Maintenance and Troubleshooting

Robotics problems

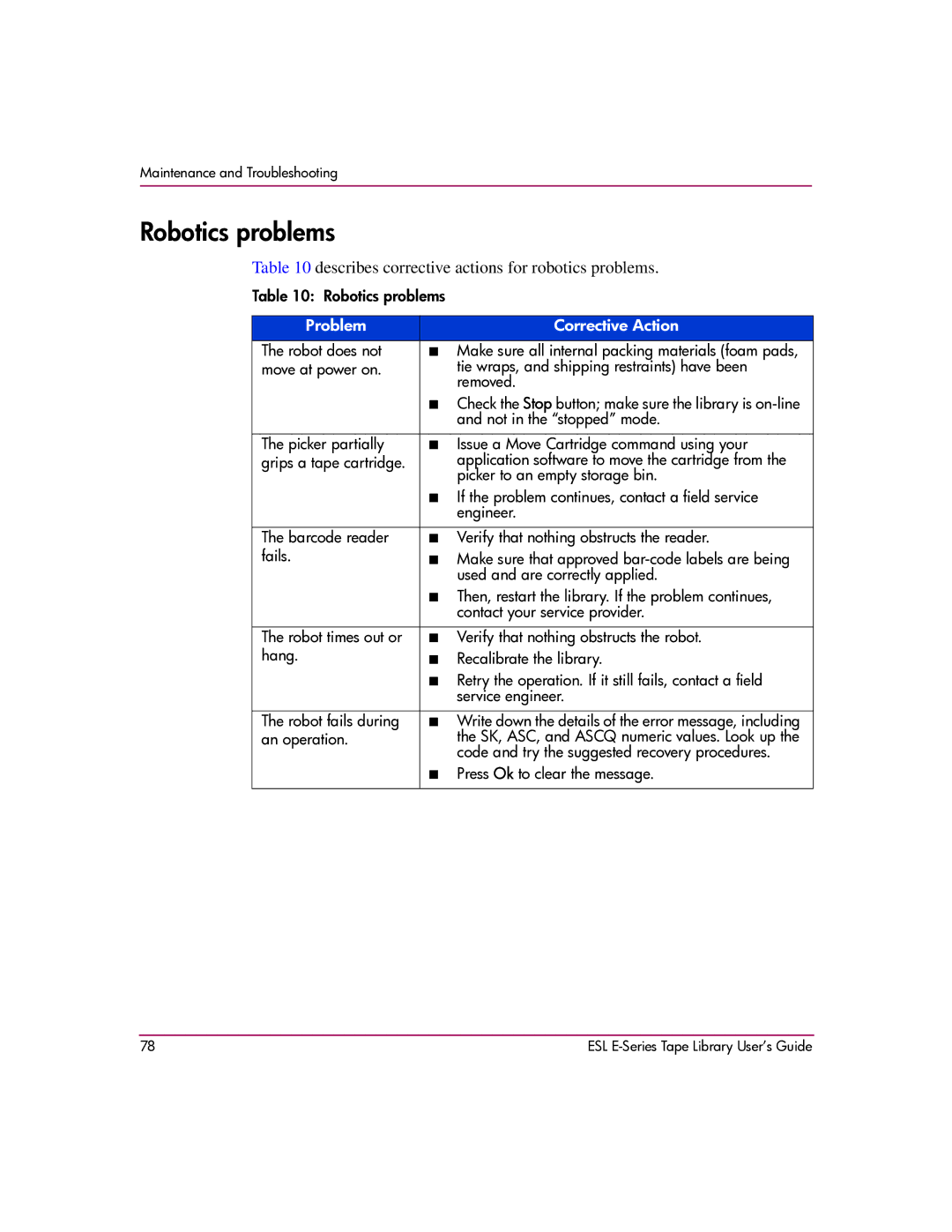

Table 10 describes corrective actions for robotics problems.

Table 10: Robotics problems

Problem | Corrective Action |

The robot does not | ■ Make sure all internal packing materials (foam pads, |

move at power on. | tie wraps, and shipping restraints) have been |

| removed. |

| ■ Check the Stop button; make sure the library is |

| and not in the “stopped” mode. |

|

|

The picker partially | ■ Issue a Move Cartridge command using your |

grips a tape cartridge. | application software to move the cartridge from the |

| picker to an empty storage bin. |

| ■ If the problem continues, contact a field service |

| engineer. |

|

|

The barcode reader | ■ Verify that nothing obstructs the reader. |

fails. | ■ Make sure that approved |

| used and are correctly applied. |

| ■ Then, restart the library. If the problem continues, |

| contact your service provider. |

|

|

The robot times out or | ■ Verify that nothing obstructs the robot. |

hang. | ■ Recalibrate the library. |

| ■ Retry the operation. If it still fails, contact a field |

| service engineer. |

|

|

The robot fails during | ■ Write down the details of the error message, including |

an operation. | the SK, ASC, and ASCQ numeric values. Look up the |

| code and try the suggested recovery procedures. |

| ■ Press Ok to clear the message. |

|

|

78 | ESL |