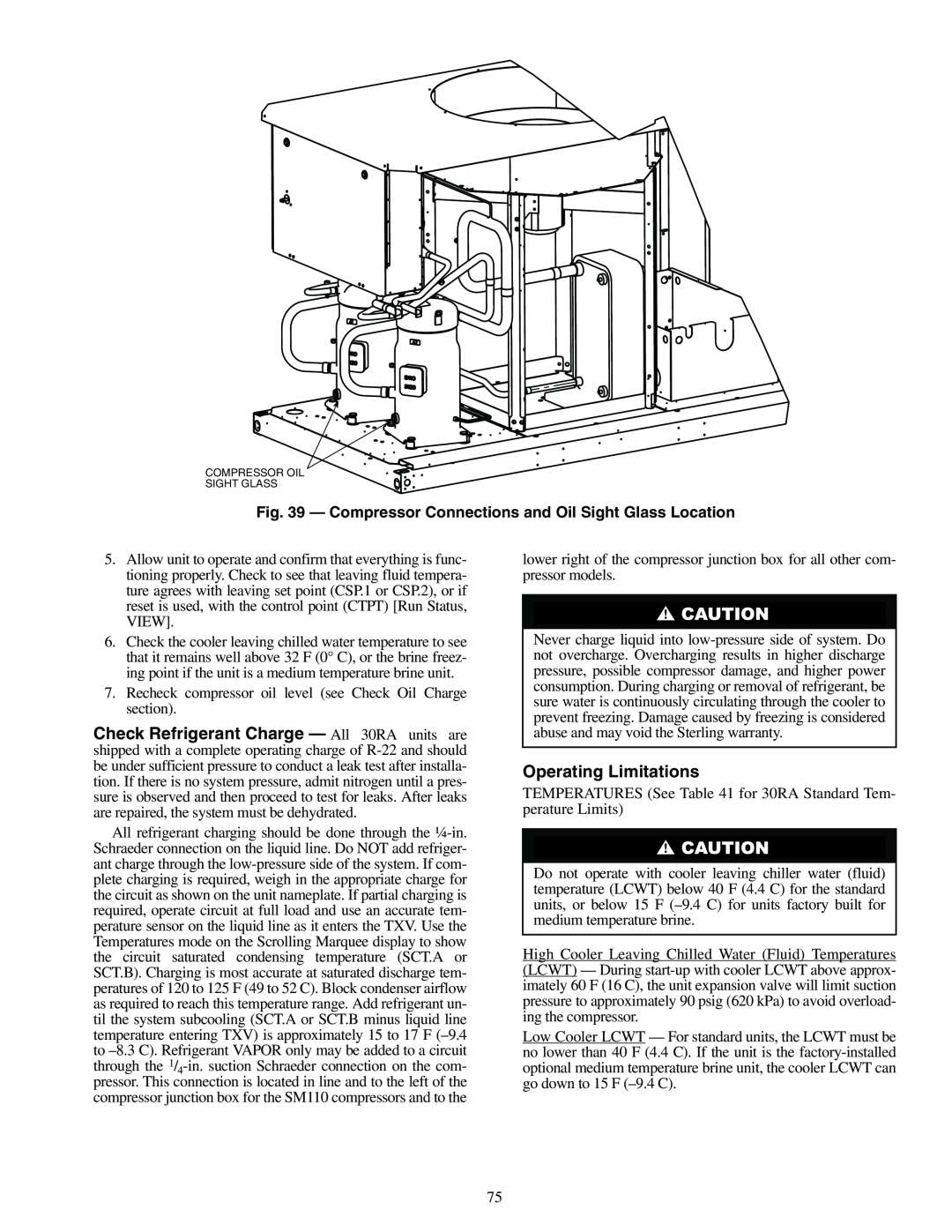

COMPRESSOR OIL

SIGHT GLASS

Fig. 39 — Compressor Connections and Oil Sight Glass Location

5.Allow unit to operate and confirm that everything is func- tioning properly. Check to see that leaving fluid tempera- ture agrees with leaving set point (CSP.1 or CSP.2), or if reset is used, with the control point (CTPT) [Run Status, VIEW].

6.Check the cooler leaving chilled water temperature to see that it remains well above 32 F (0° C), or the brine freez- ing point if the unit is a medium temperature brine unit.

7.Recheck compressor oil level (see Check Oil Charge section).

Check Refrigerant Charge — All 30RA units are shipped with a complete operating charge of

All refrigerant charging should be done through the

lower right of the compressor junction box for all other com- pressor models.

Never charge liquid into

Operating Limitations

TEMPERATURES (See Table 41 for 30RA Standard Tem- perature Limits)

Do not operate with cooler leaving chiller water (fluid) temperature (LCWT) below 40 F (4.4 C) for the standard units, or below 15 F

High Cooler Leaving Chilled Water (Fluid) Temperatures (LCWT) — During

Low Cooler LCWT — For standard units, the LCWT must be no lower than 40 F (4.4 C). If the unit is the

75