EX4 Series

Table of Contents

System Mode

EO18-33027

Rfid Analyze Tool

Periodic Maintenance Procedure

11-1

EO18-33027

Procedure

Unpacking

Open

Printer Installation

Maintenance

Printer Block Screw

OPENING/CLOSING the Printer Block

OPENING/CLOSING the TOP Cover

Removing the Side Panel L

Raise the print head block until it stops

Removing the Operation Panel

Hooks

Operation Panel Ass’y Operation Panel Harness

Installation Procedure for Optional Equipment

Disc Cutter B-EX204-QM-R

Hooker

Main PC Board CN15 Disc cutter PC Board Cutter Harness

Disassemble the frame into 3 parts

Rotary Cutter B-EX204-R-QM-R

Description ’ty/Unit Cutter Unit

SMW-4x8 Determine the position by fitting the two parts here

Do not

4x8 Screw

Harness Ass’y CN7 9 pins

CN15 9 pins

Cutter Unit SM-4 x 8 Screw Notch

Installation Procedure for Optional Equipment

Peel OFF Module B-EX904-H-QM-R

Turn the power off and disconnect the power cord

Hook

Installation Procedure for Optional Equipment

CN4

Selection Switch

TBD

Bush Cut Strip Sensor Harness

Adjustment

Ribbon Saving Module B-EX904-R-QM-R

Plunger Head Up Arm Spacer Solenoid SM-4x8 Screw Frame

CN2

RTC/USB host I/F card 1 pc

Installation Procedure

RTC/USB Host I/F Card B-EX700-RTC-QM-R

Remove the Blind Plate C from the back

Expansion I/O Interface Board B-EX700-IO-QM-R

Packing List

Remove the Blind Plate D from the back

Installation Procedure for Optional Equipment

Wireless LAN Board B-EX700-WLAN-QM-R

Installation Procedure

Installation Procedure for Optional Equipment

Parallel Interface card B-EX700-CEN-QM-R

Remove the Blind Plate a from the back

Re-attach the Side Panel L to the printer

System Mode

Operation Panel

Overview

Menu Item

SELF-DIAGNOSTIC Test

DIAG. menu item list

Menu operation procedure example

Counter Paramete Print Contents

PRINT1 ~ PRINT4

FEED1 ~ FEED4

Print

CUT

Adjust

Parameter Settings

Font

EX.I/O Mode

Reflect

LATIN9

LBL/RBN END

Command

Power Save Time

Maxi Code Spec

USB

Panel

Storage Area

RS-232C

Centro

LAN/WLAN

Default KEY

Wlan Mode

AES Tkip WPA Mode

Socket Port

Rfid

RTC

Auto Diagnostics/AUTO Diagnostics

Kanji None :0000

Print condition

Program B-EX4T1-G

Eeprom 256B

Sdram 32MB

SENSOR2

Head Rank

EXP.I/O NG

Expansion I/O check contents

Internal serial I/F check contents EX.232C NG

US, AU, KR2, TW SX704-RFID-U2-EU-R

SX704-RFID-U2-US-R

US, AU, TW

EU, SX704-RFID-U2-R

Basic S None

USB Memory NG

Basic M None

Head broken dot check/HEAD Check

LCD Display Setting / Panel

Parameter Setting

„ Outline of Parameter Setting

1Printer setting / Printer SET

Forward feed standby position / Forward Wait POS

Setting for forward feed standby / Forward Wait

Media loading / Media Load

Standby action / FW/BK ACT

Back feed / Back Speed

Ribbon save / RBN Save

Pre peel-off / PRE Peel OFF

Standard speed/ STD 3ips Low speed / LOW 2ips

ESC LF NUL / Manual

Soft control setting / Software SET

Menu list Soft control setting / Software SET

Control code / Code

Character code / Font Code

・ LATIN9

・ ESC, LF, NUL / ESC,LF,NUL

Peel-off wait status / Peel OFF Status

Manual selection / Manual

・ CODE1 ・ CODE2 ・ CODE3

Feed Key Function

Auto head broken check / Auto HD CHK

Character

Euro code / Euro Code

WEB Printer / WEB Printer

Paper / ribbon end / LBL/RBN END

External I/O mode / EX.I/O

Ribbon near end / RBN Near END

TYPE1:

