Print media

Preventing jams

By carefully selecting appropriate print media and loading it properly, you should be able to avoid most jams. If you do experience a jam, see Clearing jams for instructions.

The following hints can help you avoid jams:

•Use only recommended print media.

•Do not load wrinkled, creased, damp, or curled print media.

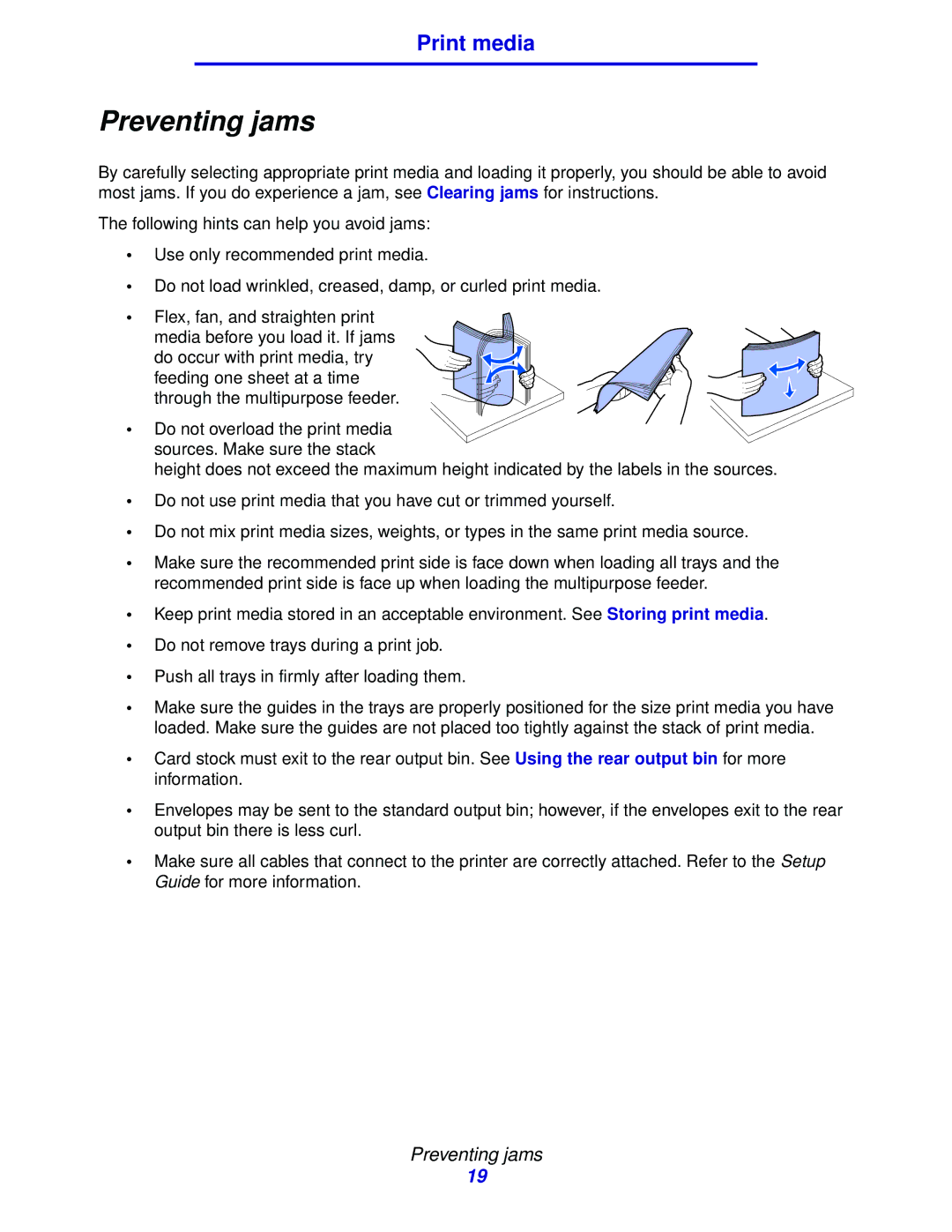

•Flex, fan, and straighten print

media before you load it. If jams do occur with print media, try feeding one sheet at a time through the multipurpose feeder.

•Do not overload the print media sources. Make sure the stack

height does not exceed the maximum height indicated by the labels in the sources.

•Do not use print media that you have cut or trimmed yourself.

•Do not mix print media sizes, weights, or types in the same print media source.

•Make sure the recommended print side is face down when loading all trays and the recommended print side is face up when loading the multipurpose feeder.

•Keep print media stored in an acceptable environment. See Storing print media.

•Do not remove trays during a print job.

•Push all trays in firmly after loading them.

•Make sure the guides in the trays are properly positioned for the size print media you have loaded. Make sure the guides are not placed too tightly against the stack of print media.

•Card stock must exit to the rear output bin. See Using the rear output bin for more information.

•Envelopes may be sent to the standard output bin; however, if the envelopes exit to the rear output bin there is less curl.

•Make sure all cables that connect to the printer are correctly attached. Refer to the Setup Guide for more information.

Preventing jams

19