Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

OPERATION | ||

STT WELDING |

|

|

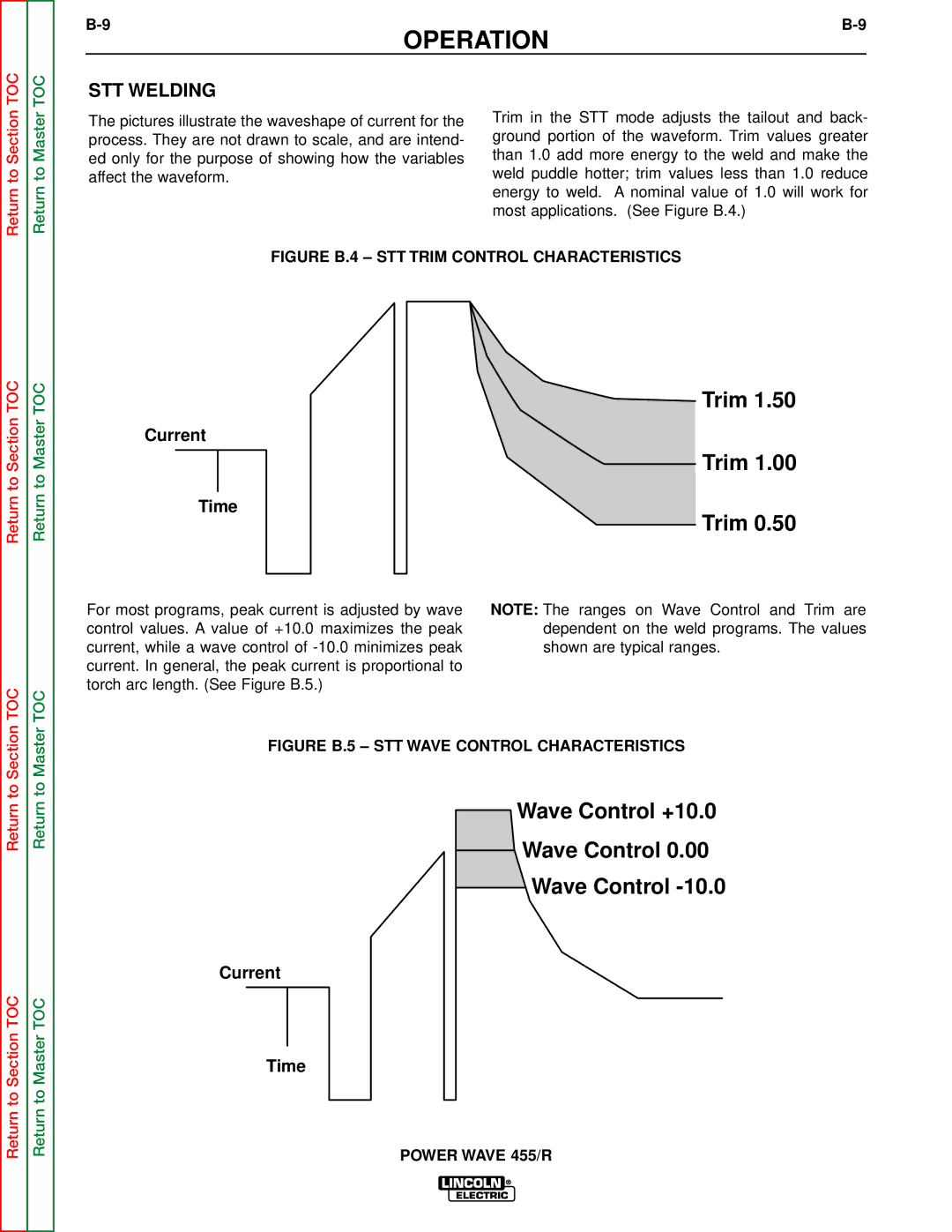

The pictures illustrate the waveshape of current for the | Trim in the STT mode adjusts the tailout and back- | |

process. They are not drawn to scale, and are intend- | ground portion of the waveform. Trim values greater | |

ed only for the purpose of showing how the variables | than 1.0 add more energy to the weld and make the | |

affect the waveform. | weld puddle hotter; trim values less than 1.0 reduce | |

| energy to weld. A nominal value of 1.0 will work for | |

most applications. (See Figure B.4.)

FIGURE B.4 – STT TRIM CONTROL CHARACTERISTICS

Trim 1.50

Current

Trim 1.00

Time

Trim 0.50

For most programs, peak current is adjusted by wave | NOTE: The ranges on Wave Control and Trim are |

control values. A value of +10.0 maximizes the peak | dependent on the weld programs. The values |

current, while a wave control of | shown are typical ranges. |

current. In general, the peak current is proportional to |

|

torch arc length. (See Figure B.5.) |

|

FIGURE B.5 – STT WAVE CONTROL CHARACTERISTICS

Wave Control +10.0

Wave Control 0.00

Wave Control