WR450FR

Page

By Yamaha Motor Corporation, U.S.A 1st Edition, October

WR450FR

LIT-11626-16-43

Introduction

Page

Always Maintain Your Machine in Proper Working Order

Always Wear Protective Apparel

Park the Machine Carefully Turn OFF the Engine

Gasoline can Cause Injury

Properly Secure the Machine Before Transporting IT

Weights of machines without fuel

M. Machine Weights

Finding the Required

Particularly Important Information

Manual Format

HOW to Read Descriptions

GEN Spec Info Insp ENG ADJ

Memo

Index

Chapter Regular Inspection Adjustments

Front Wheel and Rear Wheel Front Brake and Rear Brake

SEAT, Fuel Tank Side Covers

TPS Throttle Position Sensor

Electrical Components

Description

Description Info

Model Label

Machine Identification

Vehicle Identification Number

Engine Serial Number

Important Information

Preparation for Removal and Disassembly

Bearings and OIL Seals

ALL Replacement Parts

Lock WASHERS/PLATES and Cotter Pins

GASKETS, OIL Seals and O-RINGS

Circlips

Checking of Connection

Special Tools

Part number Tool name/How to use Illustration

GEN Info

ACC-QUICK-GS-KT

Control Functions

Main Switch

Main switch indicator light

Start Switch

Throttle Grip

Clutch Lever

Shift Pedal

Kickstarter

HOT Starter Lever

Rear Brake Pedal

Fuel Cock

Cold Starter Knob

Nipple Wrench

Lights Switch

Valve Joint

Spark Plug Wrench

Fuel

Starting and BREAK-IN

AIR Filter Maintenance

Starting a Cold Engine

Do not warm up the engine for extended periods of time

Restarting an engine after a fall

Starting a Warm Engine

Engine fails to start

PISTON, RING, VALVES, Camshafts and Gears

BREAK-IN Procedures

Cylinder and Crankshaft

About one hour of break-in operation is necessary

TORQUE-CHECK Points

Cleaning

Cleaning and Storage

Storage

5TJ4 CDN, AUS, NZ, ZA

General Specifications

FCR MX39

CDI

Engine

Maintenance Specifications

Seat Width

7083 ~ 0.7087 7075

Spec

USA CDN, AUS, NZ

Spec

Standard Lubrication chart

Part to be tightened Thread size ’ty Tightening torque

Oil strainer frame

USA, CDN Europe AUS, NZ, ZA

Chassis

DID520VM/DAIDO

Handle crown and outer tube

Rear wheel axle and nut

M4 ⋅

5TA-00/DENSO

Electrical

ACM33221 M06/MATSUSHITA

Mkg Ftlb 10 mm 12 mm 14 mm 17 mm 19 mm 22 mm 16 mm 130

General Torque Specifications

Definition of Units

Torque

Lubrication Diagrams

Spec

Cable Routing Diagram

Spec

Spec

Spec

Spec

Spec

Insp ADJ

Maintenance Intervals

Shift FORK, Shift CAM, Guide BAR

Marked For USA

General Inspection and Maintenance

PRE-OPERATION Inspection and Maintenance

Coolant Level Inspection

Coolant Replacement

Do not remove the radiator cap when the engine is hot

Engine

Coolant Replacement

Fill Radiator Engine To specified level

Radiator CAP Opening Pressure Inspection

Radiator CAP Inspection

