AIR-CONDITIONER

Contents

New Refrigerant Air Conditioner Installation

For general public use

For Reference

Specifications

Specifications

RAS-10SKVP-ND RAS-13SKVP-ND RAS-16SKVP-ND

Operation Characteristic Curve

Heating

Cooling

Current

Capacity Variation Ratio According to Temperature

Cooling

Heating

Capacity ratio % 110 100

Safety During Installation/Servicing

Refrigerant Piping Installation

Piping Materials and Joints Used

Copper Pipes

Processing of Piping Materials

Flare processing procedures and precautions

Joints

Flare tool for R410A Conventional flare tool

Clutch type Wing nut type

Flare tool for R22 Conventional flare tool

Diameter

Nm kgfcm

Flare Connecting Procedures and Precautions

Wrenches available on the market

Required Tools

Tools

General tools Conventional tools can be used

1 Configuration of refrigerant charging

Recharging of Refrigerant

Materials for Brazing

Brazing of Pipes

Flux

Brazing

Never use gas other than Nitrogen gas

Construction Views

Indoor Unit

WH-H05JE

Mounting dimensions of anchor bolt

Outdoor Unit

Detailed a leg part

Detailed B leg part

Board

MCC-5009

MCC-5045

RAS-10SAVP-ND, RAS-13SAVP-ND, RAS-16SAVP-ND

Parts name Type Specifications

MP24Z3N

Parts name Model name Rating

CAM-MD12TF DC12V

Refrigerant Cycle Diagram

CAM-B22YGTF-3

Operation Data Cooling

Sleep Mode

Operation START/STOP Operation Mode Selection

AUTO, COOL, DRY, Heat

For Indoor Unit

Outdoor Unit Inverter Assembly

MCC5009 P.C.B

Outline of Air Conditioner Control

Role of indoor unit controller

Role of outdoor unit controller

Operations followed to

Filter Indicator

Remote Controller and Its Fuctions

Operation Description

Auto Restart Function

Remote controller

Indoor unit

Outdoor unit

ON/OFF

Auto operation

DRY operation

Indication Fan speed

Symbols

Indoor fan air flow rate

Operation flow and applicable data, etc Description

Heating operation

Indication Fan speed

Cold draft preventive control

Outdoor temperature To

Mode, by the conditions

Outdoor fan shown

Table is selected

Remote controller Indoor unit

When temperature of the indoor

Exchanger detects evaporation temperature and controls

Compressor speed so that temperature of the heat

Exchanger detects condensation temperature

Operation flow and applicable data, etc

Case of operation stop

Condition

Defrost operation

Louver position in cooling operation

Louver position in heating operation

Louver position in dry operation

Air direction

Mode

Sleep

Cooling operation

When keeping Reset button pushed for

If the filter lamp goes on, push Reset

Push Reset button again

Temporary

Purpose

Operation

Setup value Power OFF

SH control Release control PMV open degree control Stop by

Clean operation

Setting the clean operation cancel

Setting the clean operation

This completes the clean operation setting

Indoor P.C. board

Setting the remote controller

Setting the unit

Heat operation

Indoor control P.C. board At shipment Purpose

8C Heat operation -ND model only

Outdoor

To reduce noise, Reset button

With Quiet control/Non-select method Purpose

Start

During stop of air conditioner

During operation of air conditioner

On 8˚C Heat

Basic fan control

Indoor fan control

Auto TSC

Compressor speed control Refer to 4. Capacity control

To temp Heater output Operation

Base plate cord heater control Purpose

OFF

When the unit is standby Not operating

How to Set the Auto Restart Function

When the unit is in operation

Power Failure During Timer Operation

How to Turn Off Filter Indicator

When the system is on stand-by not operating

When the system is operating

Parts Name of Remote Controller

Display

Automatic operation

For the rear left and left piping

Safety Cautions

Do not allow the drain hose to become slack

Optional Installation Parts

Optional Parts, Accessories and Tools

Accessory and Installation Parts

Installation/Servicing Tools

New tools for R410A

Changes in the product and components

New tools for R410A Applicable to R22 model Changes

Installation Location

Remote controller

Drilling and Mounting Installation Plate

Mounting the installation plate

When the installation plate is directly mounted on the wall

Wiring Connection How to connect the connecting cable

Electrical Work

Anchor bolt Projection 15mm or less

How to remove the drain cap

How to remove the drain hose

Die-cutting front panel slit

Changing drain hose

How to attach the drain cap

How to attach the drain hose

Case of bottom right or bottom left piping

Left-hand connection with piping

Drainage

Indoor Unit Installation

Shield pipe Drain hose Inside the room

Precautions for adding refrigerant

Strong wind

Draining the Water

Refrigerant Piping Connection Flaring

Projection margin in flaring a Unit mm

Flaring size B Unit mm

Use a vacuum pump

Tightening Connection

To secure To tighten

Packed Valve handling precautions

Wiring Connection

Stripping length of connecting cable

Model RAS

Test Operation

Precautions when handling the new inverter 3DV Inverter

Troubleshooting Procedure

Control circuitry has an uninsulated construction

JAVP-E series insulated type

Do not lay the circuit board assembly flat

Discharging method

Sensor leads

Inverter cover

Confirmation of Power Supply

Confirmation of Power Voltage

First Confirmation

Operation Which is not a Trouble Program Operation

Primary Judgment

Judgment by Flashing LED of Indoor Unit

Which lamp does flash?

