Enhanced Ethernet PLC-5 Programmable Controllers

Important User Information

Summary of Changes

Additional Ethernet PLC-5 Controller Enhancement

Is on

Publication 1785-UM012D-EN-P July

Summary of Changes

Table of Contents

Memory

Chapter Communicating with

Controller-Resident I/O

Chapter

Communicating with Devices on a DH+ Link Chapter

Communicating with a PLC-5 Adapter Channel

Extended-Local I/O

Communicating with Devices on a Serial Link

Protecting Your Programs

Preparing Fault Routines

Appendix a System Specifications

Appendix B Processor Status File

Appendix C

Appendix D

Appendix E Switch Setting Reference

Appendix F Troubleshooting

Appendix G Cable Reference

Index

Related PLC-5 Documentation

Publication Title Publication Number

Term Definition

Controllers in this manual only

Manual Overview

This manual has three main sections Design Operate Maintain

Preface Publication 1785-UM012D-EN-P July

Extended-local I/O scanner

Using This Chapter Lay Out the System

For Information About

PLC-5/11, -5/20 and -5/26 controllers PLC-5/30 controllers

Identifying Controller Components

For the Front Panels

No parity

Keyswitch selects controller mode

Install memory module here Install battery here

Keyswitch selects controler mode

PLC-5/30 Controller Front Panell

4Understanding Your Programmable Controller

DF1 point-to-point One stop-bit 2400 bps

Install memory module here PLC-5 family member designation

Channel 2B status indicator lights green and red

Channel 1B status indicator lights green and red

External transceiver fuse Keyswitch selects controller mode

Configure this 3-pin port for

PLC-5/20E Controller Front Panel

6Understanding Your Programmable Controller

PLC-5/40E and -5/80E Controller Front Panels

8Understanding Your Programmable Controller

Install battery here PLC-5 family member designation

PLC-5/40L and -5/60L Controller Front Panels

If You Want to

This Capability Lets You

MCP

PLC-5/40

1771-ASB Remote I/O Link Cable Belden

Scanner-mode PLC-5 controller

At housekeeping

Connect the controllers via the remote I/O link

Controller transfers I/O data and status data using

12Understanding Your Programmable Controller

Publication 1785-UM012D-EN-P July

Scanner

14Understanding Your Programmable Controller

Using This Chapter

Selecting and Placing I/O

Selecting I/O Modules

Selecting I/O modules

Selecting I/O Module Density

Choose this Type

Explanation

Module Examples

Selecting and Placing I/O

Input Output

4Selecting and Placing I/O Publication 1785-UM012D-EN-P July

Placing System Hardware

Acceptable Range

51mm Wiring Duct 102mm 153mm

2Placing System Hardware

102mm 51mm2

Mount the I/O chassis horizontally

Troubleshooting is convenient

Preventing Electrostatic Discharge

Protecting Your Controller

RFI, we recommend a steel enclosure

Laying Out Your Cable Raceway

Categorize Conductors

Route Conductors

4Placing System Hardware

Side

Chassis Dimensions Series B

Laying Out Your Backpanel Spacing

Chassis and External Power Supply Dimensions

6Placing System Hardware

Ground Bus To Grounding Electrode System

Recommended Grounding Configuration for Remote I/O Systems

Enclosure

8Placing System Hardware Publication 1785-UM012D-EN-P July

Addressing I/O and Controller Memory

Classification Term Relation to Controller Memory

Addressing as It Relates to an I/O Terminal

2Addressing I/O and Controller Memory

Choosing an Addressing Mode

16-point Example

Input

Termi

Nals

Point Example

Point input module

Controller memory Rack

Group Point input module Point output module Word #