Radiator cap opening pressure 110 kPa 1.1 kg/cm2, 15.6 psi

Cooling System Inspection

Cooling System Inspection

Standard pressure KPa 1.8 kg/cm2, 25.6 psi

Throttle Cable Adjustment

Clutch Adjustment

Hot starter lever free play a 3 ~ 6 mm 0.12 ~ 0.24

HOT Starter Lever Adjustment

Hot starter lever free play adjustment steps

Throttle Lubrication

AIR Filter Cleaning

AIR Filter Cleaning

Insp ADJ

Engine OIL Level Inspection

Engine OIL Level Inspection

API Standard

When the oil tank is empty, never start the engine

Recommended oil

Recommended engine oil classi- fication

Engine OIL Replacement

Engine OIL Replacement

Oil filter cover 10 Nm 1.0 m kg, 7.2 ft lb

Replacement steps

Pilot Screw Adjustment

Pilot Screw Adjustment

Adjustment steps

Idle Speed Adjustment

Valve Clearance Adjustment

Valve Clearance Adjustment

Mm increments

Pad range Pad Availability Increments 20 mm

40 mm

Example

Last digit of pad Rounded value

Bolt camshaft cap 10 Nm 1.0 m kg, 7.2 ft lb

Insp ADJ

Exhaust

Intake

Spark Arrester Cleaning For USA

Chassis

CHASSIS/BRAKE System AIR Bleeding

Brake System AIR Bleeding

Locknut Nm 0.5 m kg, 3.6 ft lb

Front Brake Adjustment

Front Brake Adjustment

Brake lever position adjustment steps

Front Brake PAD Inspection and Replacement

Rear Brake Adjustment

Do not reuse the drained brake fluid

Front Brake PAD Inspection and Replacement

Bleed screw Nm 0.6 m kg, 4.3 ft lb

Brake pad thickness a Standard Limit Mm 0.25 Mm 0.04

Rear Brake PAD Inspection and Replacement

Rear Brake PAD Inspection and Replacement

Pad pin plug Nm 0.3 m kg, 2.2 ft lb

Pad pin 18 Nm 1.8 m kg, 13 ft lb

Brake Fluid Level Inspection

Rear Brake PAD Insulator Inspection

Drive chain length 10 links Limit 150.1 mm 5.91

Sprockets INSPECTION/DRIVE Chain Inspection

Sprockets Inspection

Drive Chain Inspection

Drive Chain Inspection

Drive chain slack 40 ~ 50 mm 1.6 ~ 2.0

Drive Chain Slack Adjustment

Drive Chain Slack Adjustment

Drive chain slack adjustment steps

Front Fork Inspection

Front Fork OIL Seal and Dust Seal Cleaning

Axle nut 125 Nm 12.5 m kg, 90 ft lb

Locknut 16 Nm 1.6 m kg, 11 ft lb

Front Fork Internal Pressure Relieving

Front Fork Rebound Damping Force Adjustment

Standard position 10 clicks out Clicks out

Front Fork Compression Damping Force Adjustment

Rear Shock Absorber Inspection

Rear Shock Absorber Inspection

246 mm 9.69 240.5 ~ 258.5 mm

Rear Shock Absorber Spring Preload Adjustment

47 ~ 10.18

Standard position About 9 clicks out *About 10 clicks out

Rear Shock Absorber Rebound Damping Force Adjustment

Standard position About 6 clicks out *About 13 clicks out

Rear Shock Absorber LOW Compression Damping Force Adjustment

EC36d000

Wheel Inspection

Tire Pressure Check

Standard tire pressure KPa 1.0 kgf/cm2, 15 psi