Compatible with the current version

MaxiCode specification / Maxi Code

・ Disable / OFF ・ Standard / STD ・ Oracle / Oracle

2.16 XML

Print method / Energy Type

Power save time / PW Save Time

Threshold selection / Threshold Select

Machine name / Machine Name

LCD Language

Language of LCD display / LCD Language

Print page / Print

Menu list of Password setting / Password

Contrast adjustment / Contrast

Password setting / Password

Digit Hex Non Decimal

System Mode

Fine adjustment value setting/ Adjust SET

„ Outline of Printer Parameter Fine Adjustment

Cut position / CUT ADJ

Feed / Feed ADJ

Max Min Step Display Sign Integer Decimal Fullfil

Digit 50.0

+3.0mm Cut position Paper feed direction

(b)Operation example Issue count 2, Cut interval =

Cut position Head position

System Mode

Strip position fine adjustment 0mm +3.0mm

Back feed / Back ADJ

Density fine tune Thermal transfer / Tone ADJ.TRANS

Direction position / X Adjust

Digit 99.5 Decimal Exist Non

Digit Decimal Exist Non Step

Exist Non Step

Ribbon Rewinder / RBN ADJ.FW

Ribbon Feeder / RBN ADJ.BK

Refrective sensor fine tune / Threshold Refl

Transmissive sensor fine tune / Threshold Trans

EX4T1-G EX4T1-T Speed

+10step

Test Print

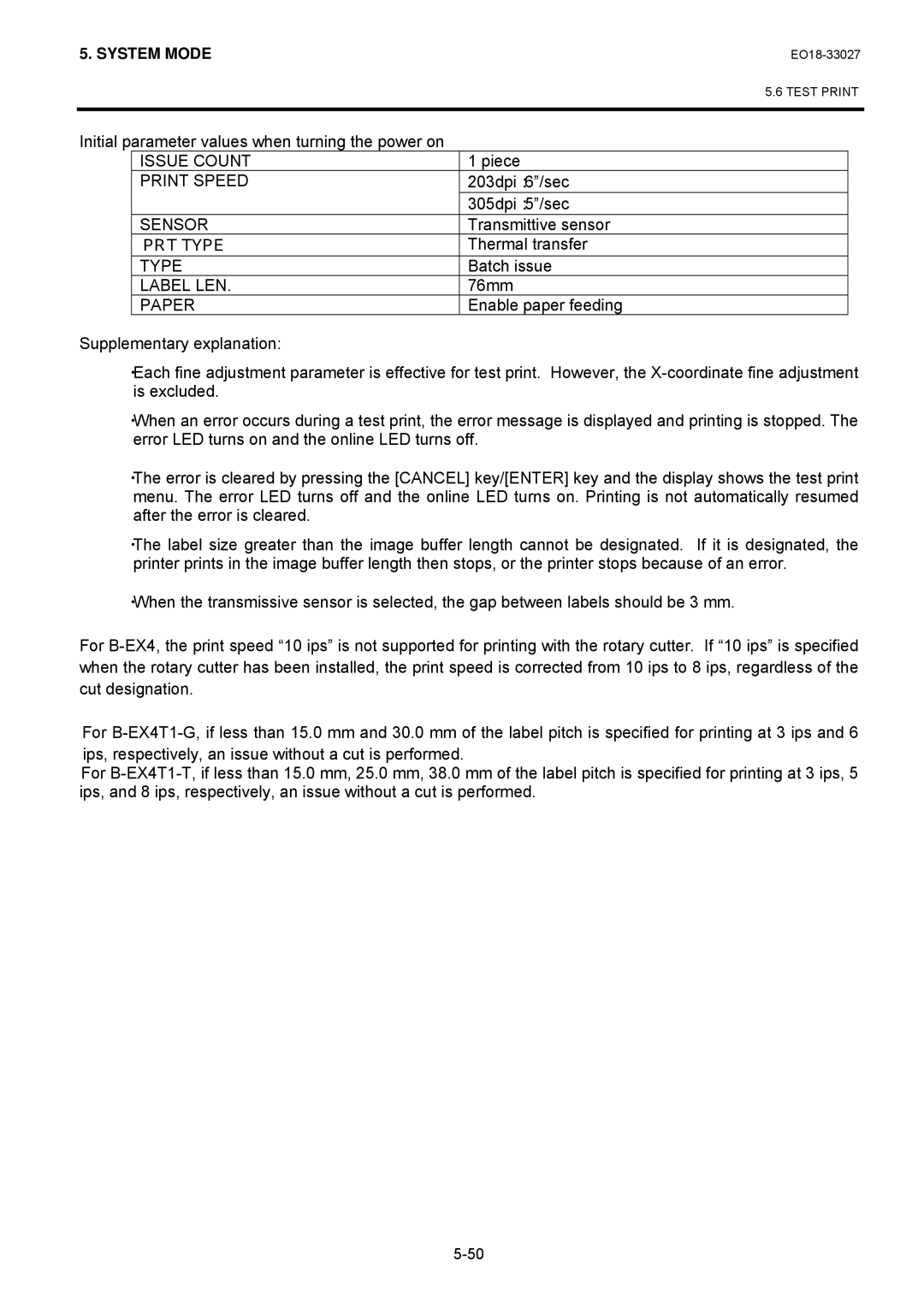

Print condition setting / Print Condition

Issue count / Issue Count

It sets printing condition of printer for test print

Sensor / Sensor

Issue type / Issue Type

Print speed / Print Speed

Print method / Print Type

Sensor

Issue Count

Print Speed

Type

2 1-dot slant line print / Slant LINE1DOT

3 3-dot slant line print / Slant LINE3DOT

Character print / Characters Barcode print / Barcode

Factory test / Factory Test

Auto print Transmissive / Auto Print Trans

Auto print Reflective / Auto Print Refl

Temperature sensor/ Temperature

Sensor Adjustment

„ Outline of the Sensor Adjustment

Reflective sensor / Reflect

Ribbon end / Ribbon

Transmissive / Trans

Paper empty level / PE REFL./TRANS

No RAM clear / no RAM Clear

RAM Clear

„ Outline of RAM Clear

This is a selection to prevent wrong user operation

MODE1 HU CUT/RWD

USB Status

TYPE1 XML STD

Ribbon Rewind

Parameter setting/Password setting

Print density Direct Thermal

Ribbon Back tension

None Even

Auto Snmp

INFRA/OPEN Wepoff

XON+READY Auto

ACK/BYSY TYPE1

RTC setting

User mode Auto paper measurement Function Enable/Disable

USB

IP Address Setting

Wire/Wireless LAN selection / LAN/WLAN

Network / Network Menu list of Network / Network Menu Item

Information

Network setting / Setting

Wlan Power Save Wins

Standard

Subnet mask / Subnet Mask

Basic information / Basic Information

Gateway / Gateway Address

Socket port / Socket Port

・ 11b/g ・ 11g

Wireless LAN standard / Wlan Standard

Wireless LAN connection mode / Wlan Mode

1.3.13 802.11b channel / 802.11b Channel

WEP default Key / Default KEY

