FY8-13EX-000

Copyright 1997 Canon INC

Introduction

Copyright 1997 Canon INC

Iii

System Configuration

General Description Copyright 1997 Canon INC

Contents

Image Formation System

Exposure System

Vii

PICK-UP/FEEDING System

Viii

Fixing System

Installation

Maintenance and Servicing

EXTERNALS/AUXILIARY Mechanisms

II. Standards and ADJUSTMENTS..10-5

Troubleshooting

Arrangement and Functions

Xii

Appendix

Chapter General Description

Practical basic features

Features

Multiple front loading and multifeeder for space saving

Office amenities and ecology

Copier

II. Specifications

Type

System

Features

201 Standard Reproduction Ratios

Others

202 Copying Speed

Cassette Feeding Module-B2/Cassette Feeding Module-A2

Exterior View

III. Names of Parts

Body

Cross Section

Cassette Feeding Module-A2

Control Panel

IV. Operation

Operation Mode

Making Two-Sided/Overlay Copies manual

Outline

User Mode

Changing the Auto Power-Off Time

Common Operations Keys to Use in User Mode

Operation

Changing the Auto Clear Time

Reference

Zoom Fine-Adjustment

Turning On and Off the Auto Cassette Change Mechanism

Cleaning the Feeder with ADF installed-option

Initializing User Mode

Selecting the Density Adjustment Method for Standard Mode

Quick Guide to User Mode

Handling the Toner Bottle

VI. Routine Maintenance by the User

Outline

VII. Image Formation

General Description

General Description Copyright 1997 Canon INC

Chapter Basic Operation

Functional Construction

Basic Construction

CPU

Outline of the Electrical Circuitry

Stby Intr Scfw Scrv Lstr AER

Basic Sequence of Operations 2 copies continuous, AE

Mechanism

Main Motor Control Circuit

Inputs to the DC Controller PCB 1/3

Inputs to the DC Controller PCB

CSZ3 CSZ4

Inputs to the DC Controller PCB 2/3

Inputs to the DC Controller PCB 3/3

Outputs from the DC Controller PCB 1/3

Outputs from the DC Controller PCB

Mfpucld

Outputs from the DC Controller PCB 2/3

Hefd

Outputs from the DC Controller PCB 3/3

CS2

Inputs to and Outputs from the 1-Cassette Unit Driver PCB

C3VPD

Inputs to and Outputs from the 2-Cassette Unit Driver PCB

C2PUCLD

Basic Operation Copyright 1997 Canon INC

Chapter Exposure System

Varying the Reproduction Ratio

II. Lens Drive System

Chsld

Lens Motor Drive Circuit

Keeping the Lens Motor Stationary

Driving the Lens Motor

Stby Intr Scfw Scrv Lstr AER

Basic Sequence of Operations lens drive system non-Direct

Driving the Scanner

III. Scanning Drive System

Basic Sequence of Operations scanner

Relationship between the Scanner Sensor and Signals

Driving the Scanner Motor Outline

Exposure System

IV. Disassembly and Assembly

Scanner Drive Assembly

Detaching the Scanner Drive Motor

Detaching the Scanner Cable

Exposure System

Assembling the Mirror Position Tool

Routing the Scanner Cable

Set screws Loosen the set Screw to free Totation Pulley

Hook Wirespring Cable

Frontrear

Cleaning the Scanner No Mirror

Detaching the Lens Drive Motor

Lens Drive Assembly

Exposure System