Spokes Inspection and Tightening

Ring nut wrench YU-33975/90890-01403

Steering Head Inspection and Adjustment

Steering Head Inspection Adjustment

Steering ring nut adjustment steps

Cautio N

Lubrication

Lubrication

Spark plug gap ~ 0.8 mm 0.028 ~ 0.031

ELECTRICAL/SPARK Plug Inspection

Electrical

Spark Plug Inspection

Ignition Timing Check

Ignition Timing Check

First AID in Case of Bodily Contact External

Battery Inspection and Charging

Battery Inspection and Charging

Keep Batteries and Electrolyte OUT of Reach of Children

Measurement steps

Example

Do not quick charge a battery

Insp ADJ

Charging method using a variable voltage charger

Charging method using a constant voltage charger

Fuse Inspection

Fuse Inspection

First, connect the positive lead 1, then the negative lead

Recommended lubricant Lithium soap base grease

Items Amperage ’ty Rating

Replacing the Headlight Bulbs

Replacing the Headlight Bulbs

Adjusting the Headlight Beams

Adjusting the Headlight Beams

SEAT, Fuel Tank and Side Covers Removal

SEAT, Fuel Tank and Side Covers

Side cover

Removal Points

Exhaust Pipe Silencer Removal

Exhaust Pipe and Silencer

Exhaust pipe and silencer

Assembly and Installation Exhaust pipe and silencer

Radiator Removal

Radiator

Handling Note

Assembly and Installation Radiator

Radiator

Install Radiator breather hose Radiator right

Carburetor Removal

Carburetor

Carburetor Disassembly

Carburetor Disassembly

ENG

Carburetor

Pilot screw

Standard clip position No.4 Groove

Needle valve

Throttle valve

Jet needle

Float

Measurement and adjustment steps

Starter plunger

Accelerator pump

Assembly and Installation Carburetor

Air cut valve

ENG

ENG

Pilot screw 4 turns out example 2 turns out example

ENG

Throttle valve height Mm 0.122

Accelerator pump timing adjustment Adjustment steps

Carburetor installation

Carburetor ENG

Tighten Screw air cleaner joint

Cylinder Head Cover

Camshafts

Cylinder Head Cover Removal

Camshafts Removal

Camshaft

Runout camshaft Less than 0.03 mm 0.0012

Bolt camshaft cap 10 Nm 1.0 m kg, 7.2 ft lb

Timing chain tensioner

Assembly and Installation

Installation steps

Decompression system

Bolt camshaft cap

CA U TI on

Bolt timing chain tensioner

Camshafts ENG

Tensioner cap bolt

Cylinder Head Removal

Cylinder Head

Cylinder head

Bolts cylinder head 1st 30 Nm 3.0 m kg, 22 ft lb

Final

Bolts cylinder head

2nd

20 Nm 2.0 m kg, 14 ft lb

Valves and Valve Springs Removal

Valves and Valve Springs

Valve spring compressor YM-4019/90890-04019

Valve

ENG

Runout limit 01 mm 0.0004

Lapping steps

Valve spring

Black

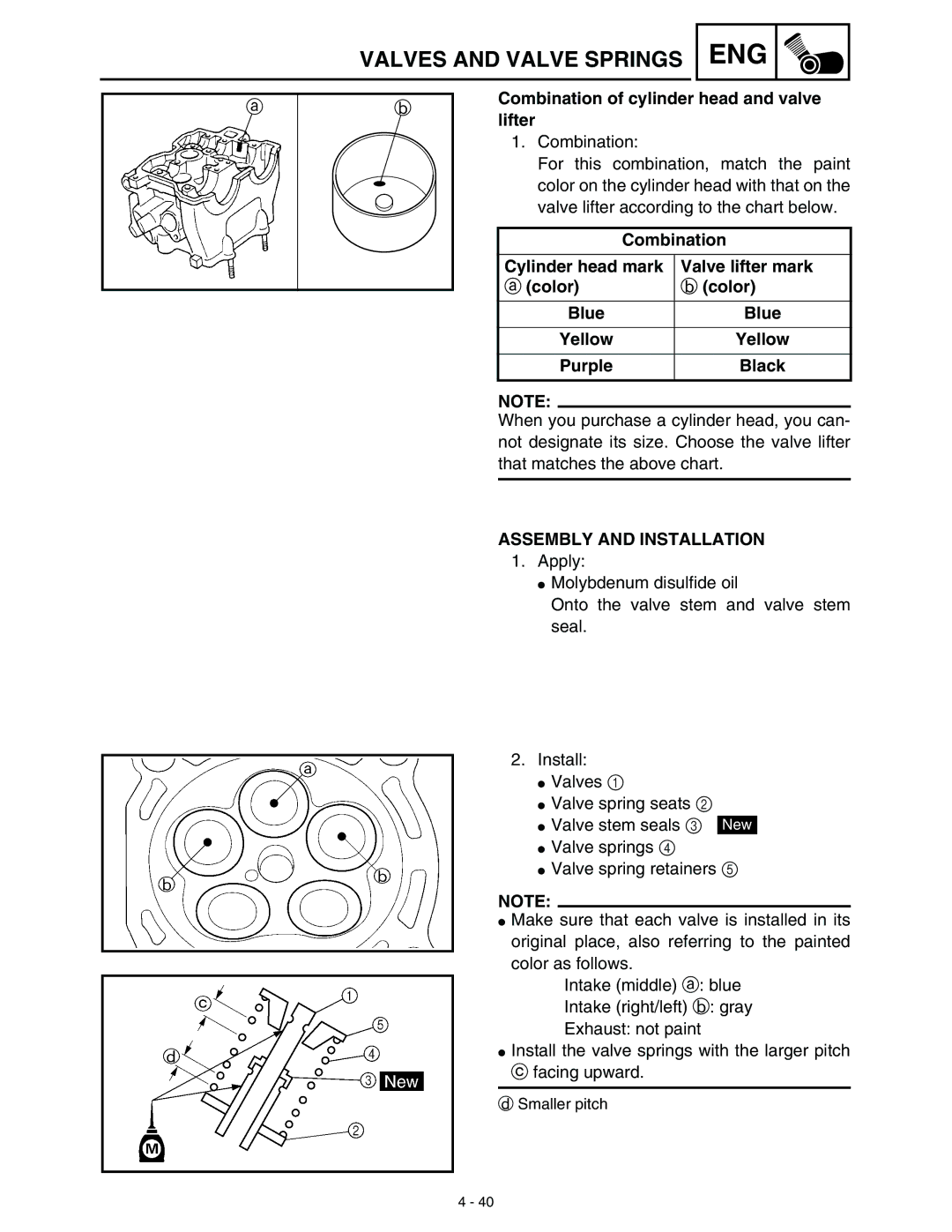

Combination of cylinder head and valve lifter

Combination Cylinder head mark Valve lifter mark Color

Yellow

CA UT ION

Cylinder and Piston Removal

Cylinder and Piston

