Torque Specifications

Recommended fastener torque values are listed in the following tables. For critical applications, as determined by Toro, either the recommended torque or a torque that is unique to the application is clearly identified and spe- cified in this Service Manual.

These Torque Specifications for the installation and tightening of fasteners shall apply to all fasteners which do not have a specific requirement identified in this Ser- vice Manual. The following factors shall be considered when applying torque: cleanliness of the fastener, use of a thread sealant (e.g. Loctite), degree of lubrication on the fastener, presence of a prevailing torque feature (e.g. Nylock nut), hardness of the surface underneath the fastener’s head or similar condition which affects the installation.

As noted in the following tables, torque values should be reduced by 25% for lubricated fasteners to achieve the similar stress as a dry fastener. Torque values may also have to be reduced when the fastener is threaded into aluminum or brass. The specific torque value should be determined based on the aluminum or brass material strength, fastener size, length of thread en- gagement, etc.

The standard method of verifying torque shall be per- formed by marking a line on the fastener (head or nut) and mating part, then back off fastener 1/4 of a turn. Measure the torque required to tighten the fastener until the lines match up.

Product Records and Maintenance

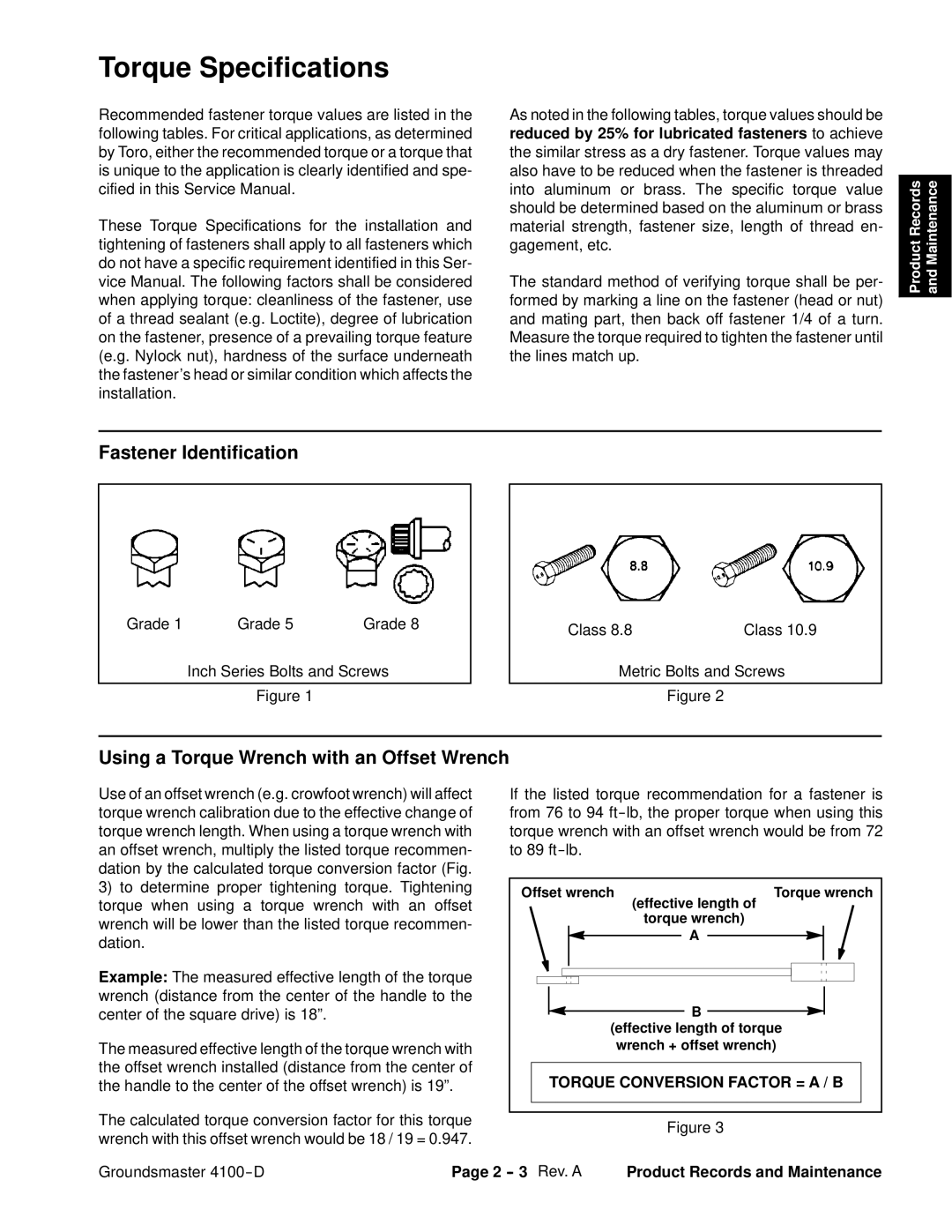

Fastener Identification

Grade 1 | Grade 5 | Grade 8 |

Inch Series Bolts and Screws

Figure 1

Class 8.8 | Class 10.9 |

Metric Bolts and Screws

Figure 2

Using a Torque Wrench with an Offset Wrench

Use of an offset wrench (e.g. crowfoot wrench) will affect | If the listed torque recommendation for a fastener is |

torque wrench calibration due to the effective change of | from 76 to 94 |

torque wrench length. When using a torque wrench with | torque wrench with an offset wrench would be from 72 |

an offset wrench, multiply the listed torque recommen- | to 89 |

dation by the calculated torque conversion factor (Fig. |

|

3) to determine proper tightening torque. Tightening | Offset wrench | (effective length of | Torque wrench | |

torque when using a torque wrench with an offset | ||||

|

| |||

wrench will be lower than the listed torque recommen- |

| torque wrench) |

| |

| A |

| ||

dation. |

|

| ||

|

|

| ||

Example: The measured effective length of the torque |

|

|

| |

wrench (distance from the center of the handle to the |

| B |

| |

center of the square drive) is 18”. |

|

| ||

| (effective length of torque | |||

The measured effective length of the torque wrench with |

| wrench + offset wrench) | ||

the offset wrench installed (distance from the center of | TORQUE CONVERSION FACTOR = A / B | |||

the handle to the center of the offset wrench) is 19”. | ||||

The calculated torque conversion factor for this torque |

| Figure 3 |

| |

wrench with this offset wrench would be 18 / 19 = 0.947. |

|

| ||

|

|

| ||

Groundsmaster | Page 2 | Product Records and Maintenance |