Lift Cylinder(SP 5020)

Removal

1.Before removing any parts from the hydraulic sys- tem, park the machine on a level surface, engage the parking brake, lower the cutting units, and stop the en- gine.

![]() CAUTION

CAUTION

Operate all hydraulic controls to relieve system pressure and avoid injury from pressurized hy- draulic oil. Controls must be operated with the ignition switch in OFF. Remove key from the igni- tion switch.

2.Label all hydraulic connections for reassembly.

3.Disconnect hydraulic hoses and

4.Put caps or plugs on disconnected hoses and fit- tings to prevent contamination.

5.Remove both hair pins from the cylinder pin. Pull cylinder pin from the lift cylinder, spacer, and lift arm.

6.Support lift cylinder to prevent it from dropping.

A.Remove cap screw and flat washer from the cyl- inder support.

B.Remove lift cylinder from the support.

Installation

1.Position lift cylinder to the frame. Install lift cylinder to to the cylinder support. Secure cylinder to the support with flat washer and cap screw.

2.Position clevis of the lift cylinder to the lift arm and spacer. Insert cylinder pin through the cylinder clevis, lift arm, and spacer. Secure cylinder pin with both hair pins.

3.Remove caps or plugs from the disconnected hoses and fittings. Connect hydraulic hoses and

4.Charge hydraulic system (see Charge Hydraulic System).

|

| 18 | 1 | 2 3 |

|

| 17 |

| 4 |

|

|

|

| |

|

| 13 |

|

|

11 |

| 15 | 16 |

|

| 14 |

| ||

12 |

|

| ||

| 13 |

|

| |

|

|

|

| |

9 |

|

|

|

|

10 |

|

|

|

|

|

| 5 |

|

|

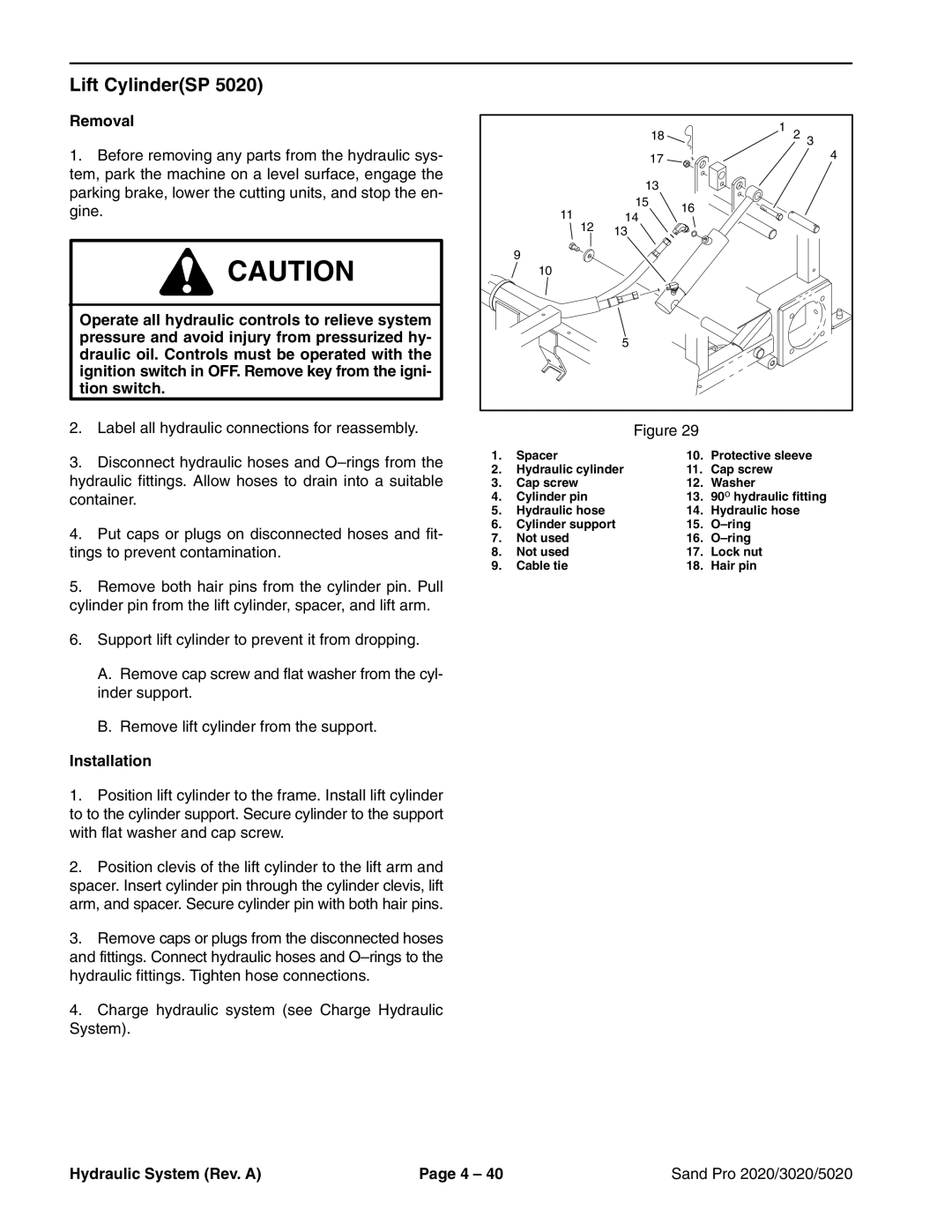

Figure 29

1. | Spacer | 10. | Protective sleeve |

2. | Hydraulic cylinder | 11. | Cap screw |

3. | Cap screw | 12. | Washer |

4. | Cylinder pin | 13. | 90o hydraulic fitting |

5. | Hydraulic hose | 14. | Hydraulic hose |

6. | Cylinder support | 15. | |

7. | Not used | 16. | |

8. | Not used | 17. | Lock nut |

9. | Cable tie | 18. | Hair pin |

Hydraulic System (Rev. A) | Page 4 – 40 | Sand Pro 2020/3020/5020 |