Model SB1016/SB1036 | S E R V I C E | For Machines Mfg. Since 7/09 |

Leadscrew End Play Adjustment

After a long period of time, you may find that the leadscrew develops a small amount of end play. This lathe is designed so that leadscrew end play can be easily removed with adjustment.

Tools Needed: | Qty |

Open End Wrench 36mm or 17⁄16" | ........................ 1 |

Hex Wrench 3mm | 1 |

To remove leadscrew end play:

1.DISCONNECT LATHE FROM POWER!

2.Remove the three cap screws and end cover.

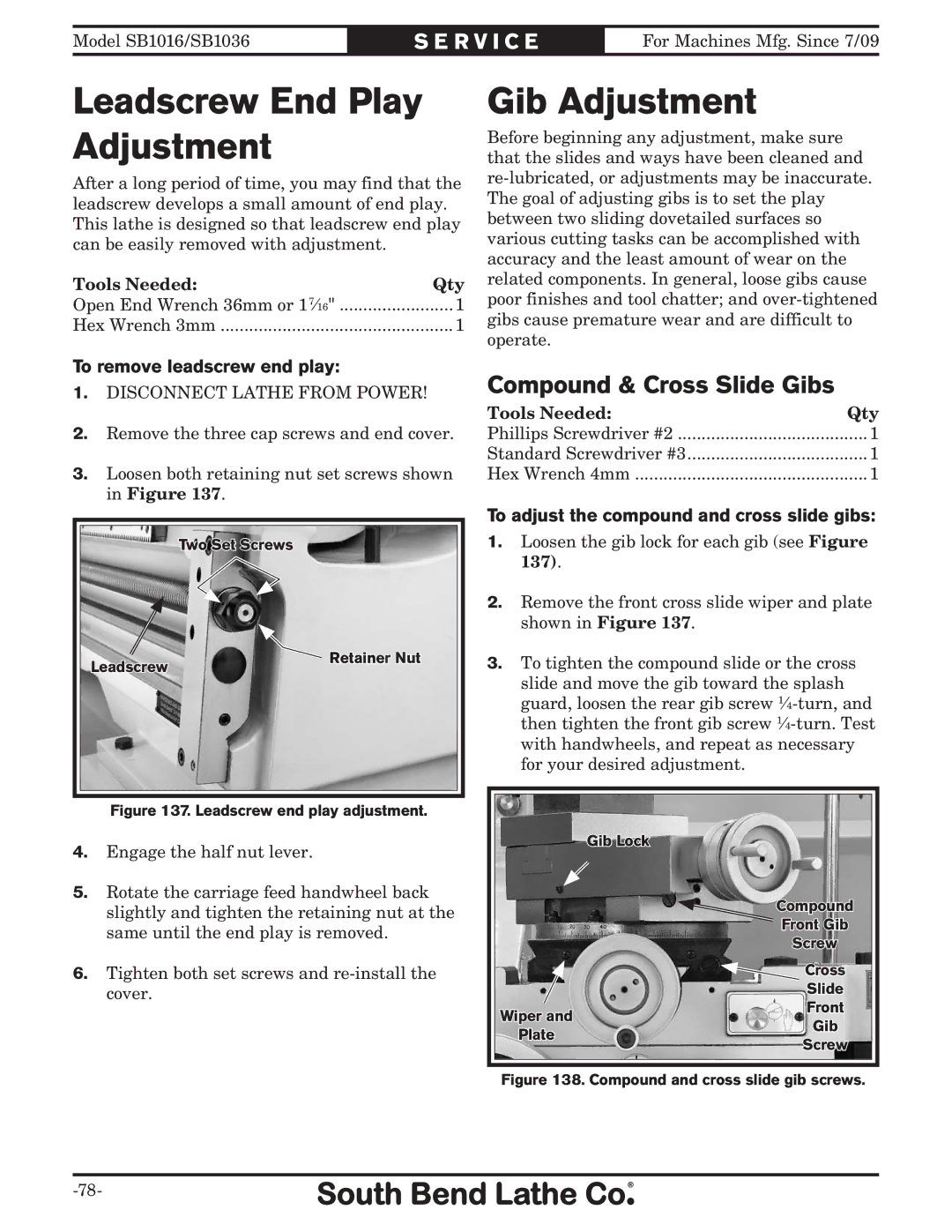

3.Loosen both retaining nut set screws shown in Figure 137.

Two Set Screws

Gib Adjustment

Before beginning any adjustment, make sure that the slides and ways have been cleaned and

Compound & Cross Slide Gibs |

|

Tools Needed: | Qty |

Phillips Screwdriver #2 | 1 |

Standard Screwdriver #3 | 1 |

Hex Wrench 4mm | 1 |

To adjust the compound and cross slide gibs:

1. | Loosen the gib lock for each gib (see Figure |

| 137). |

2. | Remove the front cross slide wiper and plate |

| shown in Figure 137. |

Leadscrew

![]() Retainer Nut

Retainer Nut

3. To tighten the compound slide or the cross |

slide and move the gib toward the splash |

guard, loosen the rear gib screw |

then tighten the front gib screw |

with handwheels, and repeat as necessary |

for your desired adjustment. |

Figure 137. Leadscrew end play adjustment.

4.Engage the half nut lever.

5.Rotate the carriage feed handwheel back slightly and tighten the retaining nut at the same until the end play is removed.

6.Tighten both set screws and

Gib Lock

Compound

Front Gib

Screw

![]() Cross

Cross

Slide

Wiper and

Front

Plate

Gib

Screw