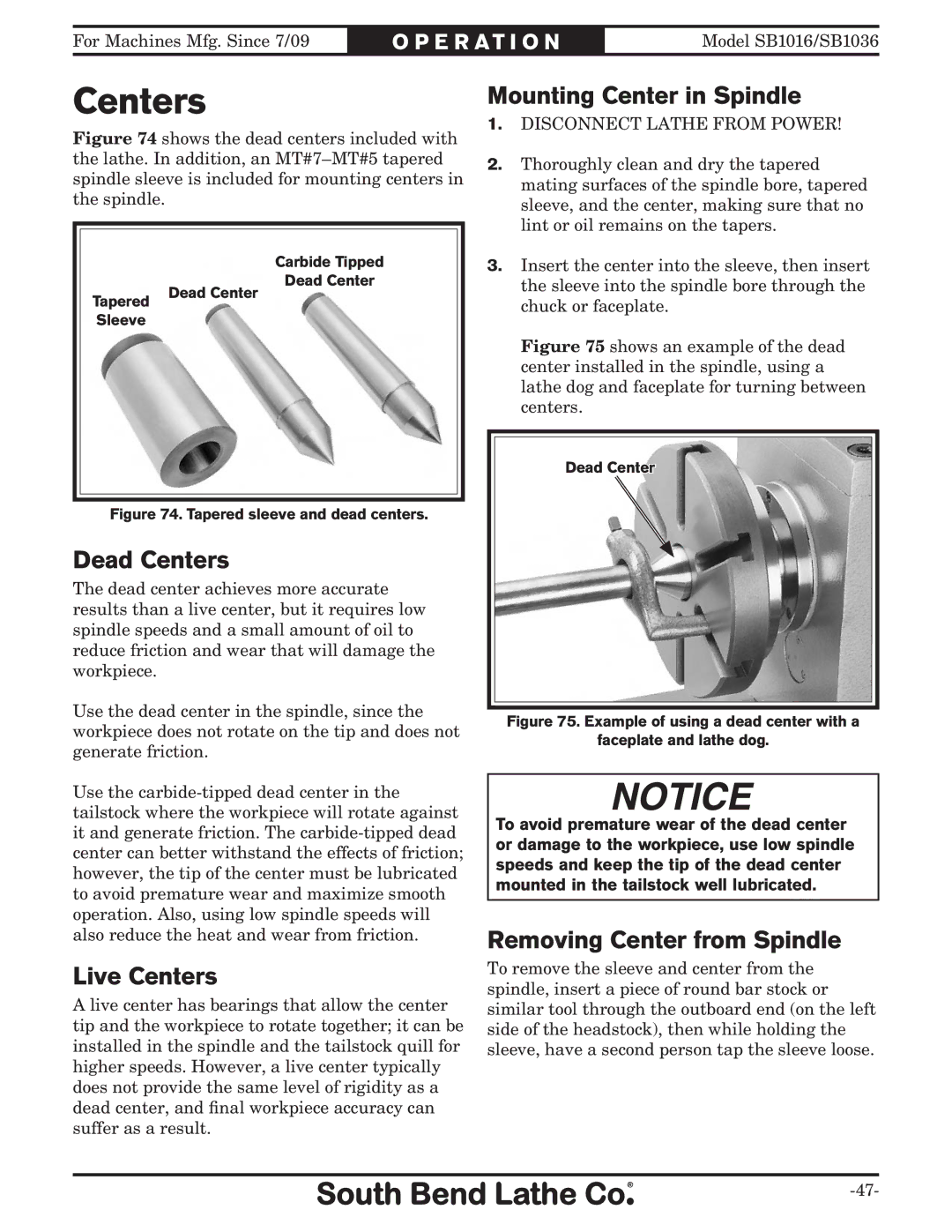

Figure 74 shows the dead centers included with the lathe. In addition, an MT#7–MT#5 tapered spindle sleeve is included for mounting centers in the spindle.

Mounting Center in Spindle

1. | DISCONNECT LATHE FROM POWER! |

2. | Thoroughly clean and dry the tapered |

| mating surfaces of the spindle bore, tapered |

| sleeve, and the center, making sure that no |

| lint or oil remains on the tapers. |

Tapered

Sleeve

Carbide Tipped

Dead Center

Dead Center

3. Insert the center into the sleeve, then insert |

the sleeve into the spindle bore through the |

chuck or faceplate. |

Figure 75 shows an example of the dead |

center installed in the spindle, using a |

lathe dog and faceplate for turning between |

centers. |

Dead Center

Figure 74. Tapered sleeve and dead centers.

Dead Centers

The dead center achieves more accurate results than a live center, but it requires low spindle speeds and a small amount of oil to reduce friction and wear that will damage the workpiece.

Use the dead center in the spindle, since the workpiece does not rotate on the tip and does not generate friction.

Use the

Live Centers

A live center has bearings that allow the center tip and the workpiece to rotate together; it can be installed in the spindle and the tailstock quill for higher speeds. However, a live center typically does not provide the same level of rigidity as a dead center, and final workpiece accuracy can suffer as a result.

Figure 75. Example of using a dead center with a

faceplate and lathe dog.

To avoid premature wear of the dead center or damage to the workpiece, use low spindle speeds and keep the tip of the dead center mounted in the tailstock well lubricated.

Removing Center from Spindle

To remove the sleeve and center from the spindle, insert a piece of round bar stock or similar tool through the outboard end (on the left side of the headstock), then while holding the sleeve, have a second person tap the sleeve loose.