Example of Efficient I/O Image Table Use

6Addressing I/O and Controller Memory

Addressing Mode Guidelines

Addressing Summary

Addressing Block-Transfer Modules

Use this table as a quick reference for addressing

If Using this Slot Addressing Chassis Size Results

Assigning Racks

Slot Rack Racks 2 racks

8Addressing I/O and Controller Memory

When assigning remote I/O rack numbers, use these guidelines

Controller memory is divided into two basic areas

Understanding Data Storage Data-Table Files

Specify the file in which the data is stored

Formatted address

Data, you specify it with a formatted address

12Addressing I/O and Controller Memory

Addressing File Types

1000words

Words/1000 structures Structure

14Addressing I/O and Controller Memory

Understanding Program-File Storage

Valid Data Types/Values Are

Accepts Any

Program File Number of Words Used

Valid formats for addressing data files are

Addressing

Specifying I/O Image Addresses

To Specify the Address of a Use these Parameters

Where Is

Specifying Logical Addresses

TON, TOF, RTO

Specifying Indirect Addresses

Word Level Example Bit Level

Example Variable Explanation

Specifying Indexed Addresses

Value Base Address

Source N710 N720

N115 N1115

Specifying Symbolic Addresses

LS1

AUTO1

SW1

Optimizing Instruction Execution Time and Controller Memory

22Addressing I/O and Controller Memory

Following examples illustrate these concepts

Effectively Using I/O Memory

Use Application

Configuring the system for controller-resident I/O

Introduction to PLC-5 Controller Scanning

Program Scanning

2Communicating with Controller-Resident I/O

Transferring Data to Controller-Resident I/O

Transferring Discrete Data to Controller-Resident I/O

Transferring Immediate I/O Requests

Transferring Block-Transfer Data to Controller-Resident I/O

4Communicating with Controller-Resident I/O

Communicating to a remote I/O node adapter

Configuring a controller channel as a scanner

Communicating with Remote I/O

Can Connect

Category Product Catalog Number

An example remote I/O system looks like this

Introduction to Remote I/O

Block-transfer data with remote I/O devices

Designing a Remote I/O Link

Network using a daisy chain or trunk line/drop line

Configuration

Transmission rate. Configure all devices on a remote I/O

Link to communicate at the same transmission rate

Configuring a Controller Channel as a Scanner

Catalog Number Series

Specify the scan list Publication 1785-UM012D-EN-P July

Specify Channel Configuration Information

Define an I/O Status File

Diagnostic file

Scanner mode link 57.6, 115.2, and 230.4 kbps

This Field Define By Doing the Following

Cursor to the field, type an integer file number

Specify the Scan List

Scan list includes the following

Do the Following

For this Field Scan List Contains

10Communicating with Remote I/O

Communicating to a Remote I/O Node Adapter

Remote I/O Scan and Program Scan Loops

ASB Adapter Modules, Do the Following See

Appendix E

Troubleshooting Remote I/O Communication Difficulties

12Communicating with Remote I/O

Interrupt from STI or Fault Routine

Remote I/O Scan Extended Local

Racks

Adapter used in the remote I/O scan is the 1771-ASB

Description

Block-Transfer Minor Fault Bits

Minor Fault Description

Channel pairMinor fault bits set

PLC-5 typeMaximum number of command blocks

16Communicating with Remote I/O

Packet includes data if it is a block-transfer write

Block-transfer module

Transfer read

Block-Transfer Sequence with Status Bits

Yes Does this slot address

Does the module respond?

