OPERATION

Return to Section TOC

WELDING MODE DESCRIPTIONS

CONSTANT VOLTAGE WELDING

For each wire feed speed, a corresponding voltage is preprogrammed into the machine through special soft- ware at the factory. The preprogrammed voltage is the best average voltage for a given wire feed speed. With synergic programs, when the wire feed speed changes, the Power Wave will automatically adjust the corre- sponding voltage.

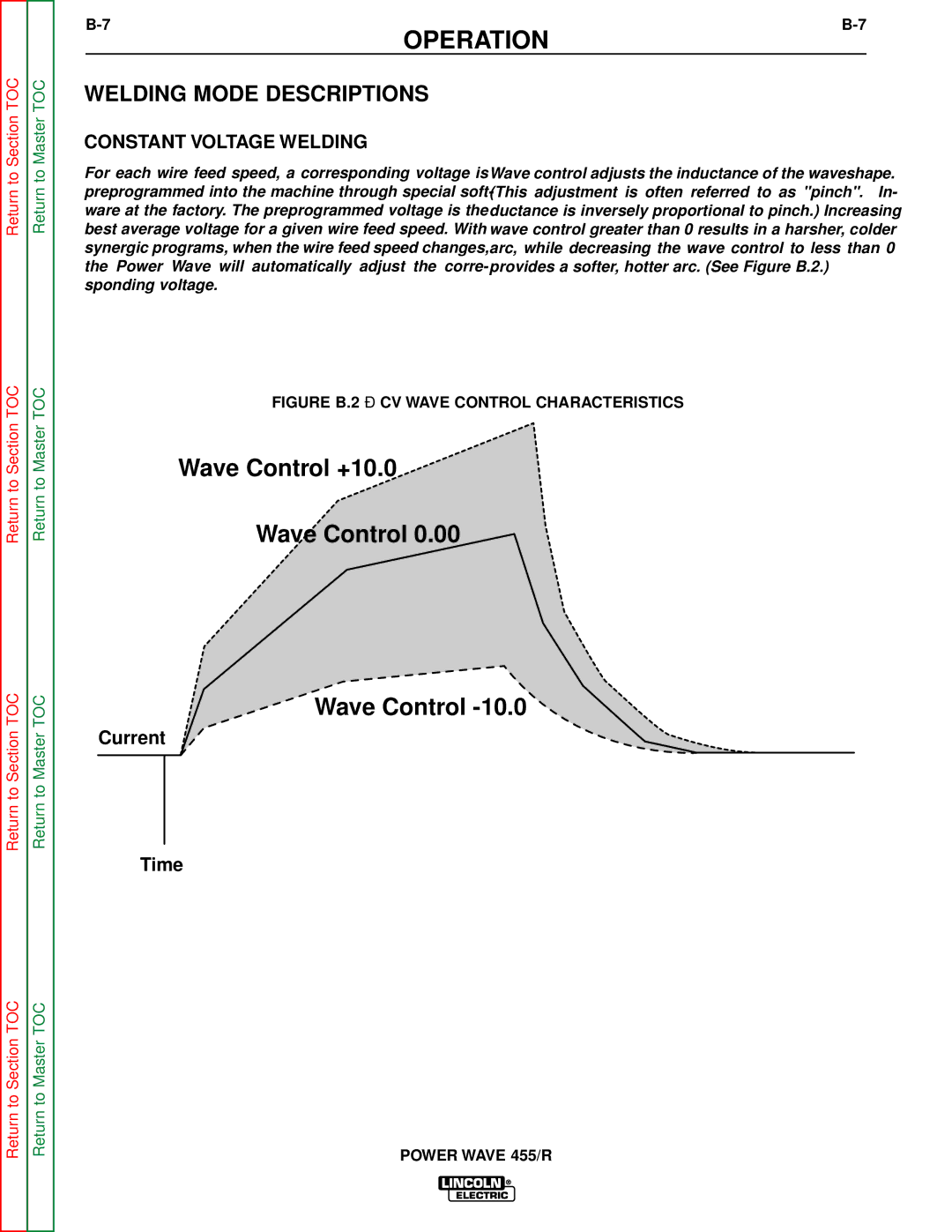

Wave control adjusts the inductance of the waveshape. (This adjustment is often referred to as "pinch". In- ductance is inversely proportional to pinch.) Increasing wave control greater than 0 results in a harsher, colder arc, while decreasing the wave control to less than 0 provides a softer, hotter arc. (See Figure B.2.)

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

FIGURE B.2 – CV WAVE CONTROL CHARACTERISTICS

Wave Control +10.0

Wave Control 0.00

Wave Control

Current

Time