Cylinder and piston

Piston

Piston pin puller YU-1304/90890-01304

Do not use a hammer to drive the piston pin out Piston ring

Piston size P Standard

Cylinder bore C 95.00 ~ 95.01 mm 7402 ~ 3.7406

05 mm 0.002

2nd step

End gap Standard Limit

2nd ring 020 ~ 0.055 mm 12 mm 0008 ~ 0.0022

20 ~ 0.50 mm 01 ~ 0.02

Inside diameter piston 18.004 ~ 18.015 mm 0.7088 ~ 0.7093

Piston pin

Cylinder

Clutch Removal

Clutch

ENG

Primary driven gear

Clutch housing and boss

Clutch boss

Clutch holding tool YM-91042/90890-04086

Push rod

Friction plate

Clutch plate

Warp limit Mm 0.004 Push lever

Clutch

Assembly and Installation Push lever

ENG

Install Clutch spring Bolt clutch spring

OIL FILTER, Water Pump and Crankcase Cover Right

OIL FILTER, Water Pump and Crankcase Cover Right

OIL FILTER, Water Pump Crankcase Cover Right Removal

ENG

Oil seal

Impeller shaft

Bearing

Crankcase cover right

Kick crank

Water pump housing

Oil filter

Balancer Removal

Balancer

Balancer

Balancer drive gear and balancer driven gear

Balancer, balancer drive gear and balancer driven gear

OIL Pump

OIL Pump Removal and DIS Assembly

ENG

Oil pump

Assembly and Installation Oil pump

Bolt oil pump assembly L = 25 mm 0.98

Kick Axle and Shift Shaft Removal

Kick Axle and Shift Shaft

ENG

Kick axle and ratchet wheel

Kick axle assembly

Shift guide and shift lever assembly

Segment

Shift shaft

Assembly and Installation Segment

Stopper lever

Install Torsion spring Stopper lever Bolt stopper lever

EC4C5301

Kick idle gear

AC Magneto and Stator Removal

AC Magneto and Starter Clutch

ENG

Woodruff key

Rotor

Rotor puller YM-04141/90890-04141

AC magneto

Starter clutch

Assembly and Installation AC magneto and starter clutch

Quick gasket ACC-QUICK-GS-KT Yamaha Bond No 90890-85505

Install Bolt starter clutch

Install Engine guard Clamp Bolt engine guard front

Engine Removal

Engine Removal

ENG

ENG

Engine removal

Drive sprocket

Brake pedal

Assembly and Installation Engine installation

Install Ring 1 New Dowel pin Oil hose Bolt oil hose

Crankcase Separation

Crankcase and Crankshaft

ENG

Crankcase Bearing Removal

Crankcase Bearing

Separation steps

Crankcase

Crankcase separating tool YU-1135-A/90890-01135

Crankshaft

Timing chain and timing chain guide

Oil delivery pipe

Assembly and Installation Crankshaft bearing

Quick gasket ACC-QUICK-GS-KT Yamaha Bond No

Do not use a hammer to drive in the crank- shaft

Bolt crankcase

TRANSMISSION, Shift CAM and Shift Fork

TRANSMISSION, Shift CAM and Shift Fork

TRANSMISSION, Shift CAM Shift Fork Removal

Gears

Shift fork, shaft cam and transmission

Shift fork, shift cam and segment

Assembly and Installation Transmission

ENG

ENG

Front Wheel Removal

Front Wheel and Rear Wheel Chas

Front Wheel and Rear Wheel