Yes See

Sets the error .ER bit Yes

18Communicating with Remote I/O

Yes Sets the done .DN bit

Go to

General Considerations

Retries request once more before setting the .ER bit

Block-Transfer Programming Considerations

For Controller-Resident Local Racks

20Communicating with Remote I/O

Status Field Location Description

Monitoring transmission retries

Monitoring Remote I/O Scanner Channels

Fault

Reset

Field indicating the rack was globally reset

Rack Address

Error

Messages sent with error

Messages Tab Messages = SDA messages + SDN messages

Messages unable to receive

N1547

24Communicating with Remote I/O

Defined I/O status file

Fault Bits

Present Bits Fault Bits Not Used

When you use a ladder program or the software to

Inhibit and reset an I/O rack, you must set or clear

Reset and inhibit bits that correspond to each quarter

Rack in a given chassis. Failure to set all the appropriate

Configuring communication to a PLC-5 adapter channel

Communicating with a PLC-5 Adapter Channel

Monitoring remote I/O adapter channels

Monitoring the status of the supervisory controller

2Communicating with a PLC-5 Adapter Channel

Configuring Communication to a PLC-5 Adapter Channel

Into for the supervisory controller

Remote I/O Adapter

Specify adapter settings Publication 1785-UM012D-EN-P July

Controller

Default is rack

Status information

Damage can result

Cursor to the field and select the desired rate

Specify the Discrete Transfer Configuration Files

6Communicating with a PLC-5 Adapter Channel

Discrete Data and Block-Transfer Status

8Communicating with a PLC-5 Adapter Channel

Input destination

Enter the file number decimal of the source data

Enter the word number decimal of the source data

Adapter’s input file

Programming Discrete Transfers Adapter Mode

Data to an Adapter Channel

10Communicating with a PLC-5 Adapter Channel

0x7 N5115

Configure Block-Transfer Requests

12Communicating with a PLC-5 Adapter Channel

Adapter Mode Configuration screen

Data Monitor screen

BT100 Has a length of 64 words

Must Match

BT000000 BT010000 BT011000 BT011001 BT011040

Examples of Block-Transfer Ladder Logic

14Communicating with a PLC-5 Adapter Channel

PLC-5 adapter-mode processor is configured for rack

Condition the use of BTR data with a data valid bit

BR0200 BWO200

Data Not Valid Bit

Locations of module 0 and 1 data

16Communicating with a PLC-5 Adapter Channel

Word For status Output File Input File Module

Adapter channel status

Monitoring the Status of the Adapter Channel

Status bits sent to scanner

When this Bits It Indicates

Monitoring the Status of the Supervisory Controller

Adapter

Messages received with error

Monitoring Remote I/O Adapter Channels

Page

Configuring the controller as an extended-local I/O

For Information About Go to

Scanner Monitoring extended-local I/O status

PLC-5/40L and -5/60L processor

Cabling

Form a custom cable length. For example, if you have a

You cannot connect two 2 m cables together. You would

Have to use the 5 m cable and have the extra 1 m as slack

Processor-resident local I/O racks

Numbered 4, 5, 10, 11, 12,

4Communicating with Extended-Local I/O

PLC-5/40L and -5/60L I/O Scanning and Update

Transferring Data

Extended Local I/O Data Exchange Image Update

Discrete Data Transfer

Remote I/O Scan

PLC-5/40L and -5/60L Extended-Local I/O Scan Time

Transferring Block Data

6Communicating with Extended-Local I/O

This formula assumes

Calculating Block-Transfer Completion Time

Where

Considerations for Extended-local Racks

8Communicating with Extended-Local I/O

This Field Specifies Configure by Doing the Following

Scan list Channel I/O configuration

Want to get status information for that channel

List

Or 1/2-Slot

Slot Logical rack Logical racks 11/2 logical rack

Remote I/O Scan List vs Extended-local I/O Scan List

10Communicating with Extended-Local I/O

An asterisk * after a range indicates the last

Valid rack entry

Automatically calculated based upon rack

Switch settings on the adapters are set correctly

Display the new configuration when you save edits

Monitoring Extended-Local I/O Status

Screen

Channel retry Word

Retry counts

Retry Word

Word Multiples Etc Entry

Page

Using the global status flag file

Selecting Devices That You Can Connect

Selecting devices that you can connect Link design

Estimating DH+ link performance Application guidelines

Link Design

Configuring the Channel for DH+ Communication

You must set switch assembly SW1 on the controller

Serial port or a PLC-5 coprocessor, use channel 2 for

Better overall system performance

Diagnostic file File containing the channel’s

Link ID Local link where the channel

Status information Words long

Other used file. Unpredictable machine damage can result

Using the Global Status Flag File

Pass data

System creates an integer file 64 words long

Information previously in this file is lost

Octal N107 Octal N1010 Octal N1015 Octal N1030

Files are updated during housekeeping

6Communicating with Devices on a DH+ Link

Status Field Words Description

Monitoring messages