Check Block display Description for self-diagnosis Code

Self-Diagnosis by Remote Controller Check Code

How to Use Remote Controller in Service Mode

Push START/STOP button to release the service mode

Push on or OFF button

Block distinction

Judgment and action

Air Block Cause of operation

Remarks

Block Cause of operation

Judgment of Trouble by Every Symptom

Indoor Unit Including Remote Controller

Confirmation procedure

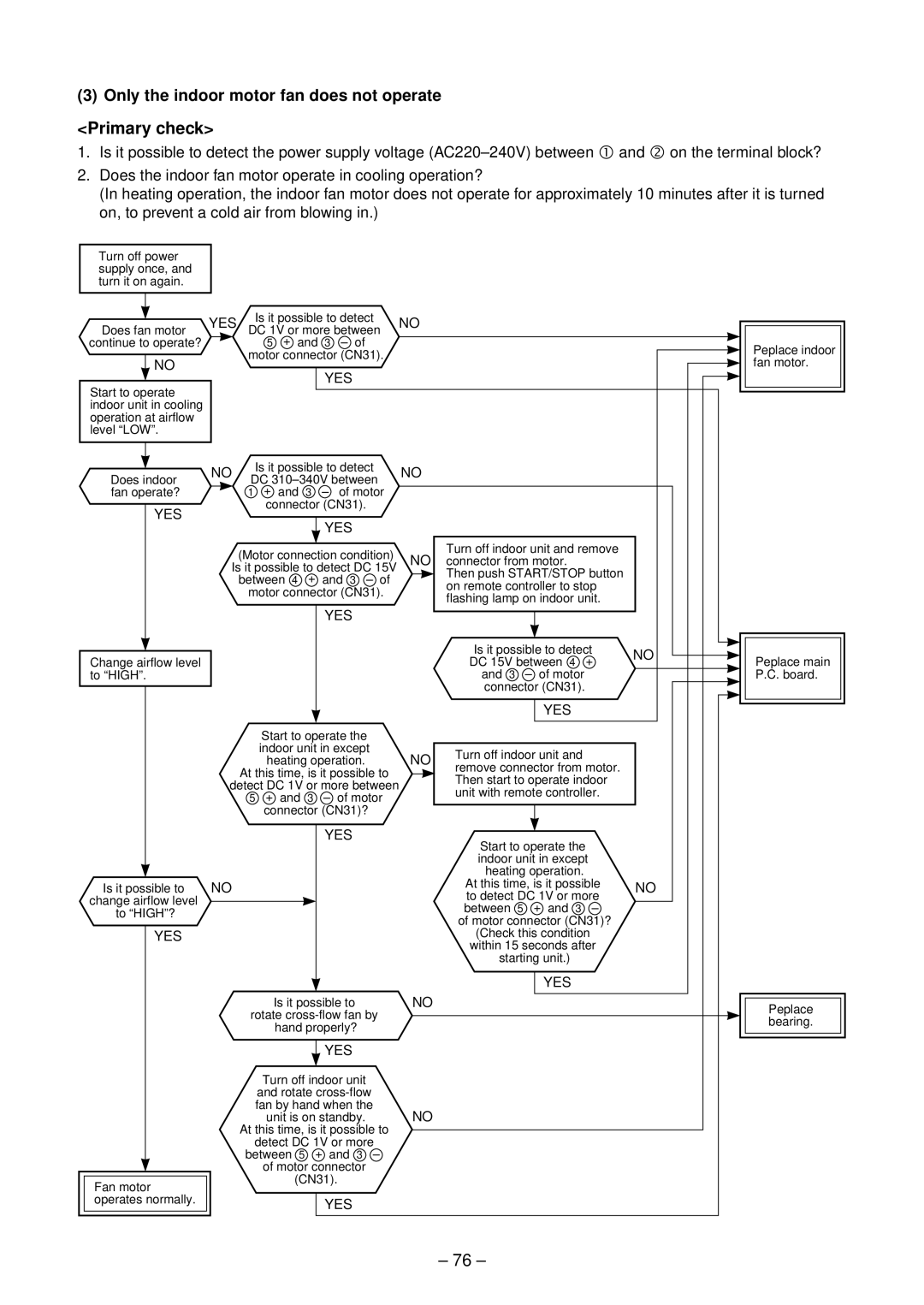

Primary check

Only the indoor motor fan does not operate

Inspection procedure

Cause

Troubleshooting for remote controller

Wiring Failure Interconnecting and Serial Signal Wire

Check procedure Select phenomena described below

Outdoor unit does not operate

Terminal block at indoor side

Check procedure

Check Code 1C Miswiring in indoor/outdoor units and 1E

1C1E

Troubleshooting

How to Check Whether the Air Purifier is Good or Not

Conduction check of micro-switch

Primary check

Summarized Inner Diagnosis of Inverter Assembly

How to Diagnose Trouble in Outdoor Unit

Diagnosis/Process flowchart Contents Summary

How to Check Simply the Main Parts

How to Check the P.C. Board Indoor Unit

Operating precautions

Inspection procedures

Check procedures

Procedure Check points Causes

OPERATION, TIMER, Filter

Cool

