Chapter 12—Verifying accuracyPowerLogic™ PM5300 series user guide

3600 × (Maximum pulse frequency) 3600 × 25 Maximum Ptot =

Kmax9,999,999

Test points

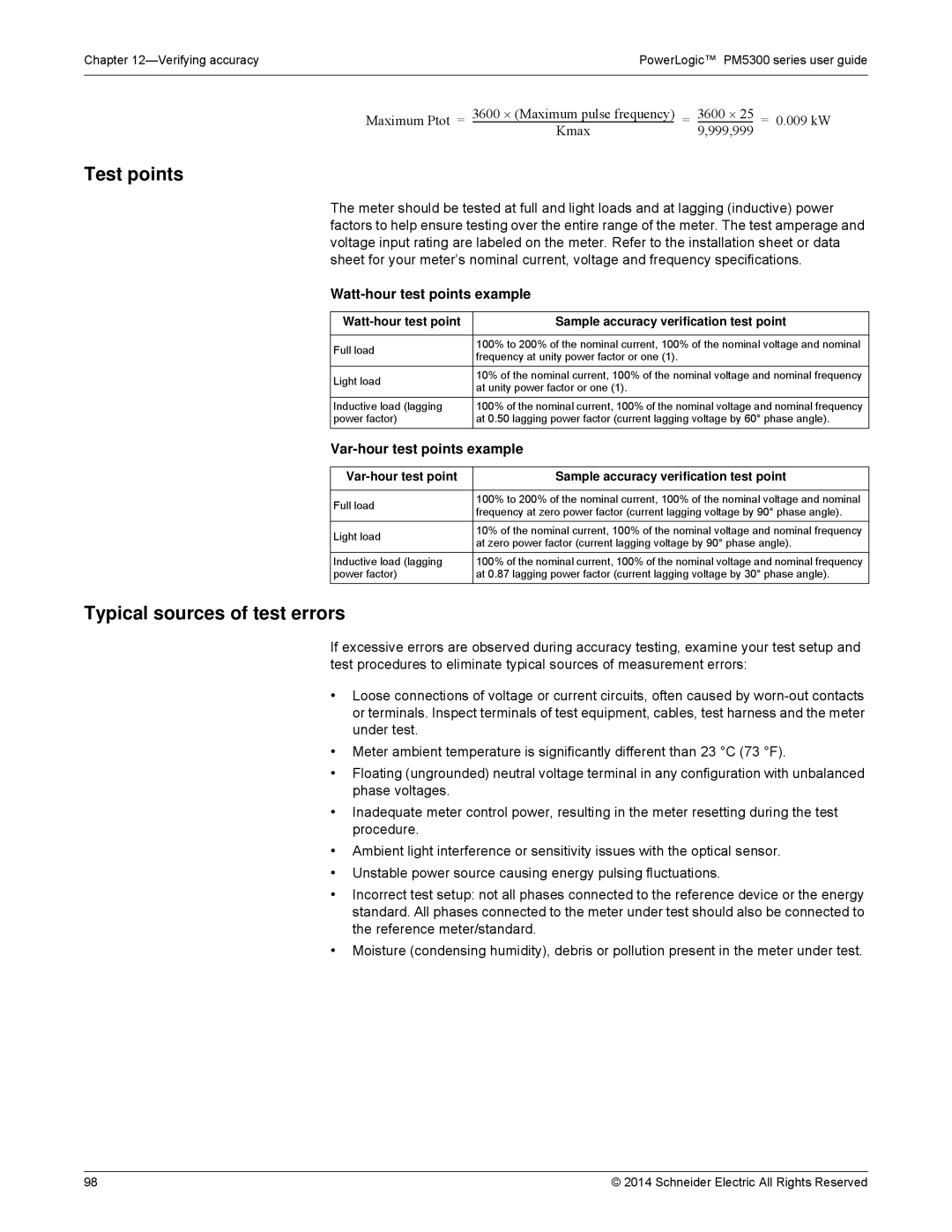

The meter should be tested at full and light loads and at lagging (inductive) power factors to help ensure testing over the entire range of the meter. The test amperage and voltage input rating are labeled on the meter. Refer to the installation sheet or data sheet for your meter’s nominal current, voltage and frequency specifications.

Watt-hour test points example

Sample accuracy verification test point | ||

|

| |

Full load | 100% to 200% of the nominal current, 100% of the nominal voltage and nominal | |

frequency at unity power factor or one (1). | ||

| ||

Light load | 10% of the nominal current, 100% of the nominal voltage and nominal frequency | |

at unity power factor or one (1). | ||

| ||

Inductive load (lagging | 100% of the nominal current, 100% of the nominal voltage and nominal frequency | |

power factor) | at 0.50 lagging power factor (current lagging voltage by 60° phase angle). |

Var-hour test points example

| Sample accuracy verification test point | |

|

| |

Full load | 100% to 200% of the nominal current, 100% of the nominal voltage and nominal | |

frequency at zero power factor (current lagging voltage by 90° phase angle). | ||

| ||

Light load | 10% of the nominal current, 100% of the nominal voltage and nominal frequency | |

at zero power factor (current lagging voltage by 90° phase angle). | ||

| ||

Inductive load (lagging | 100% of the nominal current, 100% of the nominal voltage and nominal frequency | |

power factor) | at 0.87 lagging power factor (current lagging voltage by 30° phase angle). |

Typical sources of test errors

If excessive errors are observed during accuracy testing, examine your test setup and test procedures to eliminate typical sources of measurement errors:

•Loose connections of voltage or current circuits, often caused by

•Meter ambient temperature is significantly different than 23 °C (73 °F).

•Floating (ungrounded) neutral voltage terminal in any configuration with unbalanced phase voltages.

•Inadequate meter control power, resulting in the meter resetting during the test procedure.

•Ambient light interference or sensitivity issues with the optical sensor.

•Unstable power source causing energy pulsing fluctuations.

•Incorrect test setup: not all phases connected to the reference device or the energy standard. All phases connected to the meter under test should also be connected to the reference meter/standard.

•Moisture (condensing humidity), debris or pollution present in the meter under test.

98 | © 2014 Schneider Electric All Rights Reserved |