Monitoring DH+ Communication Channels

Monitoring Data Sent with Acknowledgment

Need updates once per second

Noise or a cabling problem

Transmit confirm

Transmit NAK full

Monitoring Data Sent without Acknowledgment

10Communicating with Devices on a DH+ Link

Monitoring General Status

Noise or cabling problems

Linear scan failed

Started linear scan below for more information

Token retry

Sending Command Type Maximum Packet Station Size Data Words

Nodes

Size and Number of Messages

PLC-5

Completes the message transaction Station

Message Destination

14Communicating with Devices on a DH+ Link

Internal Processing Time

Average DH+ Link Response Time Test Results

16Communicating with Devices on a DH+ Link

Number of Controllers

50 W 100 W + 250 W X 500 W =Words

Application Guidelines

Number of Controllers

Page

This Is Normally Used When You Method

Communicating with Devices on a Serial Link

Choosing Between

RS-423

Using Channel

User Mode

System Mode

10-2Communicating with Devices on a Serial Link

Use this Mode For

DF1 Master Mode

DF1 Slave Mode

Point-to-Point

Method Option Name Principal Benefits

Polling Inactive Priority Stations

Changing Modes

Follow these guidelines

Port Transmission

Configuring Channel

Configure Channel 0 for DF1 Point-to-Point

DF1 slave 10-9 DF1 master 10-12 User mode

If You Want to Use

Serial Settings

Option Settings

DF1 Enqs

Configure Channel 0 as a Slave Station

Select Enabled or Disabled

Option is enabled

To get status information for that channel

Error checking. CRC is more complete checking

Select one of the following

Driver

Station address

RTS send delay Amount of time that elapses

Signal and the beginning

RTS signal

Message ACK timeout Amount of time you want

Configure Channel 0 as a Master Station

10-12Communicating with Devices on a Serial Link

Enter a valid value RTS send delay

Octal

Retried before being declared

This time allows the modem to

Polling Settings

Master message

If you want the master station to

Transmit Message transmit

Between Station Polls

Default size is 64 words

Default size is 18 words

Remote stations

Priority poll file

Contains this Information

Being polled, etc

New remote station is polled

Word 2 through word

Configure Channel 0 for User Mode Ascii Protocol

Remote mode change

10-18Communicating with Devices on a Serial Link

File containing the channel’s

10-19

XON/XOFF

Enable

Disable

If You Want To Select

Remotely

10-22Communicating with Devices on a Serial Link

Using the System Mode Status Display

Monitoring Channel 0 Status

DCD recover

High

Messages sent

Device

Using the User Mode Ascii Status Display

Modem Lines

Communicating with Devices on an Ethernet Network

Using This Chapter Media and Cabling

Configuring channel 2 for Ethernet communication

Manually Configuring Channel

Network Addressing

Assigning Your IP Address

11-2Communicating with Devices on an Ethernet Network

11-3

Ethernet Channel 2 Configuration Fields

With programming software if Bootp is enabled

Using Bootp to Enter Configuration Information

Network This field is required when you

Broadcast Address

Controller should respond

11-6Communicating with Devices on an Ethernet Network

Editing the Bootptab Configuration File

Based on this configuration, the Bootptab file looks like

11-8Communicating with Devices on an Ethernet Network

Using Broadcast Addressing

If Bootp is enabled, you can’t change any

Advanced Ethernet communications characteristics

Broadcast addressing 11-9 Subnet masks and gateways 11-11

C.dWhere a, b, c, d are between 0-255 decimal

If you change the default and need to reset it, type

Form

11-10Communicating with Devices on an Ethernet Network

Using Subnet Masks and Gateways

Using Bootp to configure Be sure Bootp is enabled 11-13

If You are Then See

11-12

Subnet Mask Controller’s subnet mask

Subnets

Enter an address of the following form

Local subnet

Personal computer Windows

Or HP 9000 or VAX computer

Server 130.151.194.xxx Ethernet TCP/IP network

130.151.132.1

Bootptab files that correspond to this example looks like

11-14Communicating with Devices on an Ethernet Network

Using Domain Name Service

Using the Embedded Web Server

11-16Communicating with Devices on an Ethernet Network

Diagnostic Information

11-18Communicating with Devices on an Ethernet Network

This Counter Totals

This Indicates

Application Memory

Session Table Connections

11-20Communicating with Devices on an Ethernet Network

11-21

Generating User Provided Web Pages

11-22Communicating with Devices on an Ethernet Network

Output Timer

Status Counter Control

11-24Communicating with Devices on an Ethernet Network

Input image word is I0 is b!ABDTR-I0/b

Time values in T40 are!ABDTR-T40

BCD

Importing User Page Files to the PLC-5 Controller

11-26Communicating with Devices on an Ethernet Network

11-27

11-28Communicating with Devices on an Ethernet Network

11-29

Following examples use this system configuration

Multihop Examples

11-31

11-32Communicating with Devices on an Ethernet Network