Sensor characteristic table

11-9-2. P.C. Board Layout

Indoor Unit Other Parts

Part name Checking procedure

Outdoor Unit

Case that product is good

Checking Method for Each Part

Tester rod Resistance value Good product

Symptom

Cause

Part name Procedures Remarks

12-1 Indoor Unit

How to assemble the front panel

How to assemble the high voltage generator

How to assemble the electric parts box

Slide the horizontal

Remove the two screws used to secure Bearing base

Pull out here

Drain pipe

Microcomputer

Part name Procedure Remarks

Board layout

No. Part name Procedure Remarks Common 1. Detachment

Attachment

No. Part name Procedure Remarks

Some cases

100

STIT-4X8MSZN

Disconnect the leads and connectors connected to

Other parts from the control board assembly

101

Board base

102

Side cabinet left

103

104

Handling precaution

Detachment

105

Detail a Arrow D Detail C

Detail B

Detail a Arrow D

Parts name Qty Remarks

106

Part name

MCC-5009

107

MCC-5009-04

240

237

108

Part Description

402 407, 408 403 406 404 405 410401

109

110

402 411, 412 403 406 404 405 410401

111

13, 16, 19 14, 15, 17 20, 21, 23, 24

112

113

13, 16, 19 14, 15, 17 20, 21, 23, 24 CORD, HEATER, Ass’y

114

115

13-3. P.C. Board Layout

116

117

Corresponding

118

Model

Toshiba Carrier Corporation