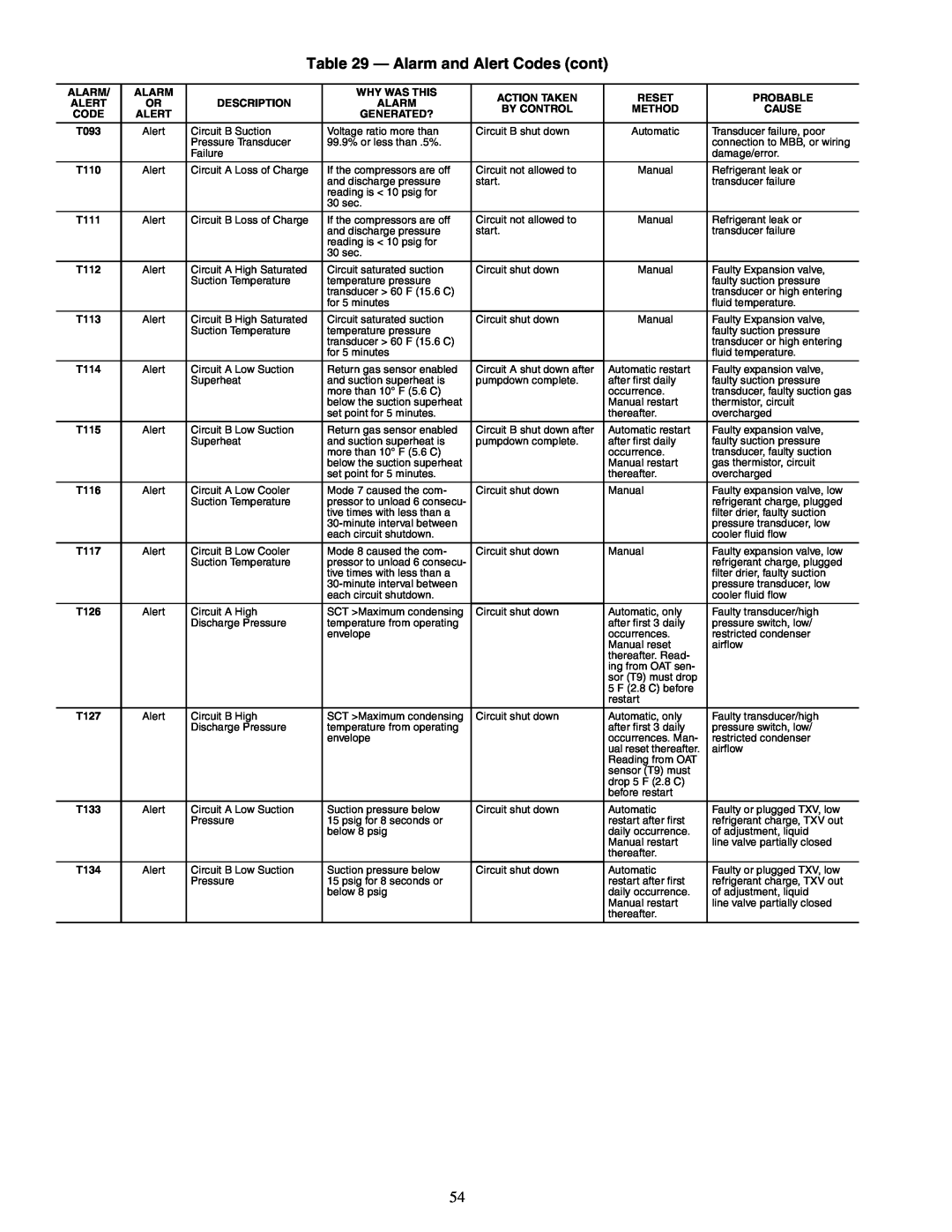

Table 29 — Alarm and Alert Codes (cont)

ALARM/ | ALARM |

| WHY WAS THIS | ACTION TAKEN | RESET | PROBABLE | |

ALERT | OR | DESCRIPTION | ALARM | ||||

BY CONTROL | METHOD | CAUSE | |||||

CODE | ALERT |

| GENERATED? | ||||

|

|

|

| ||||

|

|

|

|

|

|

| |

T093 | Alert | Circuit B Suction | Voltage ratio more than | Circuit B shut down | Automatic | Transducer failure, poor | |

|

| Pressure Transducer | 99.9% or less than .5%. |

|

| connection to MBB, or wiring | |

|

| Failure |

|

|

| damage/error. | |

T110 | Alert | Circuit A Loss of Charge | If the compressors are off | Circuit not allowed to | Manual | Refrigerant leak or | |

|

|

| and discharge pressure | start. |

| transducer failure | |

|

|

| reading is < 10 psig for |

|

|

| |

|

|

| 30 sec. |

|

|

| |

|

|

|

|

|

|

| |

T111 | Alert | Circuit B Loss of Charge | If the compressors are off | Circuit not allowed to | Manual | Refrigerant leak or | |

