SECTION 2 | TROUBLESHOOTING |

|

|

TROUBLESHOOTING

MOTOR TESTING (FIGURE 2)

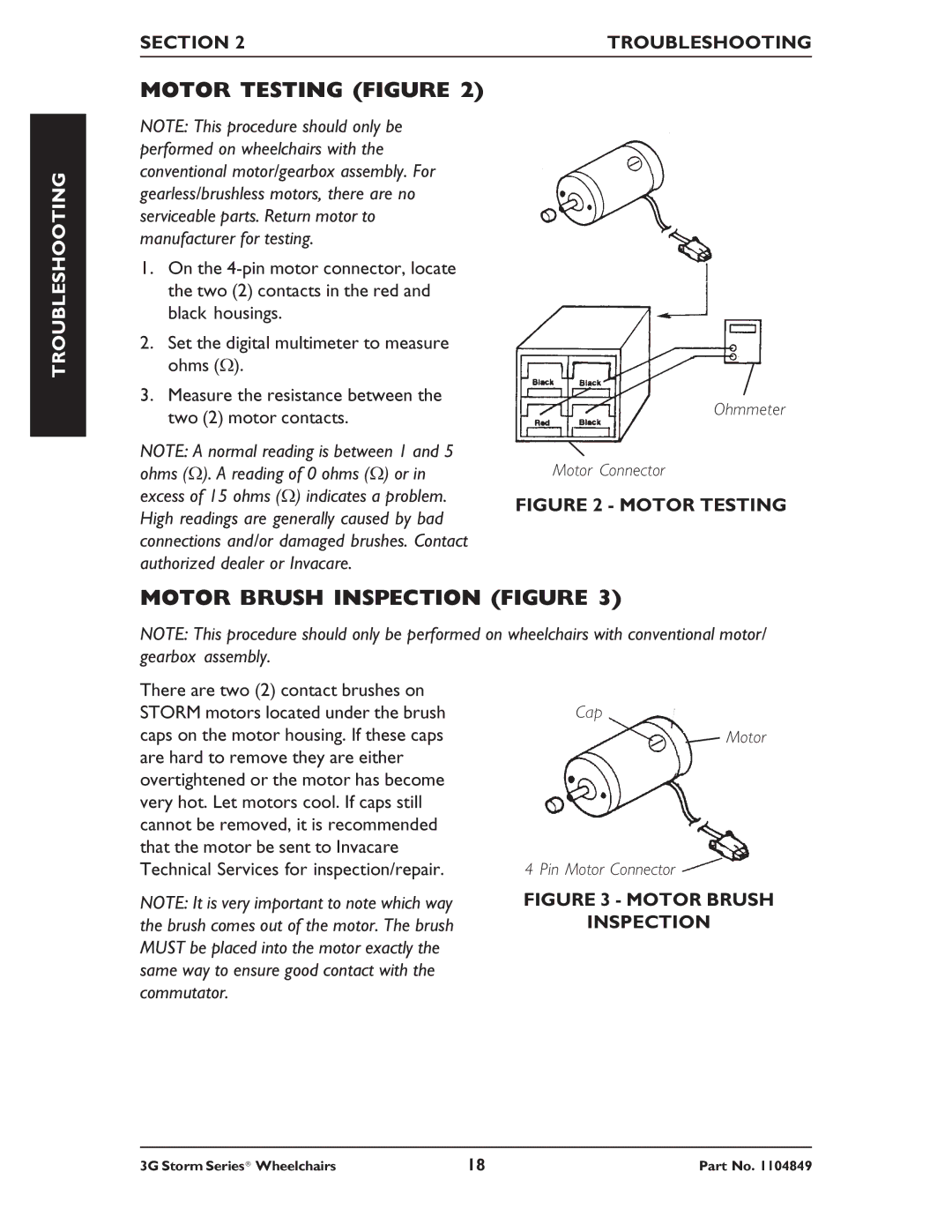

NOTE: This procedure should only be performed on wheelchairs with the conventional motor/gearbox assembly. For gearless/brushless motors, there are no serviceable parts. Return motor to manufacturer for testing.

1.On the

2.Set the digital multimeter to measure ohms (Ω).

3.Measure the resistance between the two (2) motor contacts.

NOTE: A normal reading is between 1 and 5 ohms (Ω). A reading of 0 ohms (Ω) or in excess of 15 ohms (Ω) indicates a problem. High readings are generally caused by bad connections and/or damaged brushes. Contact authorized dealer or Invacare.

Ohmmeter

Ohmmeter

Motor Connector

Motor Connector

FIGURE 2 - MOTOR TESTING

MOTOR BRUSH INSPECTION (FIGURE 3)

NOTE: This procedure should only be performed on wheelchairs with conventional motor/ gearbox assembly.

There are two (2) contact brushes on STORM motors located under the brush caps on the motor housing. If these caps are hard to remove they are either overtightened or the motor has become very hot. Let motors cool. If caps still cannot be removed, it is recommended that the motor be sent to Invacare Technical Services for inspection/repair.

NOTE: It is very important to note which way the brush comes out of the motor. The brush MUST be placed into the motor exactly the same way to ensure good contact with the commutator.

Cap

Motor

4 Pin Motor Connector

FIGURE 3 - MOTOR BRUSH

INSPECTION

3G Storm Series® Wheelchairs | 18 | Part No. 1104849 |