Routing the Lens Cable

421 Lens Drive Assembly

Adjusting the Position of the Change Solenoid

Exposure System Copyright 1997 Canon INC

Chapter Image Formation System

Processes

Composite Power Supply PCB DC controller PCB

T101

On on

Basic Sequence of Operations image formation system

Flprht

Controlling the Scanning Lamp

Pre-Heating Control scanning lamp

Turning On and Off the Scanning Lamp

OFF

Controlling the Intensity of the Scanning Lamp FL1

Controlling the Fluorescent Lamp Heater

Fluorescent Lamp Protection Mechanism

Fluorescent Lamp Automatic

Mpwm

Controlling the Primary Charging Roller Bias

Turning On and Off the Primary Charging Roller Bias

Image Formation System

Controlling the Transfer Roller Bias

Cleaning Bias

Transfer Bias

Reference Bias Atvc

Tfwon Tfwpwm Tfws Trevon

Turning On and Off the Transfer Roller Bias

Current Limiter Circuit cleaning bias

Controlling the Transfer Bias to a Constant Voltage

Current Limiter Circuit transfer bias

Controlling the Static Eliminator Bias

Ensuring Proper Separation of Thin Paper

Switching the Static Eliminator Bias Voltage Level

Bssld

Controlling Blank Exposure

Blanking Whiting of Non-Image Areas for Reduction

Primary Charging Roller Cleaning Operation

Controlling the Primary Corona Roller Cleaning Mechanism

Releasing the Transfer Roller

II. Developing Assembly and Cleaning Assembly

Controlling the Toner Level Detection

Stby

Mpwm

Controlling the Development Bias

Turning On and Off the AC Component of the Development Bias

Control Method

Automatic Control of Copy Density

207 Area Read by the AE Sensor Reference

AE Adjustment

III. Disassembly and Assembly

Illumination Assembly

Detaching the Scanning Lamp/Fluorescent Lamp Heater

Image Formation System

~5mm 60mm

306 front view

Detaching the Blank Exposure Assembly

Detaching the Blank Exposure Lamp

Detaching the Blank Shutter Solenoid

314a

Positioning the Blank Shutter Solenoid

Positioning the Left/Right Margin

Routing the Blanking Cable

Detaching the Drum Unit

Drum Unit

Cleaning

Detaching the Primary Corona Assembly

Primary Corona Assembly

Cleaning the Cleaning Pad and the Primary Corona Roller

Positioning the Solenoid for the Primary Charging Roller

Transfer Charging Assembly

Detaching the Transfer Roller

Attaching the Drum Heater

Image Formation System

Image Formation System

Removing the Developing Assembly

Removing the Blade Assembly

Developing System

Removing the Developing Cylinder Side Seal

Image Formation System

Image Formation System

Installing the Side Seal and the Blade Assembly

Image Formation System

Chapter PICK-UP/FEEDING System

PICK-UP/FEEDING System

PS4

II. PICK-UP Operation Copier

Sequence of Operations pick-up/feeding assembly A4, 2 copies

Pick-Up Operation

III. PICK-UP from the Cassette Feeding MODULE-A2

Intr Scfw Scrv Scfw Scrv Lstr

Sequence of Operations cassette 2 A4, 2 copies

PS5

IV. Multifeeder

Identifying the Size of Paper on the Multifeeder

Intr Scfw Scrv Scfw Lstr

Sequence of Operations multifeeder A4, 2 copies

