For Machines Mfg. Since 7/09 | O P E R A T I O N | Model SB1016/SB1036 |

3-Jaw Chuck

Refer to Chuck & Faceplate Mounting instructions on Page 35 to mount the

The

There are two sets of removable hardened steel jaws included with the

56). The outside of the jaws are used to hold the workpiece from the outer diameter.

Changing Jaws |

|

Item Needed | Qty |

Chuck Key | 1 |

White Lithium Grease | As Needed |

Chuck Cradle or Plywood 3⁄4" (to protect bed)...... 1 | |

To change the jaw:

1.DISCONNECT LATHE FROM POWER!

2.Place a piece of wood over the ways to protect them from potential damage.

3.Insert the chuck key and turn it counterclockwise to back the jaws out and remove them.

4.Clean the jaw mating surfaces and apply a thin film of white lithium grease to the mating surfaces.

5.Set the

6.Rotate the chuck key clockwise until you see the initial thread of the scroll gear just begin to enter jaw guide #1 (see Figure 58).

Figure 56. Chuck and jaw selection.

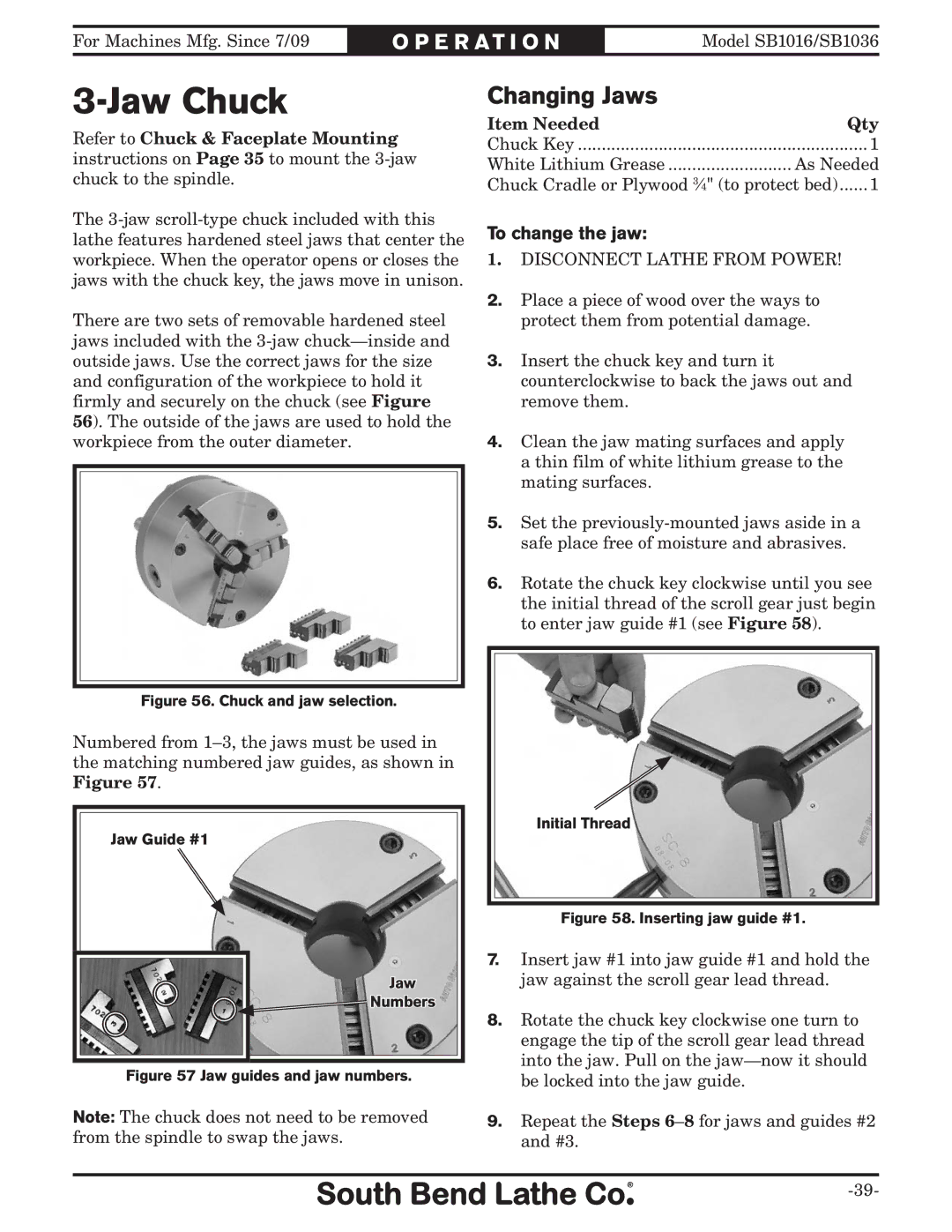

Numbered from

Jaw Guide #1 |

Jaw |

Numbers |

Figure 57 Jaw guides and jaw numbers.

Initial Thread

Figure 58. Inserting jaw guide #1.

7.Insert jaw #1 into jaw guide #1 and hold the jaw against the scroll gear lead thread.

8.Rotate the chuck key clockwise one turn to engage the tip of the scroll gear lead thread into the jaw. Pull on the

Note: The chuck does not need to be removed from the spindle to swap the jaws.

9.Repeat the Steps