E6581090

14.2Periodical inspection

Make a periodical inspection at intervals of 3 or 6 months depending on the operating conditions.

![]() Warning

Warning

•Before inspection, perform the following steps.

| ①Shut off all input power to the inverter. |

Mandatory | ②Wait for at least 15 minutes and check that the charge lamp is no longer lit. |

| ③Use a tester that can measure DC voltages (800V DC or more), and check that the |

| voltage to the DC main circuits (across |

| Performing an inspection without carrying out these steps first could lead to electric shock. |

•Never replace any part.

This could be a cause of electric shock, fire or bodily injury. To replace parts, call the

Prohibited | local sales agency. |

|

■Check items

1.Check to see if all screwed terminals are tightened firmly. If any screw is found loose, tighten it again with a screwdriver.

2.Check to see if all crimped terminals are fixed properly. Check them visually to see that there is no trace of overheating around any of them.

3.Check visually all cables and wires for damage.

4.With a vacuum cleaner, remove dirt and dust, especially from the vents and the printed circuit boards. Always keep them clean to prevent an accident due to dirt or dust.

5.When leaving the inverter unused for a long time, check it for functioning once every 2 years or so by supplying it with electricity for at least 5 hours with the motor disconnected. It is advisable not to supply the commercial power directly to the inverter but to gradually increase the power supply voltage with a transformer.

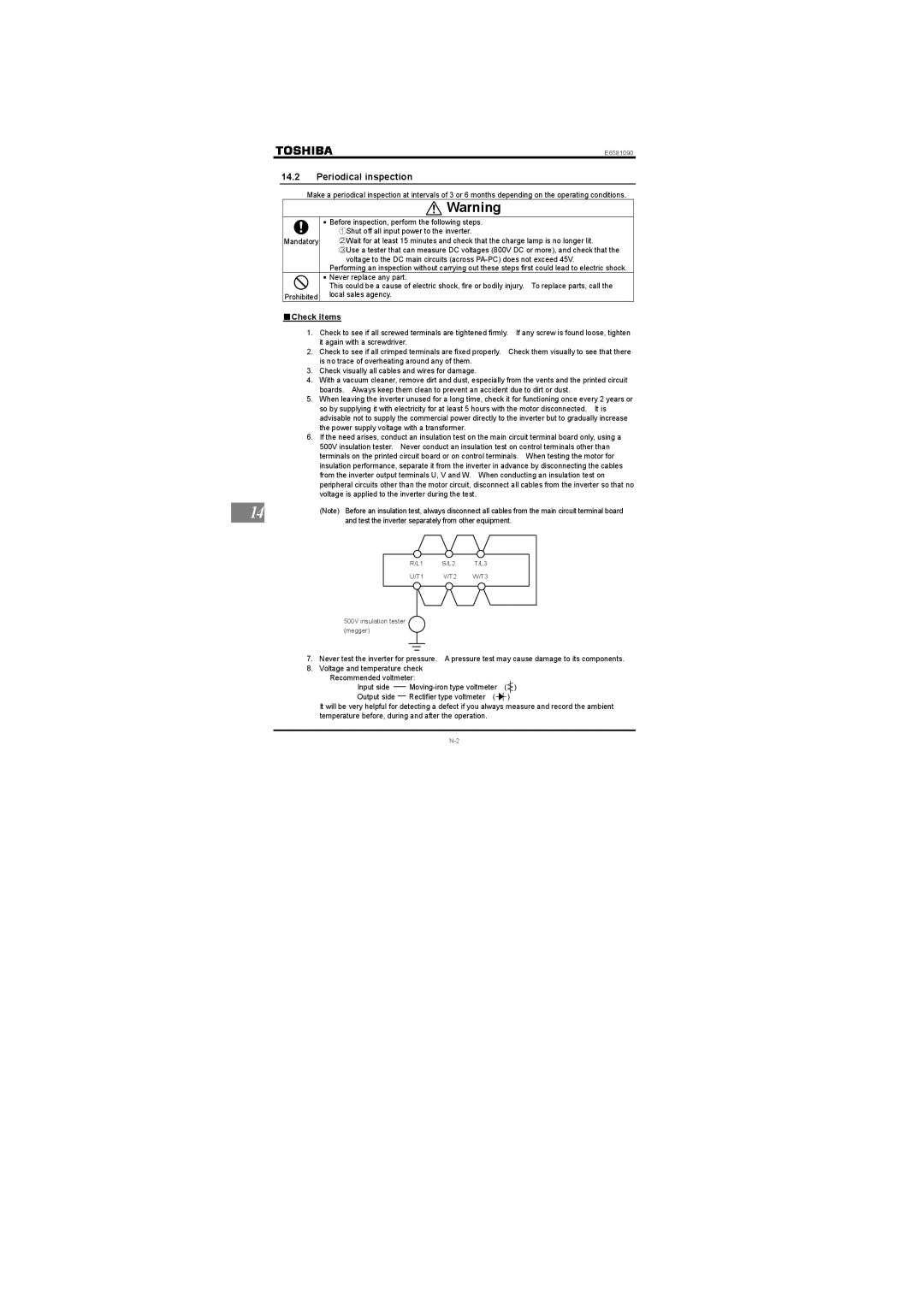

6.If the need arises, conduct an insulation test on the main circuit terminal board only, using a 500V insulation tester. Never conduct an insulation test on control terminals other than terminals on the printed circuit board or on control terminals. When testing the motor for insulation performance, separate it from the inverter in advance by disconnecting the cables from the inverter output terminals U, V and W. When conducting an insulation test on peripheral circuits other than the motor circuit, disconnect all cables from the inverter so that no voltage is applied to the inverter during the test.

14 | (Note) | Before an insulation test, always disconnect all cables from the main circuit terminal board |

| and test the inverter separately from other equipment. | |

|

|

R/L1 S/L2 T/L3

U/T1 V/T2 W/T3

500V insulation tester (megger)

7.Never test the inverter for pressure. A pressure test may cause damage to its components.

8.Voltage and temperature check

Recommended voltmeter: |

|

| ||

Input side ___ | ( ) | |||

Output side __ | Rectifier type voltmeter ( |

|

| ) |

It will be very helpful for detecting a defect if you always measure and record the ambient temperature before, during and after the operation.