Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

11 ROUTINE MAINTENANCE

NOTE

The operations outlined in this chapter are to be performed by qualified maintenance personnel only.

11.1 Model 300M Maintenance Schedule

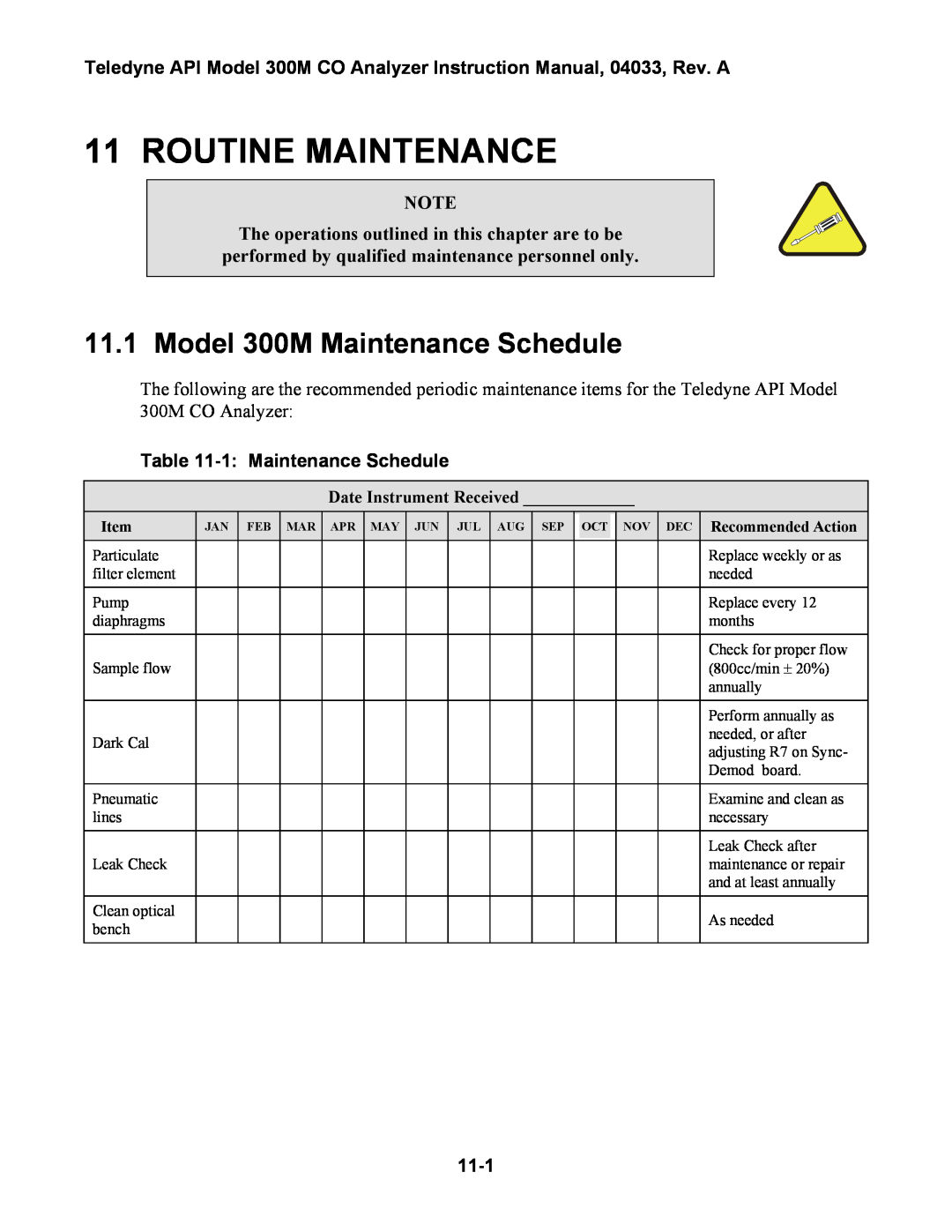

The following are the recommended periodic maintenance items for the Teledyne API Model

300M CO Analyzer:

Table 11-1: Maintenance Schedule

|

|

|

| Date Instrument Received _____________ | |||||||||||

Item | JAN | FEB | MAR | APR | MAY | JUN | JUL | AUG | SEP |

| OCT |

| NOV | DEC | Recommended Action |

Particulate |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Replace weekly or as |

filter element |

|

|

|

|

|

|

|

|

|

|

|

|

|

| needed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pump |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Replace every 12 |

diaphragms |

|

|

|

|

|

|

|

|

|

|

|

|

|

| months |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sample flow |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Check for proper flow |

|

|

|

|

|

|

|

|

|

|

|

|

|

| (800cc/min ± 20%) | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| annually |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Perform annually as |

Dark Cal |

|

|

|

|

|

|

|

|

|

|

|

|

|

| needed, or after |

|

|

|

|

|

|

|

|

|

|

|

|

|

| adjusting R7 on Sync- | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Demod board. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pneumatic |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Examine and clean as |

lines |

|

|

|

|

|

|

|

|

|

|

|

|

|

| necessary |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Leak Check after |

Leak Check |

|

|

|

|

|

|

|

|

|

|

|

|

|

| maintenance or repair |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| and at least annually |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clean optical |

|

|

|

|

|

|

|

|

|

|

|

|

|

| As needed |

bench |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|