CHAPTER 4 IMAGE FORMATION SYSTEM

5. Application Voltage Level (APVC) for the Primary Charging Roller and Scanning Lamp On Voltage Level Automatic Correction

Changes in the static latent image could cause the quality of copies; such changes, in turn, may be attributed to the following factors:

•changes in the drum sensitivity

•changes in the charge volume of the primary charging roller.

These changes occur as a result of changes in the environment in which the copier is installed (temperature, humidity), deterioration of parts, or wear and dirt on parts.

In the case of the copier, the light potential (VL) and dark potential (VD) tend to increase, and the primary charging roller bias application voltage level is corrected (APVC control) to compensate for possible problems while at the same time executing scanning lamp on voltage level correction (ALVC control); specifically, the control serves to ensure constant light potential (VL) and dark potential (VD).

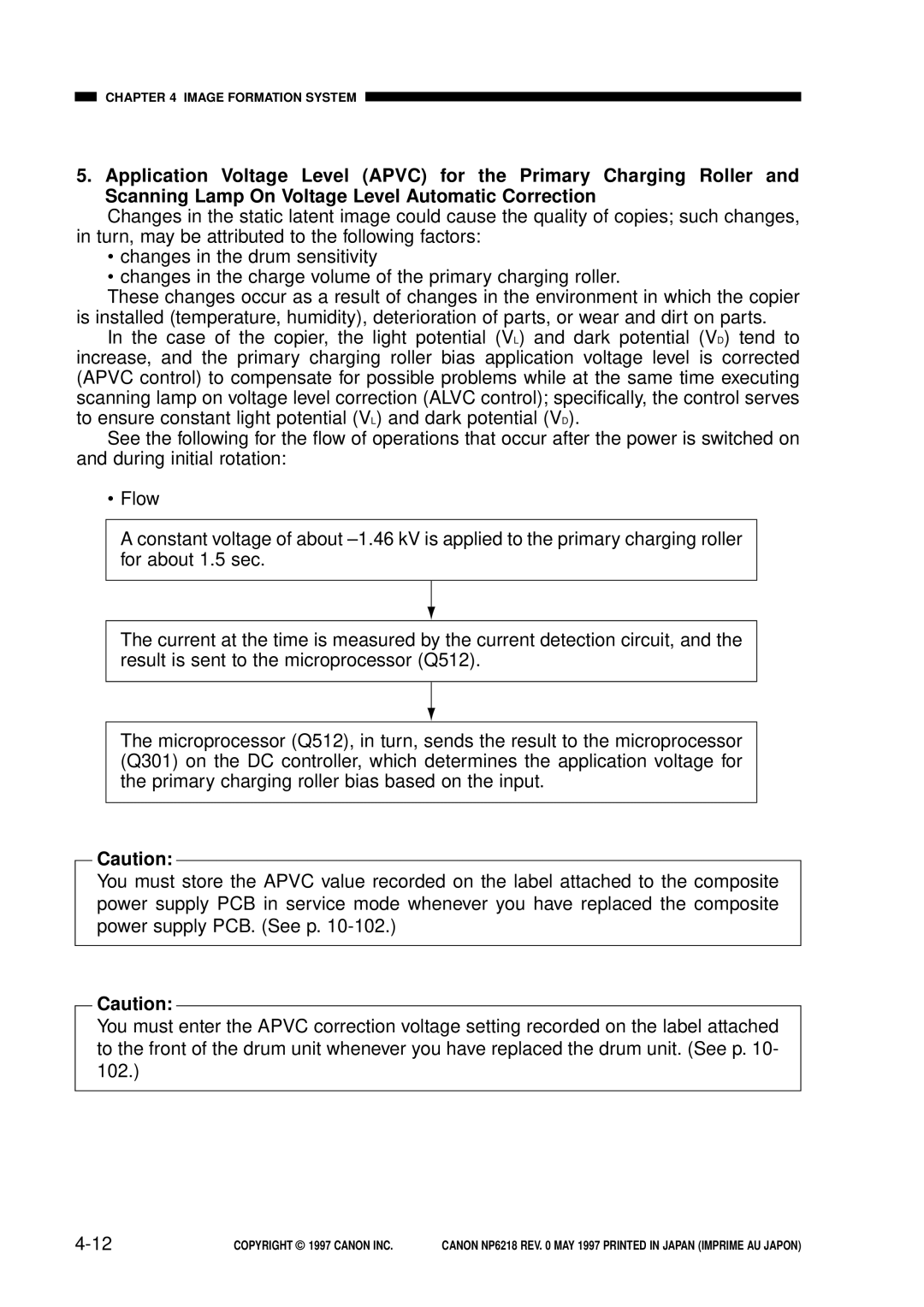

See the following for the flow of operations that occur after the power is switched on and during initial rotation:

•Flow

A constant voltage of about

The current at the time is measured by the current detection circuit, and the result is sent to the microprocessor (Q512).

The microprocessor (Q512), in turn, sends the result to the microprocessor (Q301) on the DC controller, which determines the application voltage for the primary charging roller bias based on the input.

Caution:

You must store the APVC value recorded on the label attached to the composite power supply PCB in service mode whenever you have replaced the composite power supply PCB. (See p.

Caution:

You must enter the APVC correction voltage setting recorded on the label attached to the front of the drum unit whenever you have replaced the drum unit. (See p. 10- 102.)

COPYRIGHT © 1997 CANON INC. | CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON) |