|

|

| and discharge pressure | start. |

| transducer failure | |

|

|

| reading is < 10 psig for |

|

|

| |

|

|

| 30 sec. |

|

|

| |

|

|

|

|

|

|

| |

T112 | Alert | Circuit A High Saturated | Circuit saturated suction | Circuit shut down | Manual | Faulty Expansion valve, | |

|

| Suction Temperature | temperature pressure |

|

| faulty suction pressure | |

|

|

| transducer > 60 F (15.6 C) |

|

| transducer or high entering | |

|

|

| for 5 minutes |

|

| fluid temperature. | |

T113 | Alert | Circuit B High Saturated | Circuit saturated suction | Circuit shut down | Manual | Faulty Expansion valve, | |

|

| Suction Temperature | temperature pressure |

|

| faulty suction pressure | |

|

|

| transducer > 60 F (15.6 C) |

|

| transducer or high entering | |

|

|

| for 5 minutes |

|

| fluid temperature. | |

T114 | Alert | Circuit A Low Suction | Return gas sensor enabled | Circuit A shut down after | Automatic restart | Faulty expansion valve, | |

|

| Superheat | and suction superheat is | pumpdown complete. | after first daily | faulty suction pressure | |

|

|

| more than 10° F (5.6 C) |

| occurrence. | transducer, faulty suction gas | |

|

|

| below the suction superheat |

| Manual restart | thermistor, circuit | |

|

|

| set point for 5 minutes. |

| thereafter. | overcharged | |

T115 | Alert | Circuit B Low Suction | Return gas sensor enabled | Circuit B shut down after | Automatic restart | Faulty expansion valve, | |

|

| Superheat | and suction superheat is | pumpdown complete. | after first daily | faulty suction pressure | |

|

|

| more than 10° F (5.6 C) |

| occurrence. | transducer, faulty suction | |

|

|

| below the suction superheat |

| Manual restart | gas thermistor, circuit | |

|

|

| set point for 5 minutes. |

| thereafter. | overcharged | |

T116 | Alert | Circuit A Low Cooler | Mode 7 caused the com- | Circuit shut down | Manual | Faulty expansion valve, low | |

|

| Suction Temperature | pressor to unload 6 consecu- |

|

| refrigerant charge, plugged | |

|

|

| tive times with less than a |

|

| filter drier, faulty suction | |

|

|

|

|

| pressure transducer, low | ||

|

|

| each circuit shutdown. |

|

| cooler fluid flow | |

T117 | Alert | Circuit B Low Cooler | Mode 8 caused the com- | Circuit shut down | Manual | Faulty expansion valve, low | |

|

| Suction Temperature | pressor to unload 6 consecu- |

|

| refrigerant charge, plugged | |

|

|

| tive times with less than a |

|

| filter drier, faulty suction | |

|

|

|

|

| pressure transducer, low | ||

|

|

| each circuit shutdown. |

|

| cooler fluid flow | |

T126 | Alert | Circuit A High | SCT >Maximum condensing | Circuit shut down | Automatic, only | Faulty transducer/high | |

|

| Discharge Pressure | temperature from operating |

| after first 3 daily | pressure switch, low/ | |

|

|

| envelope |

| occurrences. | restricted condenser | |

|

|

|

|

| Manual reset | airflow | |

|

|

|

|

| thereafter. Read- |

| |

|

|

|

|

| ing from OAT sen- |

| |

|

|

|

|

| sor (T9) must drop |

| |

|

|

|

|

| 5 F (2.8 C) before |

| |

|

|

|

|

| restart |

| |

T127 | Alert | Circuit B High | SCT >Maximum condensing | Circuit shut down | Automatic, only | Faulty transducer/high | |

|

| Discharge Pressure | temperature from operating |

| after first 3 daily | pressure switch, low/ | |

|

|

| envelope |

| occurrences. Man- | restricted condenser | |

|

|

|

|

| ual reset thereafter. | airflow | |

|

|

|

|

| Reading from OAT |

| |

|

|

|

|

| sensor (T9) must |

| |

|

|

|

|

| drop 5 F (2.8 C) |

| |

|

|

|

|

| before restart |

| |

T133 | Alert | Circuit A Low Suction | Suction pressure below | Circuit shut down | Automatic | Faulty or plugged TXV, low | |

|

| Pressure | 15 psig for 8 seconds or |

| restart after first | refrigerant charge, TXV out | |

|

|

| below 8 psig |

| daily occurrence. | of adjustment, liquid | |

|

|

|

|

| Manual restart | line valve partially closed | |

|

|

|

|

| thereafter. |

| |

T134 | Alert | Circuit B Low Suction | Suction pressure below | Circuit shut down | Automatic | Faulty or plugged TXV, low | |

|

| Pressure | 15 psig for 8 seconds or |

| restart after first | refrigerant charge, TXV out | |

|

|

| below 8 psig |

| daily occurrence. | of adjustment, liquid | |

|

|

|

|

| Manual restart | line valve partially closed | |

|

|

|

|

| thereafter. |

|

54