Identifying the Cassette Size

Guide plate horizontal Paper size lever Guide plate vertical

VI. Identifying Jams

Pre-Registration Delay Jam

Pre-Registration Stationary Jam

Pre-Registration Timing Jam

Separation Stationary Jam

Separation Delay Jam

Delivery Stationary Jam

Delivery Delay Jam

VII. Disassembly and Assembly

Pick-Up Assembly

Detaching the Pick-Up Roller Unit

PICK-UP/FEEDING System

PICK-UP/FEEDING System

Detaching the Pick-Up Roller

Detaching the Pick-Up Clutch

Points to Note When Attaching the Pick-Up Roller

Detaching the Separation Pad

Pick-Up from the Cassette

Adjusting the Left/Right Registration

Detaching the Multifeeder Assembly

Multifeeder Assembly

Detaching the Multifeeder Pick-Up Roller Unit

Detaching the Multifeeder Pick-Up Roller

Front of copier

Detaching the Multifeeder Drive Unit

Detaching the Multifeeder Clutch

Positioning the Multifeeder Assembly paper guide plate cam

Adjusting the Left/Right Registration

Registration Roller Assembly

Detaching the Registration Clutch

Detaching the Upper Registration Roller

PICK-UP/FEEDING System

Detaching the Lower Registration Roller

Detaching the Feeding Belt

Feeding Assembly

PICK-UP/FEEDING System

Cassette Feeding Module

Detaching the Copier from the Cassette Feeding Module

Detaching/Attaching the Pick-Up Roller

Chapter Fixing System

Basic Operations

Pwsw

Controlling the Fixing Heater Temperature

Reference

Controlling the Supply Power for the Fixing Heater

Protection Mechanism

Detecting Overheating at the End of the Fixing Heater

Thermistor TH1, TH2

Thermal Fuse FU1

Correcting Displacement of the Fixing Film

OFF

Fixing System

Controlling the Fixing Film Motor

II. Disassembly and Assembly

Fixing Assembly

Construction1

Detaching the Upper Fixing Unit

Fixing System

Fixing System

Fixing System

Fixing System

Fixing System

Fixing System

Fixing System

Points to Note When Attaching the Heater Connector

Points to Note When Attaching the Fixing Film

Adjusting the Fixing Film Drive Roller Pressure

Points to Note When Replacing the Fixing Upper Unit

Fixing System

Detaching the Lower Fixing Unit

Fixing System

Adjusting the Lower Fixing Roller Nip

Measuring the Nip

Delivery Assembly

Fixing System Copyright 1997 Canon INC

Chapter

Power Supply

Power Supply Circuit Assembly

EXTERNALS/AUXILIARY Mechanisms Copyright 1997 Canon INC

Error in the High-Voltage Output Data

Detecting Errors in the Power Supply PCB

Low-Voltage Output Data Error

Overcurrent in the Low-voltage Power Supply

Protection Mechanisms for the Power Supply Circuit

External Covers

Cover

EXTERNALS/AUXILIARY Mechanisms

Detaching the Control Panel

Detaching the Exhaust Fan

Fans

Main Motor/Main Drive Assembly

Detaching the Main Drive Assembly

Detaching the Main Motor Unit

EXTERNALS/AUXILIARY Mechanisms

Routing the Drive Belt

Detaching the Pick-Up Drive Unit

Cassette unit

Detaching the Cassette Motor

Detaching the Cassette Driver PCB

Points to Note When Replacing the DC Controller PCB

