Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

|

|

|

|

|

|

| |||

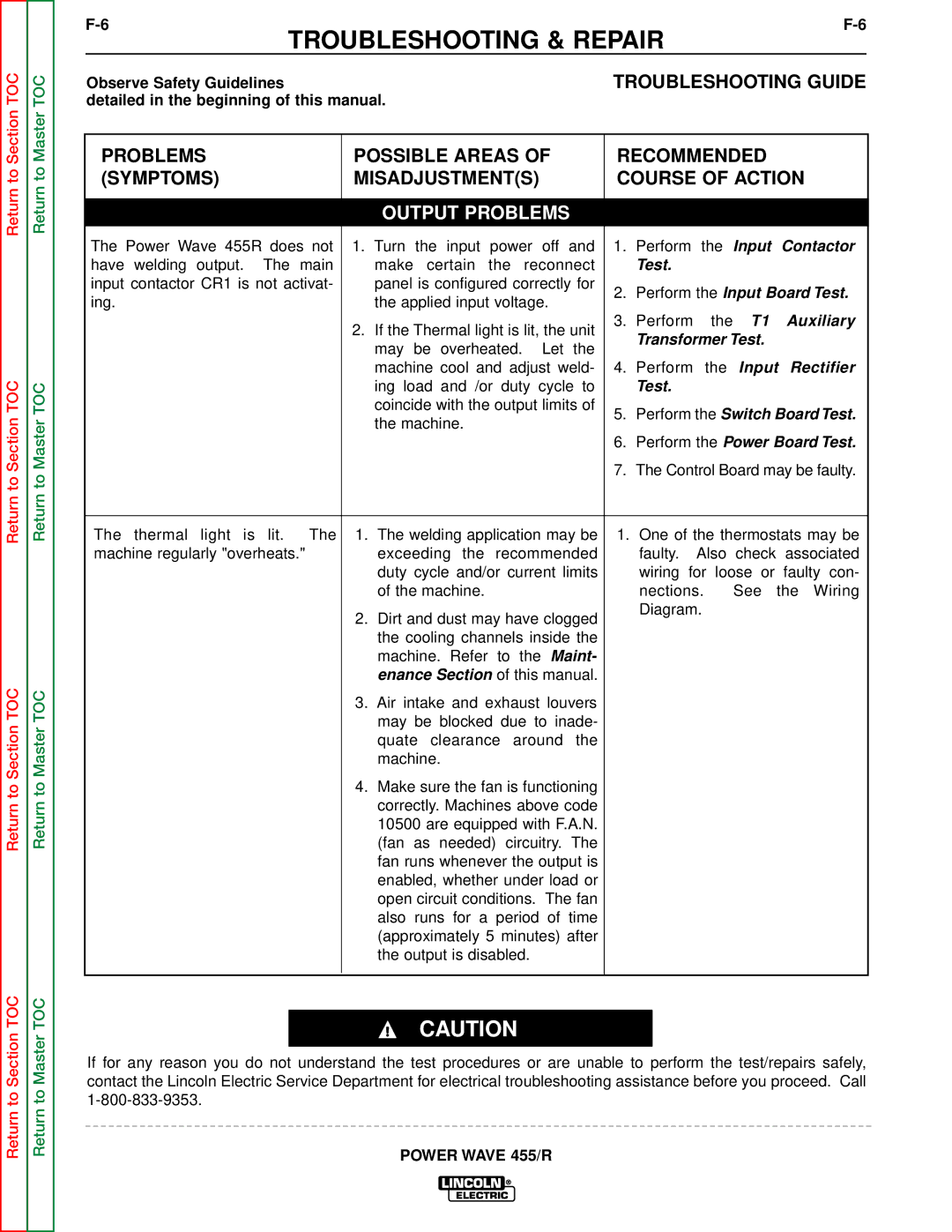

TROUBLESHOOTING & REPAIR |

|

|

|

| |||||

Observe Safety Guidelines |

|

| TROUBLESHOOTING GUIDE | ||||||

detailed in the beginning of this manual. |

|

|

|

|

|

|

| ||

|

|

|

|

|

| ||||

PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED |

|

| ||||

(SYMPTOMS) |

| MISADJUSTMENT(S) | COURSE OF ACTION | ||||||

|

|

|

|

|

|

|

|

|

|

|

| OUTPUT PROBLEMS |

|

|

|

|

|

|

|

The Power Wave 455R does not | 1. Turn the input power off and | 1. | Perform | the | Input | Contactor | |||

have welding output. The | main | make certain the reconnect |

|

| Test. |

|

|

|

|

input contactor CR1 is not activat- | panel is configured correctly for | 2. |

| Perform the Input Board Test. | |||||

ing. |

| the applied input voltage. |

| ||||||

|

|

|

|

|

|

|

| ||

|

| 2. If the Thermal light is lit, the unit | 3. |

| Perform | the | T1 | Auxiliary | |

|

|

|

| Transformer Test. |

|

| |||

|

| may be overheated. Let the |

|

|

|

| |||

|

|

|

|

|

|

|

|

| |

|

| machine cool and adjust weld- | 4. | Perform | the | Input | Rectifier | ||

|

| ing load and /or duty cycle to |

|

| Test. |

|

|

|

|

|

| coincide with the output limits of | 5. |

| Perform the Switch Board Test. | ||||

|

| the machine. |

| ||||||

|

|

|

|

|

|

|

|

| |

|

|

| 6. Perform the Power Board Test. | ||||||

|

|

| 7. The Control Board may be faulty. | ||||||

|

|

|

|

| |||||

The thermal light is lit. | The | 1. The welding application may be | 1. | One of the thermostats may be | |||||

machine regularly "overheats." | exceeding the recommended |

|

| faulty. | Also | check | associated | ||

|

| duty cycle and/or current limits |

|

| wiring for loose or faulty con- | ||||

|

| of the machine. |

|

| nections. | See the Wiring | |||

|

| 2. Dirt and dust may have clogged |

|

| Diagram. |

|

|

| |

|

|

|

|

|

|

|

|

| |

|

| the cooling channels inside the |

|

|

|

|

|

|

|

|

| machine. Refer to the Maint- |

|

|

|

|

|

|

|

|

| enance Section of this manual. |

|

|

|

|

|

|

|

|

| 3. Air intake and exhaust louvers |

|

|

|

|

|

|

|

|

| may be blocked due to inade- |

|

|

|

|

|

|

|

|

| quate clearance around the |

|

|

|

|

|

|

|

|

| machine. |

|

|

|

|

|

|

|

|

| 4. Make sure the fan is functioning |

|

|

|

|

|

|

|

|

| correctly. Machines above code |

|

|

|

|

|

|

|

|

| 10500 are equipped with F.A.N. |

|

|

|

|

|

|

|

|

| (fan as needed) circuitry. The |

|

|

|

|

|

|

|

|

| fan runs whenever the output is |

|

|

|

|

|

|

|

|

| enabled, whether under load or |

|

|

|

|

|

|

|

|

| open circuit conditions. The fan |

|

|

|

|

|

|

|

|

| also runs for a period of time |

|

|

|

|

|

|

|

|

| (approximately 5 minutes) after |

|

|

|

|

|

|

|

|

| the output is disabled. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call