For Machines Mfg. Since 7/09 | O P E R A T I O N | Model SB1016/SB1036 |

6.After the workpiece is held in place by the jaws, turn the chuck by hand and pay attention to the workpiece alignment.

—If the workpiece is not correctly aligned for your operation, turn the chuck and make fine adjustments by slightly loosening one jaw and tightening the opposing jaw until the workpiece is correctly aligned (see Figure 61 for an example).

Figure 61. Example of non-concentric workpiece

correctly mounted on the 4-jaw chuck.

Tailstock

The tailstock is typically used to support long workpieces by means of a live or dead center (refer to Centers on Page 47). It can also be used to hold a drill or chuck to bore holes in the center of a part. Custom arbors and tapers can also be cut on your lathe by using the off- set tailstock adjustment screws shown in (see Figure 63).

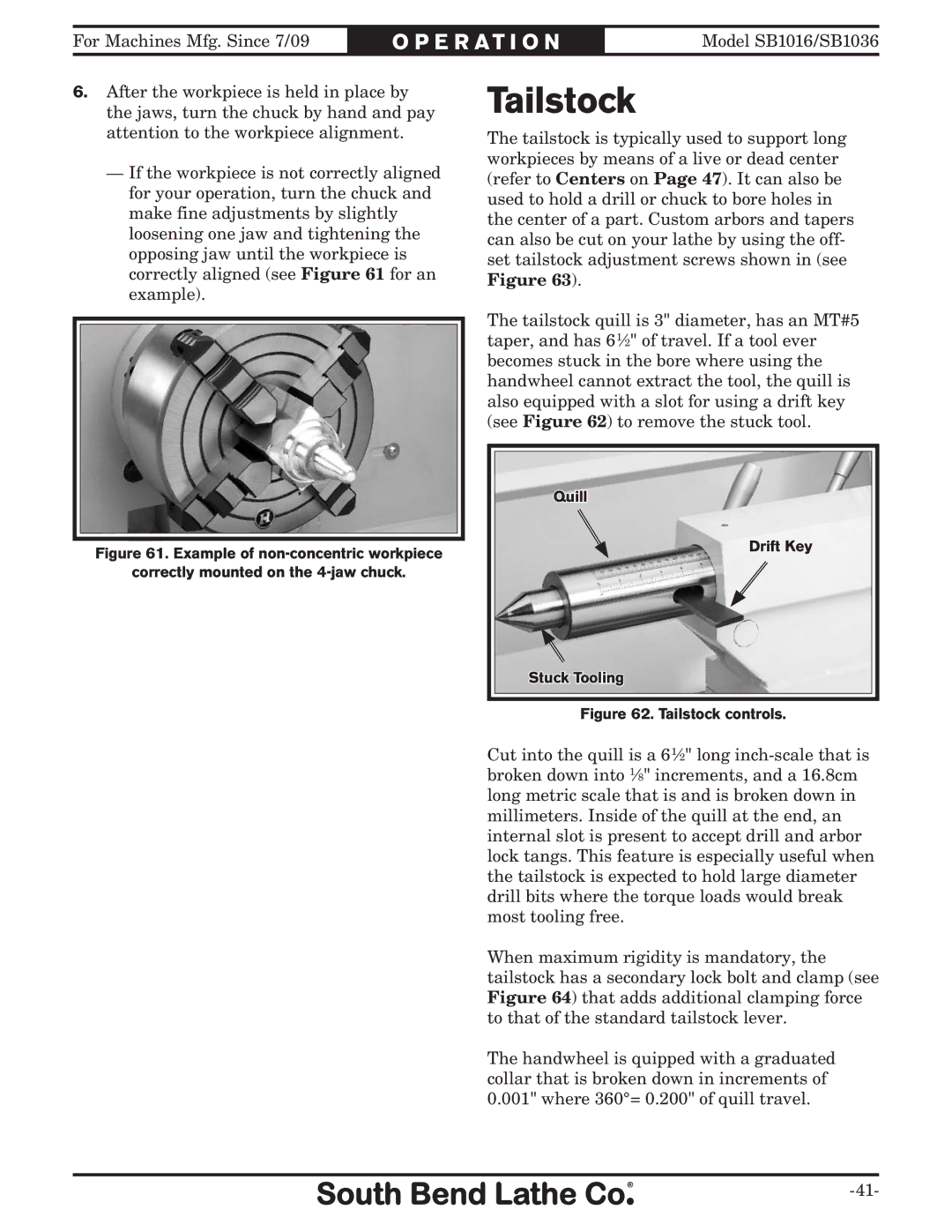

The tailstock quill is 3" diameter, has an MT#5 taper, and has 61⁄2" of travel. If a tool ever becomes stuck in the bore where using the handwheel cannot extract the tool, the quill is also equipped with a slot for using a drift key (see Figure 62) to remove the stuck tool.

Quill

Drift Key

Stuck Tooling

Figure 62. Tailstock controls.

Cut into the quill is a 61⁄2" long

When maximum rigidity is mandatory, the tailstock has a secondary lock bolt and clamp (see Figure 64) that adds additional clamping force to that of the standard tailstock lever.

The handwheel is quipped with a graduated collar that is broken down in increments of 0.001" where 360°= 0.200" of quill travel.