NOTE: The rotor set consists of the rotor (19), vanes (20), and stator (21). Rotor set components may be- come disassembled during service procedures. Do not service separately.

NOTE: It may be necessary to turn one alignment stud out of the housing (3) temporarily to assemble rotor set over the drive link (13).

NOTE: The rotor set rotor counterbore side must be down against wear plate for drive link clearance and to maintain the original

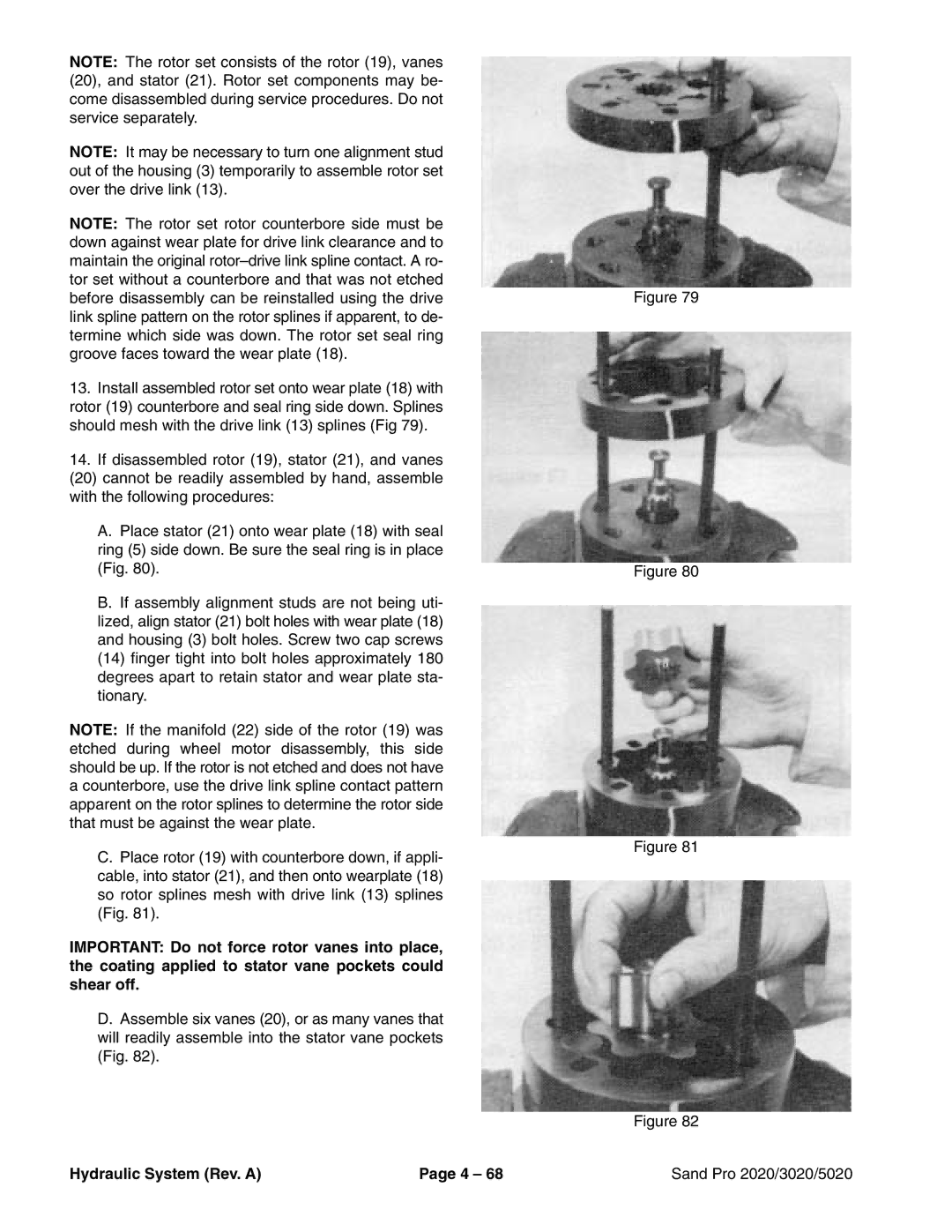

13.Install assembled rotor set onto wear plate (18) with rotor (19) counterbore and seal ring side down. Splines should mesh with the drive link (13) splines (Fig 79).

14.If disassembled rotor (19), stator (21), and vanes (20) cannot be readily assembled by hand, assemble with the following procedures:

A.Place stator (21) onto wear plate (18) with seal ring (5) side down. Be sure the seal ring is in place (Fig. 80).

B.If assembly alignment studs are not being uti- lized, align stator (21) bolt holes with wear plate (18) and housing (3) bolt holes. Screw two cap screws (14) finger tight into bolt holes approximately 180 degrees apart to retain stator and wear plate sta- tionary.

NOTE: If the manifold (22) side of the rotor (19) was etched during wheel motor disassembly, this side should be up. If the rotor is not etched and does not have a counterbore, use the drive link spline contact pattern apparent on the rotor splines to determine the rotor side that must be against the wear plate.

C.Place rotor (19) with counterbore down, if appli- cable, into stator (21), and then onto wearplate (18) so rotor splines mesh with drive link (13) splines (Fig. 81).

IMPORTANT: Do not force rotor vanes into place, the coating applied to stator vane pockets could shear off.

D.Assemble six vanes (20), or as many vanes that will readily assemble into the stator vane pockets (Fig. 82).

Hydraulic System (Rev. A) | Page 4 – 68 |

Figure 79

Figure 80

Figure 81

Figure 82