Wlan power save / Wlan Power Save

1.3.14 802.11b transfer rate / 802.11b Baud

1.3.20 LPR

Wins

Wins Address / Wins Address

2 USB

Data length / Data Length

3 RS-232C

Baud rate / Speed

Stop bit / Stop BIT

・ TYPE1 ・ TYPE2

Centronics / Centro

4.1 ACK/BUSY

Input prime / Input Prime

Basic Setting

„ Outline of Basic Setting

Rfid Module Setting

„ Outline of the Rfid Module Setting

Test / Test

ID Read / ID Read

Module type / Module Type

SX704-RFID-U2 TAG ID

Module / Module

SX704-RFID-U2-CN-R

Country / Country

11.2.3Tag type / TAG

・ Auto

11.3.1Position adjustment for re-issue / ADJ Retry Position

RF channel / RF Channel

・ 2CH ・ 3CH ・ 4CH ・ 5CH ・ 6CH ・ 7CH ・ 8CH

11.3.3Read retry / Read Retry

11.3.2Issue retry label / Issue Retry Lables

Digit 255 Decimal Non

11.3.4Write retry / Write Retry

UHF setting / UHF Setting

11.4.1Output level / Power Level

SX704-RFID-U2-EU-R/US-R /CN-R

11.4.2Q value / Q Value

11.4.3AGC threshold / AGC Threshold

11.4.4Write AGC threshold / Write AGC Threshold

11.4.5Write retry minimum AGC / Write Retry MIN AGC

Password

11.5.1Tag test setting / TAG Check

Onaccess

Write data if access pass word matches to password setting

LCD Display example English

11.5.2Multi word write / Mult Write

11.5.3Carrier sense / Carrier Sense

„ LED function

For the following, refer to the parameter setting section

Cut issue mode when the disk cutter is used

„ Key function

Enter

„ Error messages

Cancel

Down

No Ribbon

OFF Blinking

Symbols in the message

„ LCD message and LED indication

Head Error

Dhcp Client

(Ex ) ESCT20G30LFNUL

(Ex ) ESCPC0010A00,0300,2,2,A,00,BLFNUL

LCD Display

Depressing Pause

Threshold Setting

Threshold Setting Operation Example (English)

Move to 3. Paper

Judgment display

Sensor type Judgement

On Line Mode

Online Mode LCD Display

Online Mode LCD Display Example (English)

Icon

Online Mode Display TRANSITION, Operation example (English)

Help Display

Help message for paper empty *1

Online mode Error content

Help Display TRANSITION, Operation EXAMPLE(English)

Periodic Maintenance Procedure

Remove paper debris or label glue from the media path

50 km

When the Strip Module is used

Troubleshooting

Troubleshooting

Rfid Analyze Tool

System Requirement

V1.5

Set up

Setup Disk Installation Setup Disk consists of one CD-ROM

Application Functions

Main Menu

File Menu

EO18-33027

End Exit Exits from the Analyze Tool program

Tool Menu

NON, XON, XON/XOFF

Test Option

Sheet Setting Makes settings for the media to be used

Select the test mode This menu is not available

Select the printer model

Example

Displays Printer Version and Rfid Module Version

Operating Procedure

Click on the Tool menu, and choose CommSetting

RTS/CTS+XON/XOFF

Rfid Analyze Tool

Tag Data

Rfid Analyze Tool

Write/Read Results Box When U2 is selected

Write/Read Results Box