Return to Section TOC

Return to Section TOC

to Section TOC

Return to Master TOC

Return to Master TOC

to Master TOC

|

|

| THEORY OF OPERATION |

|

|

|

| |||||||

|

|

|

|

|

|

|

|

| ||||||

|

|

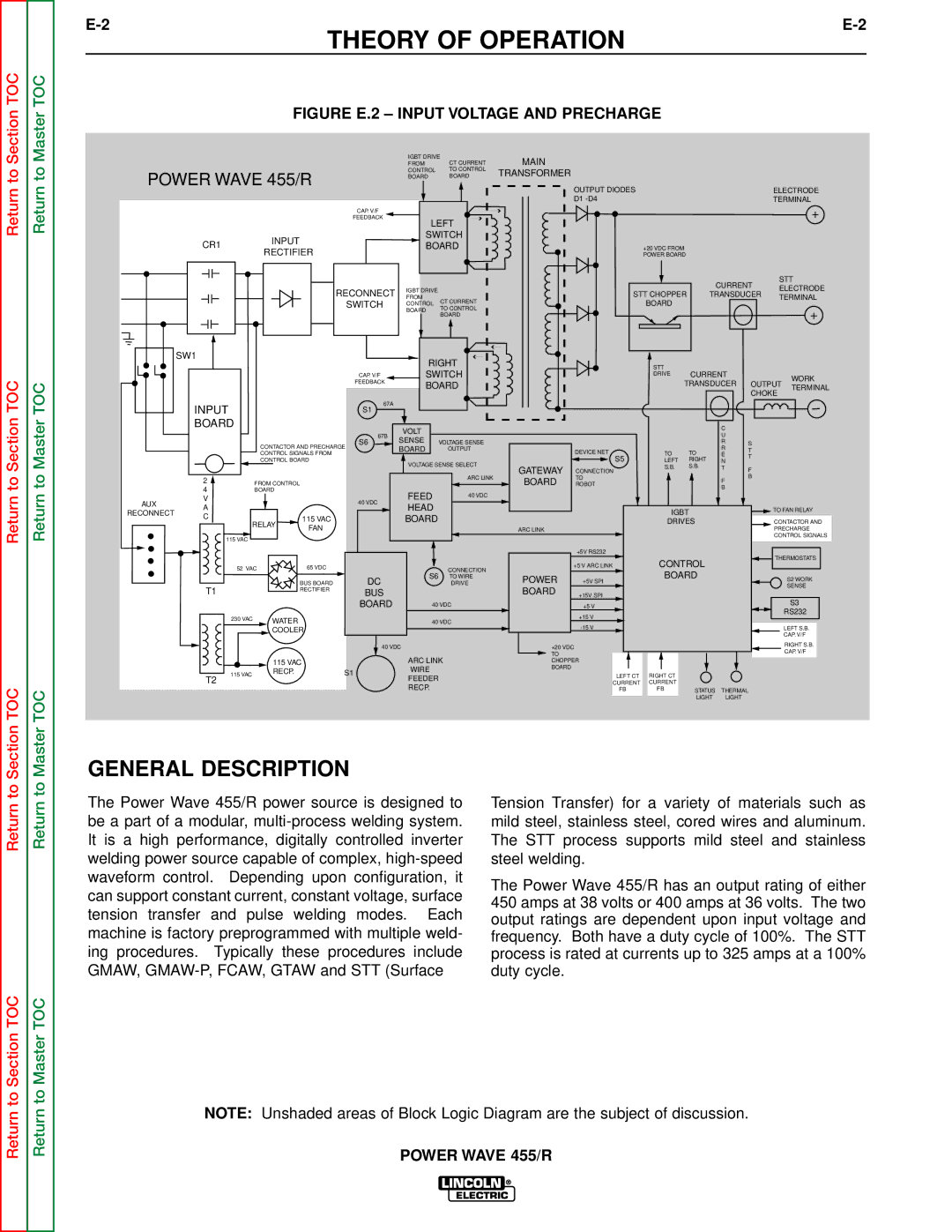

| FIGURE E.2 – INPUT VOLTAGE AND PRECHARGE |

|

|

|

| |||||||

|

|

|

|

|

| IGBT DRIVE | MAIN |

|

|

|

|

|

| |

|

|

|

|

|

| FROM | CT CURRENT |

|

|

|

|

|

| |

POWER WAVE 455/R |

| CONTROL | TO CONTROL | TRANSFORMER |

|

|

|

|

|

| ||||

| BOARD | BOARD |

|

|

|

|

|

| ||||||

|

|

|

| OUTPUT DIODES |

|

|

|

| ELECTRODE | |||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| D1 |

|

|

|

| TERMINAL |

|

|

|

|

| CAP. V/F |

|

|

|

|

|

|

|

| + |

|

|

|

|

| FEEDBACK | LEFT |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| CR1 |

| INPUT |

|

| SWITCH |

|

|

|

|

|

|

| |

|

|

|

| BOARD |

|

| +20 VDC FROM |

|

|

|

| |||

|

| RECTIFIER |

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

| POWER BOARD |

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

| CURRENT | STT | |

|

|

|

|

| RECONNECT | IGBT DRIVE |

|

|

|

|

| ELECTRODE | ||

|

|

|

|

|

|

| STT CHOPPER | TRANSDUCER | ||||||

|

|

|

|

| FROM |

|

| TERMINAL | ||||||

|

|

|

|

| SWITCH | CT CURRENT |

|

| BOARD |

|

|

| ||

|

|

|

|

| CONTROL |

|

|

|

|

|

| |||

|

|

|

|

| TO CONTROL |

|

|

|

|

|

| |||

|

|

|

|

|

| BOARD |

|

|

|

|

|

| + | |

|

|

|

|

|

|

| BOARD |

|

|

|

|

|

| |

| SW1 |

|

|

|

| RIGHT |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| STT |

|

|

|

| ||

|

|

|

|

| CAP. V/F | SWITCH |

|

| DRIVE | CURRENT |

| WORK | ||

|

|

|

|

| FEEDBACK |

|

|

|

| TRANSDUCER |

| |||

|

|

|

|

| BOARD |

|

| OUTPUT TERMINAL | ||||||

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

| CHOKE | |

| INPUT |

|

|

| 67A |

|

|

|

|

|

|

|

|

|

|

|

|

| S1 |

|

|

|

|

|

|

|

|

| |

| BOARD |

|

|

|

| VOLT |

|

|

|

|

| C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

| 67B |

|

|

|

|

| U |

|

| |

|

|

|

|

| SENSE |

|

|

|

|

|

|

| ||

|

|

|

|

| S6 | VOLTAGE SENSE |

|

|

|

| R | S |

| |

|

|

| CONTACTOR AND PRECHARGE | BOARD | OUTPUT |

| DEVICE NET | TO | TO | R | T |

| ||

|

|

| CONTROL SIGNALS FROM |

|

|

|

| E | T |

| ||||

|

|

| CONTROL BOARD |

|

|

|

| S5 | LEFT | RIGHT | N |

| ||

|

|

|

| VOLTAGE SENSE SELECT |

|

|

| |||||||

|

|

|

|

|

| GATEWAY | CONNECTION | S.B. | S.B. | T | F |

| ||

|

|

|

|

|

|

|

|

|

|

|

| |||

| 2 | FROM CONTROL |

|

|

| ARC LINK | BOARD | TO |

|

