NOTES:

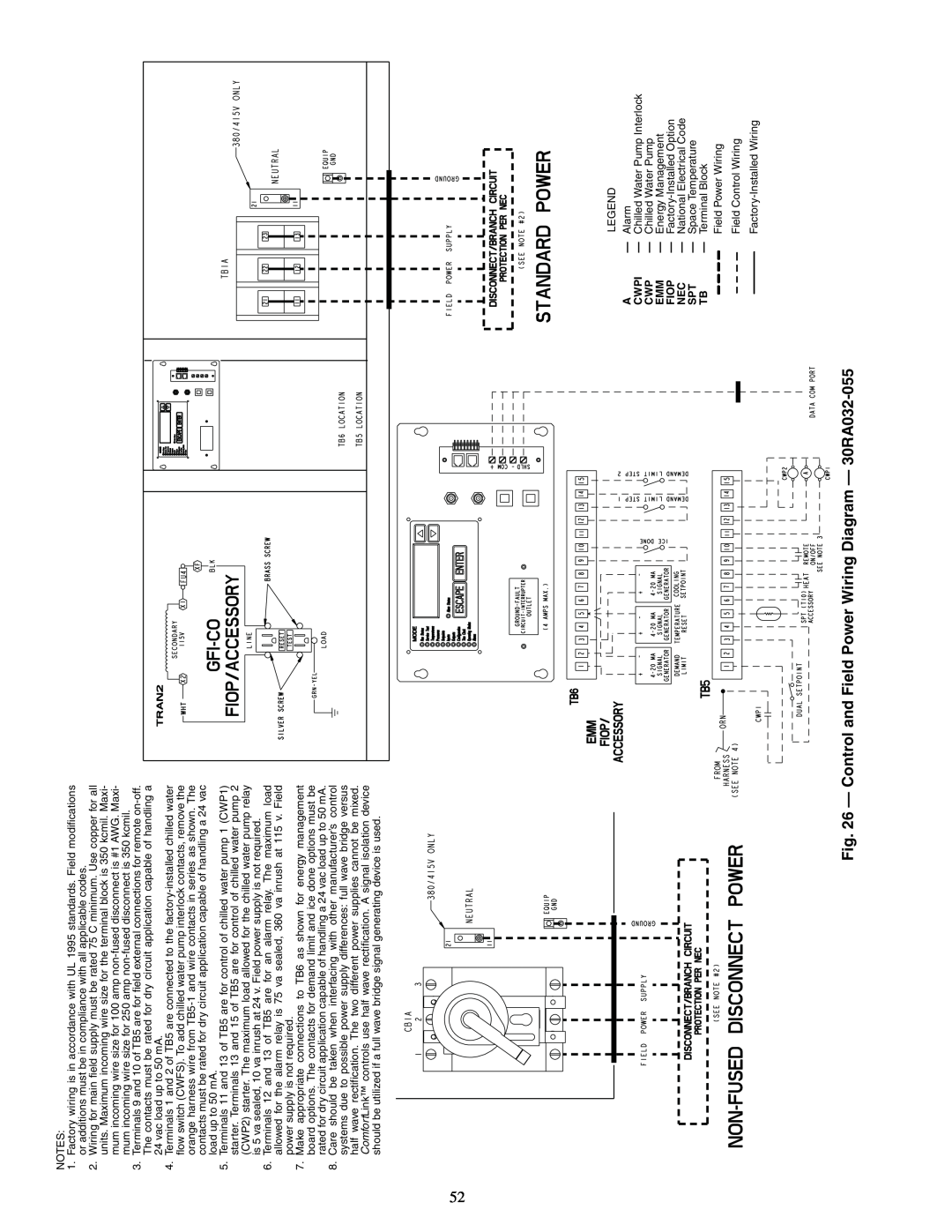

1.Factory wiring is in accordance with UL 1995 standards. Field modifications or additions must be in compliance with all applicable codes.

2.Wiring for main field supply must be rated 75 C minimum. Use copper for all units. Maximum incoming wire size for the terminal block is 350 kcmil. Maxi- mum incoming wire size for 100 amp

3.Terminals 9 and 10 of TB5 are for field external connections for remote

The contacts must be rated for dry circuit application capable of handling a 24 vac load up to 50 mA.

4. Terminals 1 and 2 of TB5 are connected to the

5. Terminals 11 and 13 of TB5 are for control of chilled water pump 1 (CWP1) starter. Terminals 13 and 15 of TB5 are for control of chilled water pump 2 (CWP2) starter. The maximum load allowed for the chilled water pump relay is 5 va sealed, 10 va inrush at 24 v. Field power supply is not required.

6. Terminals 12 and 13 of TB5 are for an alarm relay. The maximum load allowed for the alarm relay is 75 va sealed, 360 va inrush at 115 v. Field power supply is not required.

7. Make appropriate connections to TB6 as shown for energy management board options. The contacts for demand limit and ice done options must be rated for dry circuit application capable of handling a 24 vac load up to 50 mA.

8. Care should be taken when interfacing with other manufacturer’s control systems due to possible power supply differences: full wave bridge versus half wave rectification. The two different power supplies cannot be mixed. ComfortLink™ controls use half wave rectification. A signal isolation device should be utilized if a full wave bridge signal generating device is used.

52

| LEGEND |

A | — Alarm |

CWPI | — Chilled Water Pump Interlock |

CWP | — Chilled Water Pump |

EMM | — Energy Management |

FIOP | — |

NEC | — National Electrical Code |

SPT | — Space Temperature |

TB | — Terminal Block |

| Field Power Wiring |

| Field Control Wiring |

|

Fig. 26 — Control and Field Power Wiring Diagram —