DC Controller PCB

Detaching the DC Controller PCB

Detaching the Composite Power Supply PCB

Composite Power Supply PCB

EXTERNALS/AUXILIARY Mechanisms

Points to Note When Handling the Composite Power Supply PCB

Points to Note When Replacing the Intensity Sensor

Points to Note When Replacing the AE Sensor

AE Sensor PCB

Intensity Sensor PCB

EXTERNALS/AUXILIARY Mechanisms Copyright 1997 Canon INC

Chapter Installation

Selecting the Site

Unpacking and Removing Fixings

II. Unpacking and Installing the Copier

Installation

Installation

Turning On the Copier

Installation

Installation

Checking the Images and Operations

Attaching the Drum Unit

Changing the Cassette Size

A5 R A4

Set the paper size plates selected in step

Direct position refers to

III. Relocating the Copier

IV. Replacing the Drum Unit

Go through the following when replacing the drum unit

Installation

Installation

Installing the Control Card IV N

Installation

Unpacking

VI. Cassette Heater KIT 5 Installation PROCE- Dure

Installation to a Cassette Feeding Module-A2/B2

Screws

Tie-wrap Connector Cord clamp

Copiers connector Molded member Copiers base plate

Relay harness

Installation

VII. Installing the Remote Diagnostic Device

Installation to the Copier

Installation

Installation

SW2 SW3

LED1 LED2 LED3 BAT1

AII

Bits on SW2 Setting

SW2-3

Shift bit 6 of the DIP switch 2 !9on the RDD’s PCB to OFF

Installation

Installation

Installation

Chapter Maintenance and Servicing

Periodically Replaced Parts

Periodically Replaced Parts

II. Durables

Pick-up roller FB2-2251-000 100,000

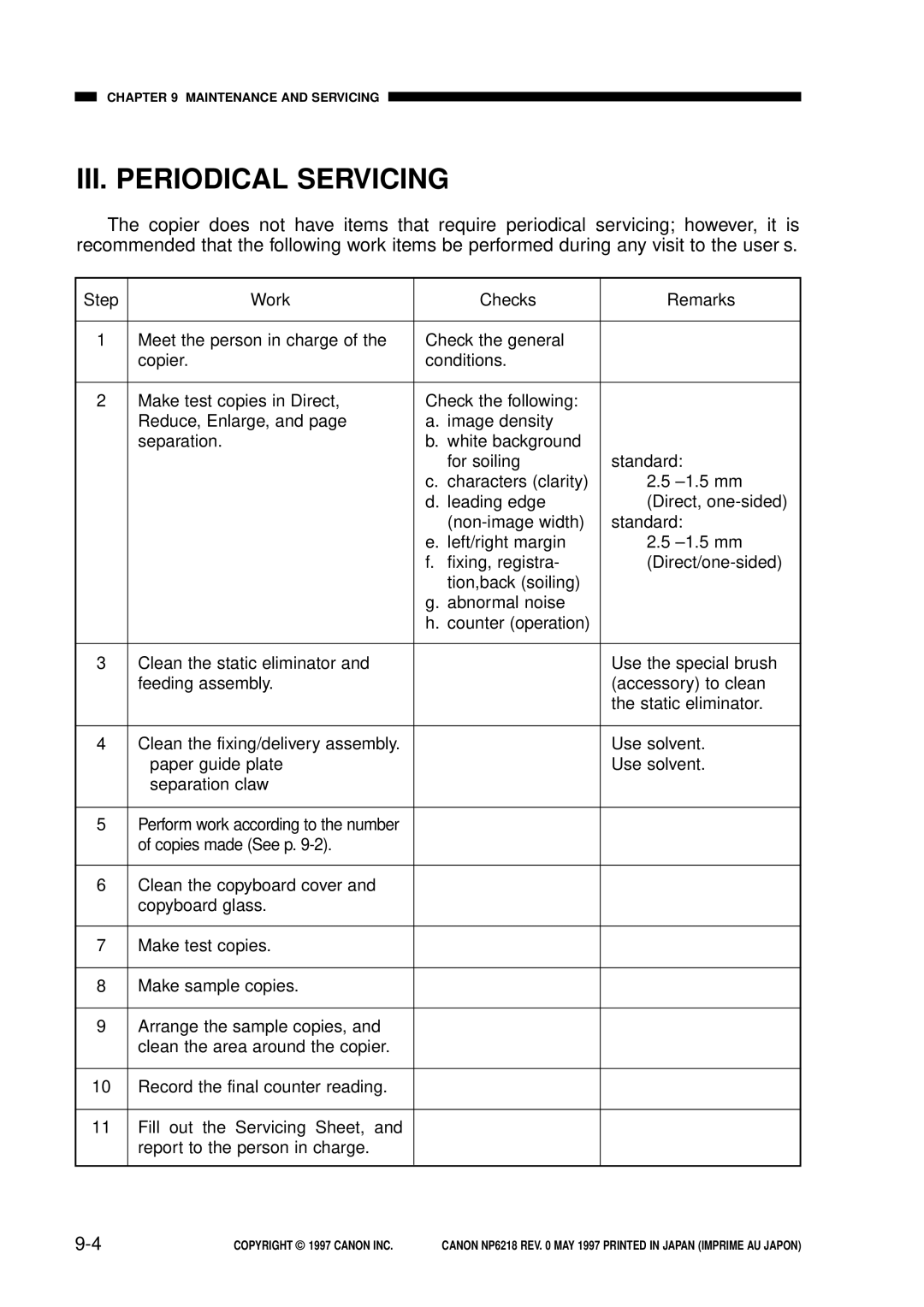

III. Periodical Servicing

IV. Servicing Chart

Maintenance and Servicing

Chapter Troubleshooting

10-1

Guide to Troubleshooting Tables

10-2

Maintenance and Inspection

Image Adjustment Basic Procedure

10-3

10-4

Periodical Servicing

II. Standards and Adjustments

Image Adjustment

10-5

10-6

10-7

10-8

10-9

Adjusting the Left/Right Margin No left/right margin

10-10

Adjusting the Scanning Lamp Intensity

10-11

10-12

210 DC Controller PCB

10-13

10-14

Exposure System

Routing the Scanner Drive Cable

10-15

10-16

Adjusting the Scanner Cable Tension

Assembling the Mirror Positioning Tool

10-17

10-18

10-19

220 front view

10-20

Positioning the Change Solenoid

10-21

Image Formation System

10-22

Routing the Blank Shutter Cable

10-23

After Replacing the Drum Unit

10-24

Orientation of the Pick-Up Roller

Pick-Up/Feeding System

Orientation of the Multifeeder Pick-Up Roller

10-25

10-26

Positioning the Paper Guide Plate Cam multifeeder

10-27

Fixing System

10-28

236 rear view

10-29

Points to Note after Replacing the Fixing Upper Unit

10-30

Adjusting the Nip

10-31

Storing the Fixing Heater Resistance

240 Heater Stay Side Plate rear 10-32

Setting the Fixing Heater Temperature Control Value

10-33

Example

10-34

After Replacing the PCB

Electrical

Clearing the Back-Up RAM

10-35

10-36

Checking the Photointerrupters

10-37

Copier

PS9

10-38

