INSTALLATION

Return to Section TOC

TOC

WORK VOLTAGE SENSING

The Power Wave is shipped from the factory with the work sense lead enabled.

For processes requiring work voltage sensing, connect the (21) work voltage sense lead from the Power Wave to the work. Attach the sense lead to the work as close to the weld as practical. To enable the work voltage sensing in the Power Wave, refer to the section DIP

SWITCH SETTINGS AND LOCATIONS.

ELECTRODE VOLTAGE SENSING

Enabling or disabling electrode voltage sensing is auto- matically configured through software. Electrode sense lead 67 must be connected at the wire feeder.

CONTROL CABLE SPECIFICATIONS

It is recommended that genuine Lincoln control cables be used at all times. Lincoln cables are specifically designed for the communication and power needs of the Power Wave / Power Feed system.

CAUTION

The use of

Lincoln control cables are copper 22 conductor cable in a

Return to Section

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

POWER WAVE / POWER FEED WIRE FEEDER INTERCONNECTIONS

Connect the control cable between the power source and wire feeder. The wire feeder connection on the robotic Power Wave is located under the spring loaded output cover, near the bottom of the case front. The control cable is keyed and polarized to prevent improp- er connection.

For convenience sake, the electrode and control cables can be routed behind the left or right strain reliefs (under the spring loaded output cover), and along the channels formed into the base of the Power Wave, out the back of the channels, and then to the wire feeder.

Output connections on some Power Waves are made via

A work lead must be run from the negative

CAUTION

Excessive voltage drops at the work piece connection often result in unsatisfactory pulse welding perfor- mance.

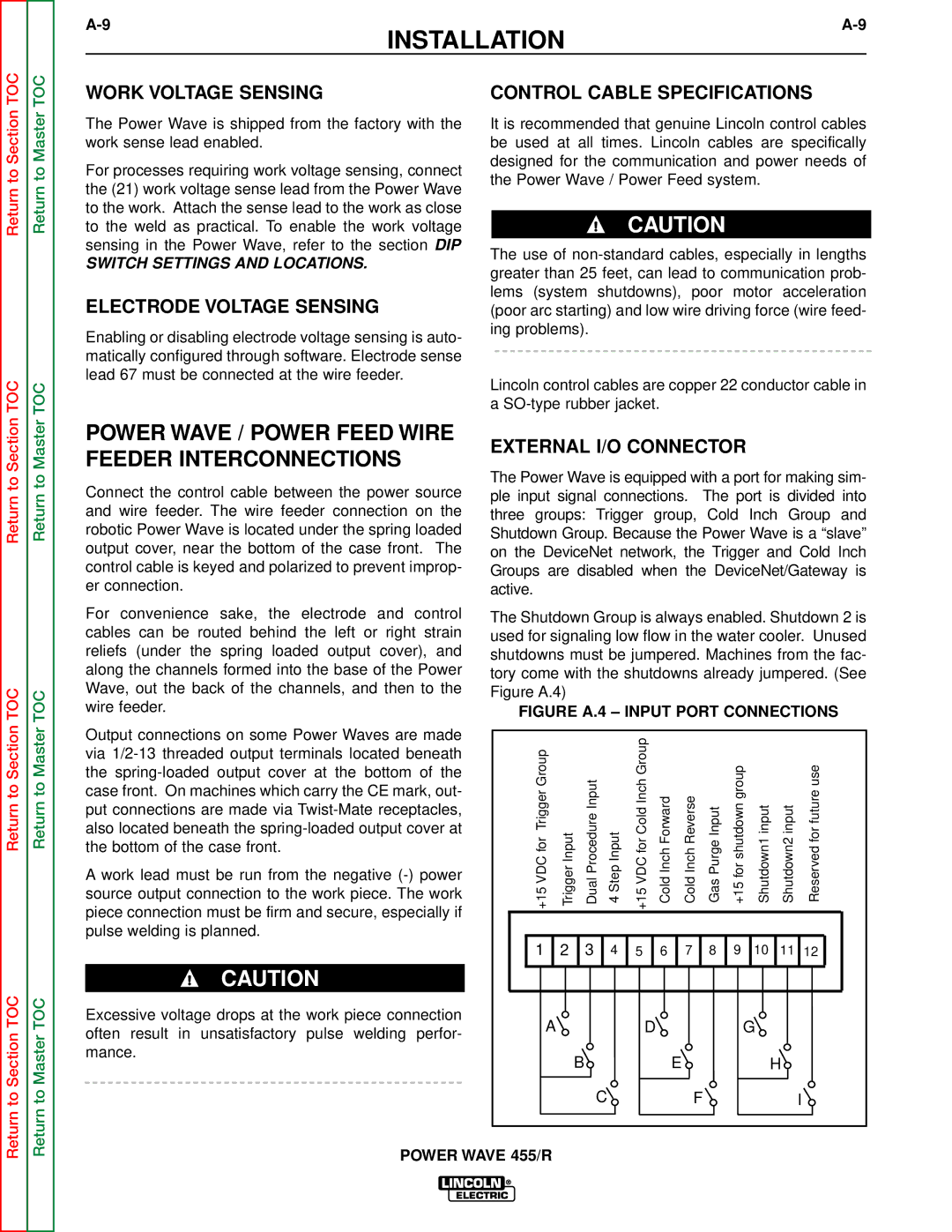

EXTERNAL I/O CONNECTOR

The Power Wave is equipped with a port for making sim- ple input signal connections. The port is divided into three groups: Trigger group, Cold Inch Group and Shutdown Group. Because the Power Wave is a “slave” on the DeviceNet network, the Trigger and Cold Inch Groups are disabled when the DeviceNet/Gateway is active.

The Shutdown Group is always enabled. Shutdown 2 is used for signaling low flow in the water cooler. Unused shutdowns must be jumpered. Machines from the fac- tory come with the shutdowns already jumpered. (See Figure A.4)

FIGURE A.4 – INPUT PORT CONNECTIONS

+15 VDC for Trigger Group | Trigger Input | Dual Procedure Input | 4 Step Input | +15 VDC for Cold Inch Group | Cold Inch Forward | Cold Inch Reverse | Gas Purge Input | +15 for shutdown group | Shutdown1 input | Shutdown2 input | Reserved for future use |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| A |

|

|

| D |

|

|

| G |

|

|

|

| B |

|

|

| E |

|

|

| H |

|

|

|

| C |

|

|

| F |

|

|

| I |

POWER WAVE 455/R