Front Wheel

Rear Wheel Removal

Rear Wheel

Wheel bearing if necessary

Rear wheel

Wheel

Brake disc

Wheel axle

Wheel axle bending limit 0.5 mm 0.020

Do not attempt to straighten a bent axle

Front wheel

Caacuhtutionng

105 Nm 10.5 m · kg, 75 ft · lb

Tighten Bolt axle holder

Tighten the nuts in stage, using a crisscross pattern

Front Wheel and Rear Wheel Chas

Adjust Drive chain slack a

Front Brake Removal

Front Brake and Rear Brake Chas

Front Brake and Rear Brake

Front Brake

Rear Brake Removal

Rear Brake

Caliper Disassembly

Caliper Disassembly

Master Cylinder Disas Sembly

Master Cylinder Disassembly

Caliper piston

Brake fluid

Master cylinder

Piston seal kit

Use only new brake fluid

Brake hose

Caliper

Front caliper

Always use new piston seals and dust seals

Rear caliper

Always use new copper washers

Master cylinder kit

Front master cylinder

Rear master cylinder

Caauchtutionng

Front brake hose

Cauachttuniong

Install Brake hose holder Screw brake hose holder

Rear Diaphragm Master cylinder cap Bolt master cylinder cap

Front Fork

Front Fork Chas

Front Fork Removal

Front Fork Disassembly

Front Fork Disassembly

Cap bolt

Damper rod

Inner tube

Take care not to scratch the inner tube

Oil seal removal steps

Outer tube

Base valve

Fork spring

Inner tube bending limit 0.2 mm 0.008

Assembly and Installation Front fork assembly

Front Fork Chas

Fork seal driver YM-01442/90890-01442

Recommended oil Suspension oil

Front Fork Chas

Front Fork Chas

Front fork top end standard a Zero mm Zero

Installation

Tighten Pinch bolt handle crown

Handlebar

Handlebar Chas

Handlebar Removal

Handlebar

Grip

Assembly and Installation Handlebar

Install Cover grip cap Cover throttle cable cap

Hot starter lever holder Bolt hot starter lever holder

Handlebar Chas

Steering

Steering Chas

Steering Removal

Steering Chas

Ball race

Ring nut

Bearing lower

Take care not to damage the steering shaft thread

Under bracket

Bearing and ball race

Install Plain washer Ring nut

Install Trip meter Bolt trip meter

Swingarm

Swingarm Chas

Swingarm Removal

Swingarm Disassembly

Swingarm Disassembly

Relay arm

Swingarm

Bearing and oil seal

Connecting rod

Installed depth of bearings a 5 mm 0.20 Swingarm

Installed depth of bearings a 5 mm 0.20

80 Nm 8.0 m · kg, 58 ft · lb

Tighten Nut relay arm

Bolt support cover r= 10 mm 0.39

Rear Shock Absorber

Rear Shock Absorber Chas

Rear Shock Absorber Removal

Rear Shock Absorber Chas

Rear Shock Absorber Chas

EC586000

Rear shock absorber

Spring rear shock absorber

Installed depth of the bearing a 4 mm 0.16

Adjustment

Spring length installed a Standard Extent

Bolt rear frame lower

Rear Shock Absorber Chas

Wiring Diagram

Electrical Components and Wiring Diagram

Color Code

Function of Component