| F | B |

| |

|

|

|

|

| ROBOT |

|

|

|

| |||||

| 4 | BOARD |

|

| FEED | 40 VDC |

|

|

|

| B |

|

| |

| V |

|

|

|

|

|

|

|

|

|

|

| ||

AUX | A |

|

|

| 40 VDC | HEAD |

|

|

| IGBT |

|

|

| TO FAN RELAY |

RECONNECT |

|

|

|

|

|

|

|

|

|

| ||||

C |

|

| 115 VAC |

| BOARD |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| DRIVES |

|

| CONTACTOR AND | ||||

| RELAY |

|

|

|

|

|

| |||||||

| FAN |

|

|

| ARC LINK |

|

|

|

|

| PRECHARGE | |||

|

|

|

|

|

|

|

|

|

|

|

| |||

| 115 VAC |

|

|

|

|

|

|

|

|

|

|

|

| CONTROL SIGNALS |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| +5V RS232 |

|

|

|

| THERMOSTATS |

|

|

|

|

|

|

|

|

|

| CONTROL |

|

| ||

| 52 VAC |

| 65 VDC |

|

| CONNECTION |

| +5 V ARC LINK |

|

|

| |||

|

|

|

| S6 |

|

| BOARD |

|

|

| ||||

|

|

|

| BUS BOARD | DC | TO WIRE | POWER | +5V SPI |

|

| S2 WORK | |||

|

|

|

|

| DRIVE |

|

|

|

| |||||

| T1 |

|

| RECTIFIER | BUS |

|

| BOARD | +15V SPI |

|

|

|

| SENSE |

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

| BOARD | 40 VDC |

| +5 V |

|

|

|

| S3 | |

|

|

|

|

|

|

|

|

| +15 V |

|

|

|

| RS232 |

| 230 VAC |

| WATER |

|

| 40 VDC |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| LEFT S.B. | |||||

|

|

| COOLER |

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

| CAP. V/F |

|

|

|

|

| 40 VDC |

| +20 VDC |

|

|

|

| RIGHT S.B. | ||

|

|

|

|

|

|

|

|

|

| CAP. V/F | ||||

|

|

|

|

|

|

|

| TO |

|

|

|

|

| |

|

|

|

|

|

| ARC LINK |

|

|

|

|

|

| ||

|

|

| 115 VAC |

| CHOPPER |

|

|

|

|

| ||||

|

|

| RECP. |

| S1 | WIRE |

| BOARD |

|

|

|

|

|

|

| 115 VAC |

|

|

|

| LEFT CT | RIGHT CT |

|

|

|

| |||

|

|

| FEEDER |

|

|

|

|

|

| |||||

| T2 |

|

|

|

|

|

| CURRENT | CURRENT |

|

|

|

| |

|

|

|

|

|

| RECP. |

|

| FB | FB | STATUS | THERMAL |

| |

|

|

|

|

|

|

|

|

|

|

| LIGHT | LIGHT |

|

|

GENERAL DESCRIPTION

Return

Return

The Power Wave 455/R power source is designed to be a part of a modular,

Tension Transfer) for a variety of materials such as mild steel, stainless steel, cored wires and aluminum. The STT process supports mild steel and stainless steel welding.

The Power Wave 455/R has an output rating of either 450 amps at 38 volts or 400 amps at 36 volts. The two output ratings are dependent upon input voltage and frequency. Both have a duty cycle of 100%. The STT process is rated at currents up to 325 amps at a 100% duty cycle.

Return to Section TOC

Return to Master TOC

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.