Section TOC

Master TOC

TROUBLESHOOTING & REPAIR

INPUT RECTIFIER TEST (CONTINUED)

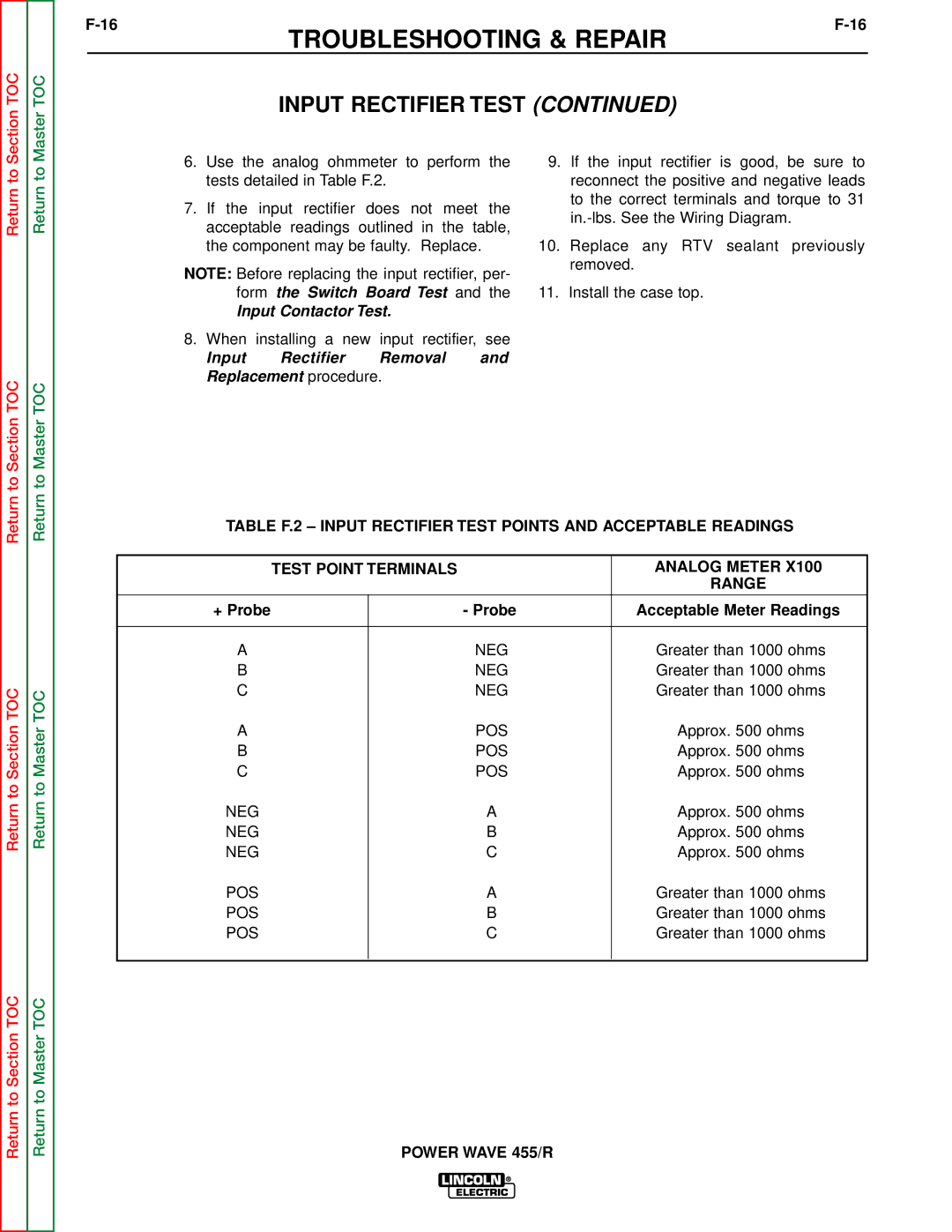

6.Use the analog ohmmeter to perform the tests detailed in Table F.2.

7.If the input rectifier does not meet the acceptable readings outlined in the table, the component may be faulty. Replace.

NOTE: Before replacing the input rectifier, per- form the Switch Board Test and the

Input Contactor Test.

8.When installing a new input rectifier, see

Input Rectifier Removal and Replacement procedure.

9.If the input rectifier is good, be sure to reconnect the positive and negative leads to the correct terminals and torque to 31

10.Replace any RTV sealant previously removed.

11.Install the case top.

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

TABLE F.2 – INPUT RECTIFIER TEST POINTS AND ACCEPTABLE READINGS

TEST POINT TERMINALS |

| ANALOG METER X100 | |

|

|

| RANGE |

|

|

|

|

+ Probe |

| - Probe | Acceptable Meter Readings |

|

|

|

|

A |

| NEG | Greater than 1000 ohms |

B |

| NEG | Greater than 1000 ohms |

C |

| NEG | Greater than 1000 ohms |

A |

| POS | Approx. 500 ohms |

B |

| POS | Approx. 500 ohms |

C |

| POS | Approx. 500 ohms |

NEG |

| A | Approx. 500 ohms |

NEG |

| B | Approx. 500 ohms |

NEG |

| C | Approx. 500 ohms |

POS |

| A | Greater than 1000 ohms |

POS |

| B | Greater than 1000 ohms |

POS |

| C | Greater than 1000 ohms |

|

|

|

|