MAP-CONTROLLED CDI Unit

Inspection Steps

Ignition System

Engine Stop Button Inspection

Ignition System Elec +

Spark GAP Test

COUPLERS, Leads and Ignition Coil Connection Inspection

OFF

Main Switch Inspection

Ignition Coil Inspection

AC Magneto Inspection

Neutral Switch Inspection

CDI Unit Inspection

Starting Circuit CUT-OFF System Operation

Electric Starting System

Inspection Steps

Tor position

Couplers and Leads Connection Inspection

Starter Motor Operation

Starting Circuit CUT-OFF Relay Inspection

Starter Relay Inspection

Clutch Switch Inspection

Pull Free

Diode Inspection

Remove the diode from wire harness

Start Switch Inspection

Electric Starting System Elec +

Starter Motor Removal

Starter Motor

Starter Motor Disassem BLY

Elec

Min. commutator diameter 16.6 mm 0.65

Inspection and Repair

Mica undercut 1.5 mm 0.06

Be careful not to damage the brush during installation

Assembly

Min. brush length Mm 0.14

New

Charging System

000 r/min

Charging Voltage Inspection

Tester + lead → Red lead Tester lead → Black lead

DCV-20

TPS Throttle Position Sensor System

TPS Coil Inspection

TPS Throttle Position Sensor System Elec +

Tester + lead → Yellow lead Tester lead → Black lead

TPS Replacement and Adjustment

DCV

58 ~ 0.78

Tester + lead → Blue lead 1 Tester lead → Black/Blue lead

TPS Input Voltage Inspection

~ 6 DCV-20

Lighting System

RECTIFIER/REGULATOR Inspection

Lights Switch Inspection

Tester + lead → Yellow lead Tester lead → Blue lead

No continuous while being → Replace

Carburetor setting

Setting

Humidity

Effects of the setting parts on the throttle valve opening

Setting T U N

Main system

Effects of changing the main jet reference

Main jet adjustment

Pilot system

Standard main jet #150 #160

Effects of adjusting the pilot screw reference

Pilot screw adjustment

Standard pilot Screw position Example

Standard pilot jet #45 #48

Pilot jet adjustment

Effects of adjusting the pilot jet reference

Jet needle groove position adjustment

Effects of changing the jet needle reference

Jet needle adjustment

Standard jet needle

Obdut Obduq

#DUW

STD

#DUS

#DUV

Examples of carburetor setting depending on symptom

Standard secondary reduction ratio 50/14

Selection of the secondary reduction ratio Sprocket

Size Part number

5NG-17460-00

9383E-14215

For CDN, EUROPE, AUS, NZ and ZA

Change in level and characteristics of fork oil

Front fork setting

Setting of spring after replacement

Spring preload adjustment

Setting

Rate

Part Number

Spring

Mark

Choosing set length

Rear suspension setting

Standard figure 90 ~ 100 mm 3.5 ~ 3.9

EC72G001

Setting

Adjustment b

Rear shock absorber setting parts

Spring Free Extent

Suspension setting

One passenger is astride seat

Printed on Recycled Paper Shingai Iwata Shizuoka Japan