DA500/DA550 Basics • 3

Setting Up A Job (continued)

5. Load Material

Once your printer is set up, you can load material and make a test print. Avoid misfeeds by following these precautions:

1.Make sure the input area is free of dust and other matter.

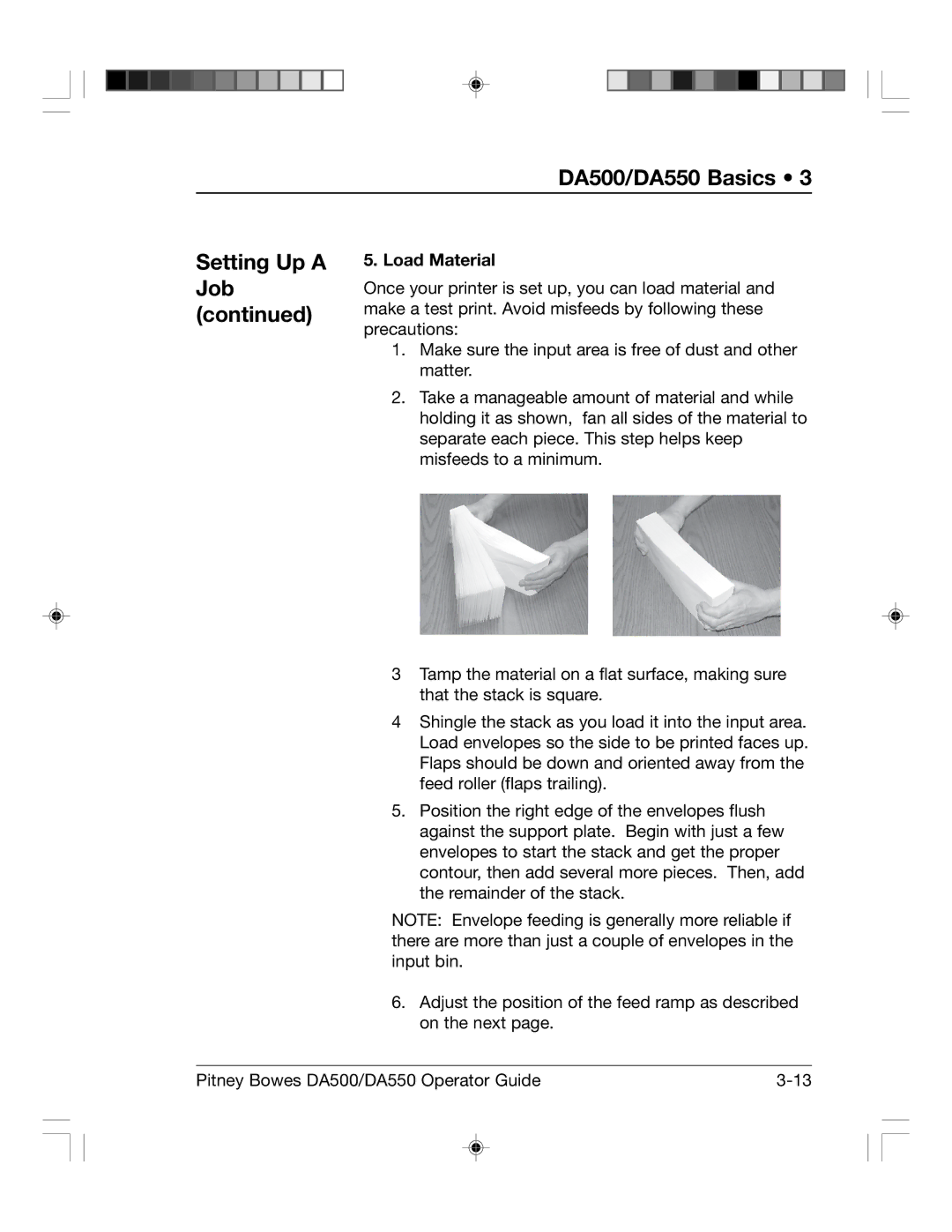

2.Take a manageable amount of material and while holding it as shown, fan all sides of the material to separate each piece. This step helps keep misfeeds to a minimum.

3Tamp the material on a flat surface, making sure that the stack is square.

4Shingle the stack as you load it into the input area. Load envelopes so the side to be printed faces up. Flaps should be down and oriented away from the feed roller (flaps trailing).

5.Position the right edge of the envelopes flush against the support plate. Begin with just a few envelopes to start the stack and get the proper contour, then add several more pieces. Then, add the remainder of the stack.

NOTE: Envelope feeding is generally more reliable if there are more than just a couple of envelopes in the input bin.

6.Adjust the position of the feed ramp as described on the next page.

Pitney Bowes DA500/DA550 Operator Guide |