Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

|

|

|

| |||

TROUBLESHOOTING & REPAIR |

|

|

|

| ||

Observe Safety Guidelines |

| TROUBLESHOOTING GUIDE | ||||

detailed in the beginning of this manual. |

|

|

|

|

| |

|

|

|

|

| ||

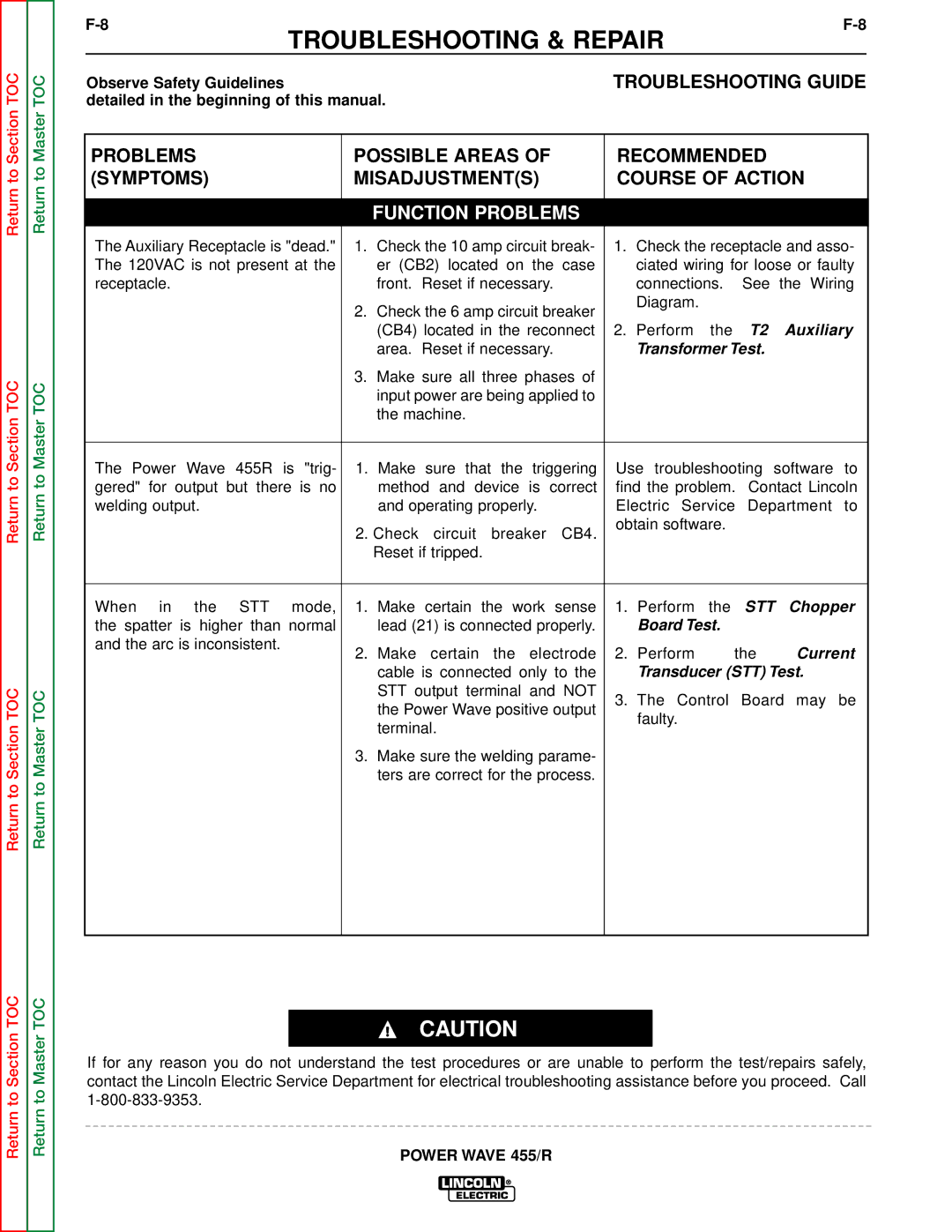

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

|

| ||

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | ||||

|

|

|

|

|

|

|

| FUNCTION PROBLEMS |

|

|

|

|

|

The Auxiliary Receptacle is "dead." | 1. Check the 10 amp circuit break- | 1. Check the receptacle and asso- | ||||

The 120VAC is not present at the | er (CB2) located on the case | ciated wiring for loose or faulty | ||||

receptacle. | front. Reset if necessary. | connections. |

| See | the Wiring | |

| 2. Check the 6 amp circuit breaker | Diagram. |

|

|

|

|

|

|

|

|

|

| |

| (CB4) located in the reconnect | 2. Perform the T2 Auxiliary | ||||

| area. Reset if necessary. | Transformer Test. |

|

| ||

| 3. Make sure all three phases of |

|

|

|

|

|

| input power are being applied to |

|

|

|

|

|

| the machine. |

|

|

|

|

|

|

|

|

|

| ||

The Power Wave 455R is "trig- | 1. Make sure that the triggering | Use troubleshooting | software to | |||

gered" for output but there is no | method and device is correct | find the problem. | Contact Lincoln | |||

welding output. | and operating properly. | Electric Service | Department to | |||

| 2. Check circuit breaker CB4. | obtain software. |

|

|

|

|

|

|

|

|

|

| |

| Reset if tripped. |

|

|

|

|

|

|

|

|

| |||

When in the STT mode, | 1. Make certain the work sense | 1. Perform the STT Chopper | ||||

the spatter is higher than normal | lead (21) is connected properly. | Board Test. |

|

|

|

|

and the arc is inconsistent. | 2. Make certain the electrode | 2. Perform | the | Current | ||

| ||||||

| cable is connected only to the | Transducer (STT) Test. | ||||

| STT output terminal and NOT | 3. The Control |

| Board may be | ||

| the Power Wave positive output |

| ||||

| faulty. |

|

|

|

| |

| terminal. |

|

|

|

| |

|

|

|

|

|

| |

| 3. Make sure the welding parame- |

|

|

|

|

|

| ters are correct for the process. |

|

|

|

|

|

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call