Troubleshooting

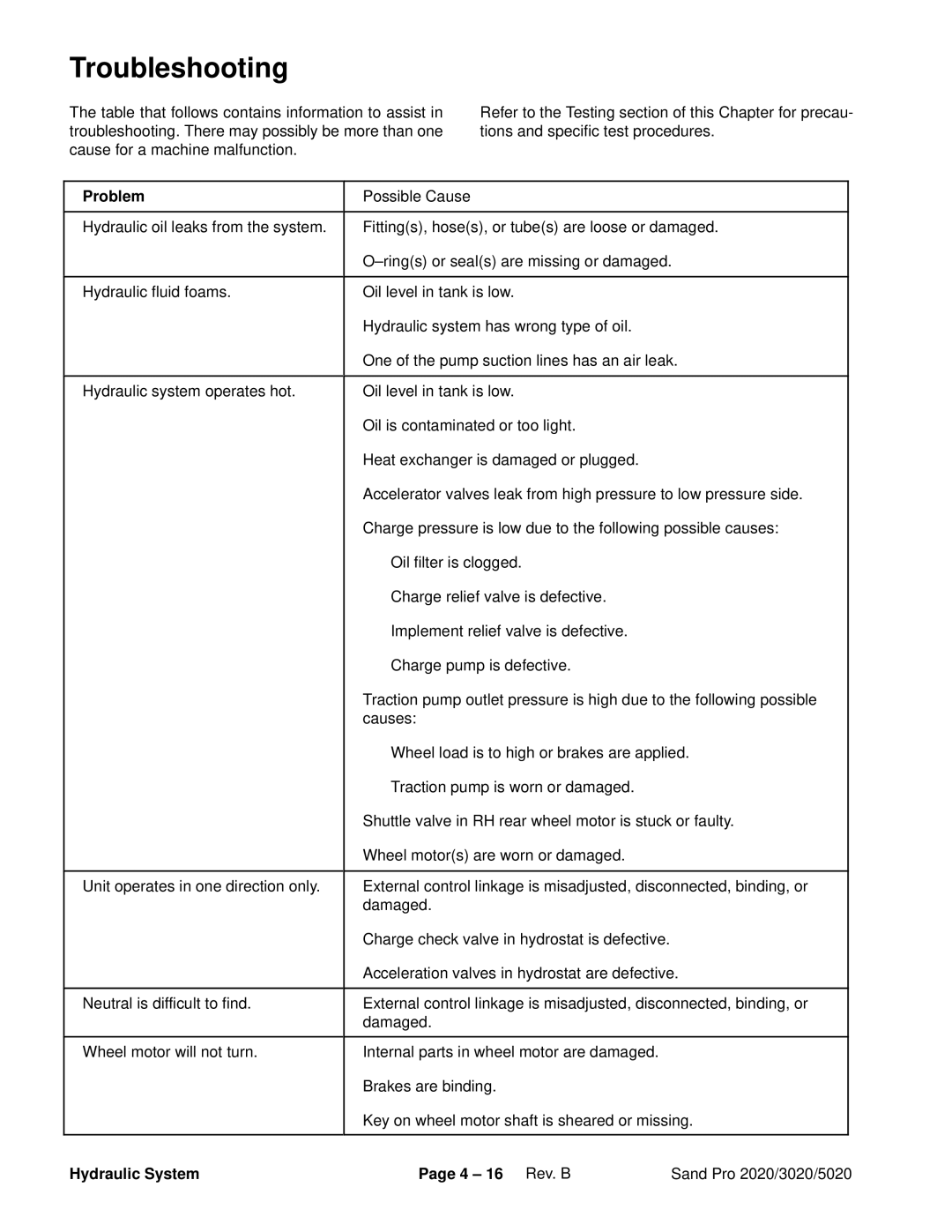

The table that follows contains information to assist in troubleshooting. There may possibly be more than one cause for a machine malfunction.

Refer to the Testing section of this Chapter for precau- tions and specific test procedures.

Problem | Possible Cause |

|

|

Hydraulic oil leaks from the system. | Fitting(s), hose(s), or tube(s) are loose or damaged. |

| |

|

|

Hydraulic fluid foams. | Oil level in tank is low. |

| Hydraulic system has wrong type of oil. |

| One of the pump suction lines has an air leak. |

|

|

Hydraulic system operates hot. | Oil level in tank is low. |

| Oil is contaminated or too light. |

| Heat exchanger is damaged or plugged. |

| Accelerator valves leak from high pressure to low pressure side. |

| Charge pressure is low due to the following possible causes: |

| Oil filter is clogged. |

| Charge relief valve is defective. |

| Implement relief valve is defective. |

| Charge pump is defective. |

| Traction pump outlet pressure is high due to the following possible |

| causes: |

| Wheel load is to high or brakes are applied. |

| Traction pump is worn or damaged. |

| Shuttle valve in RH rear wheel motor is stuck or faulty. |

| Wheel motor(s) are worn or damaged. |

|

|

Unit operates in one direction only. | External control linkage is misadjusted, disconnected, binding, or |

| damaged. |

| Charge check valve in hydrostat is defective. |

| Acceleration valves in hydrostat are defective. |

|

|

Neutral is difficult to find. | External control linkage is misadjusted, disconnected, binding, or |

| damaged. |

|

|

Wheel motor will not turn. | Internal parts in wheel motor are damaged. |

| Brakes are binding. |

| Key on wheel motor shaft is sheared or missing. |

|

|

Hydraulic System | Page 4 – 16 Rev. B | Sand Pro 2020/3020/5020 |