10-39

Cassette Feeding Unit

10-40

10-41

10-42

10-43

Adjusting the Multifeeder Paper Width Sensor

10-44

Setting the Paper Size for the Universal Cassette

Initial Checks

III. Troubleshooting Image Faults

10-46

10-47

10-48

Samples of Image Faults

Troubleshooting Faulty Images

Copy is too light half-tone only

10-49

10-50

10-51

10-52

10-53

Copy is foggy overall

10-54

Copy has black lines vertical, fine

10-55

Copy has white spot vertical Copy has white lines vertical

10-56

Copy has white spots horizontal

10-57

Back of the copy is soiled

Copy has a fixing fault

15, 16, 17 The leading edge of the copy is displaced

10-58

10-59

Copy has a blurred image

10-60

Copy is foggy horizontal

10-61

Copy has poor sharpness

Copy is blank

Copy is solid black

10-62

Troubleshooting Malfunctions

IV. Troubleshooting Malfunctions

E000

10-63

E001

E002, E003

10-64

E004

E007

10-65

E010

E030

10-66

E064

E202 keys on control panel invalidated

10-67

11. E220

10. E210

12. E240

10-68

14. E710, E711, E712, E717

13. E261

15. E803

10-69

10-70

AC power supply is absent

10-71

DC power supply is absent

Blank shutter fails to move

Photosensitive drum fails to rotate

10-72

Pick-up operation fails from cassette

Pick-up operation from the multifeeder fails

10-73

Scanner fails to move forward/in reverse

Registration roller fails to rotate

10-74

Scanning lamp fails to turn on

Lens fails to move

10-75

Fixing heater fails to operate

Add paper indicator fails to turn off

Pre-exposure lamp fails to turn on

10-76

10-77

Jam message fails to turn off

Troubleshooting Feeding Problems

Jams copy paper

10-78

10-79

Pick-Up Assembly

Fixing/Delivery Assembly

Separation/Feeding Assembly

Double feeding

Feeding Faults

Wrinkling

10-81

VI ARRANGEMENT/FUNCTIONS of the Electrical Parts

Sensors

10-82

10-83

10-84

Clutches, Solenoids, and Switches

10-85

10-86

Motors, Heaters, and Lamps

10-87

10-88

PCBs

10-89

10-90

Cassette Feeding Module A2

10-91

Photointerrupter

Variable Resistors VR and Check Pins by PCB

DC controller PCB

10-92

10-93

Composite power supply PCB

Using Service Mode

VII. Service Mode

Activating Service Mode

10-94

Using Adjustment Mode 3 and Specification Mode

Selecting a Service Mode

Using Operation/Inspection Mode

Clearing Stored Error Code

10-96

Recording on the Service Mode Label

10-97

Control Display Mode

10-98

10-99

O Mode

10-100

No /202/203/204 Port C Digital Display

10-101

Port H Display

10-102

Adjustment Mode

10-103

10-104

10-105

Operation/Inspection Mode

10-106

10-107

Specification Settings Mode

10-108

Counter Mode

10-109

VIII. Self Diagnosis

10-110

E003

10-111

E210

10-112

10-113

E400

10-114

E500

10-115

10-116

Appendix

A4, 2 copies, Direct, from copier cassette

General Timing Chart

Signals and Abbreviations

Signals and Abbreviations

General Circuit Diagram

Copyright 1997 Canon INC

Special Tools

MEK

SOLVENTS/OILS

Canon INC

This publication is printed on 70% reprocessed paper