Communicating with ControlLogix Devices

Comparing Multihop and Non-Multihop Messages Over Ethernet

Interpreting Error Codes

Controller sets the .ER bit and enters an error code

Code Hexadecimal Description

Displayed on the data monitor screen

Interpreting Ethernet Status Data

F00A

Active screen

11-34Communicating with Devices on an Ethernet Network

Monitoring general Ethernet status

Status Field Bytes Displays the Number

11-36Communicating with Devices on an Ethernet Network

Monitoring Ethernet commands

Monitoring Ethernet replies

Personal Computer

Ethernet PLC-5 Performance Considerations

Performance Host to Ethernet PLC-5 Controller

PLC-5 Controller Typed Write Packet Size

11-38Communicating with Devices on an Ethernet Network

Using protected controllers 12-6

Protecting Your Programs

12-4

File Assigning a privilege class to a node 12-4

Node privileges override the default privilege class

Channel

Structure

Defining Privilege Classes

Will be appropriate for a particular application

12-4Protecting Your Programs

Assigning a Privilege Class to a Node

Assigning a Privilege Class to a Channel or Offline File

12-5

Page

Programming Considerations

Forcing

Forcing Inputs and Outputs

13-11

13-2Programming Considerations

Extended Forcing

Forcing SFC Transitions

That you include in the extended force configuration

Do not use BTR data tables files to store

Non-block-transfer data. All non-block-transfer data

Table as read data will be forced to zero during

Enabled 003 ms Disabled 0015 ms

Increased Program Scan Time

Force Privileges

13-4Programming Considerations

Using Protected Controllers

Setting Up and Using Extended Forcing

With the Programming Software

Package

Select Which Group of Data You Want to Force

13-6Programming Considerations

Select all of data file N11

BTR #2 and ending at the end of BTR #4

Forces Must be of Type B, A, N, or D

Enable or Disable the Forces

Using Extended Forcing with Time-Critical Applications

Radix Force Screen Display

Binary

Enable the BTW

OTL

Using Special Programming Routines

13-10Programming Considerations

Deciding When to Use Special Routines

Priority Scheduling for Interrupts and MCPs

Program Execution States

13-12Programming Considerations

Program would be executing if it were of a higher priority

An MCP, STI, PII Does the program fault?

Rescheduling Operation

13-14Programming Considerations

I012

Program can be

Interrupted

Power-up routines Fault routines

Defining and Programming Interrupt Routines

Page

Preparing Power-Up Routines

Setting Power-Up Protection

If S26/1 is After power loss, the controller

Set

Defining a Controller Power-Up Procedure

Portion of the fault routine associated with a particular

Fault or power-up condition

Allowing or Inhibiting Startup

Use this Bit

15..............0

Page

Preparing Fault Routines

Responses to a Major Fault

Understanding the Fault Routine Concept

For Information About See

Faults

Understanding

General

It Sets

Fault in a Remote I/O Chassis

Preparing Fault Routines

15-4Preparing Fault Routines

Remote inputs inactive

Here are two programming methods you can use

Inputs

15-5

Programming a Fault Routine

Avoiding Multiple Watchdog Faults

To fault mode without completing the fault routine

If You Encounter Then

Setting an Alarm

Clearing a Major Fault

Fault. Be sure to examine the fault bit and correct

Cause of the fault before clearing it

Example of Comparing a Major Fault Code with a Reference

If the Fault Routine Then the Controller

Then faults

15-8Preparing Fault Routines

Changing the Fault Routine from Ladder Logic

Using Ladder Logic to Recover from a Fault

Ways to Recover from a Rack Fault Method Description

Monitoring Faults

Block-Transfers in Fault Routines

Testing a Fault Routine

You can Monitor Description

Monitoring Major/Minor Faults and Fault Codes

Interpreting Major Faults

Interpreting Minor Faults

For a description of the major faults S11, see Appendix B

PLC-5/60, -5/60L, -5/80, 5/80E

Monitoring Status Bits

PLC-5/11, -5/20, 5/20E PLC-5/30 PLC-5/40, -5/40L, 5/40E

Page

Selecting Main Control Programs

Using Main Control Programs

Consider Using this Technique If You are

16-2Using Main Control Programs

MCP

Configuring MCPs

An I/O update

Using Main Control Programs

If the MCP is a Following Occurs

This Field Do the Following Status File

Monitoring MCPs

Page

Writing STI Ladder Logic

Using Selectable Timed Interrupts

Using a Selectable Timed Interrupt

17-2Using Selectable Timed Interrupts

Control R60 Length Position Mode

STI Application Example

Block-Transfers in Selectable Timed Interrupts STIs

Defining a Selectable Timed Interrupt

Do the Following Status File

STI. If you disable the STI write a 0 to S31,

Monitoring Selectable Timed Interrupts

Controller uses the value in S30 to determine how often to

Check for a non-zero value in S31

Using Processor Input Interrupts

Using a Processor Input Interrupt

Using a processor input interrupt

18-1

Mode Description

Writing PII Ladder Logic

PII Application Examples

Two ways that you can use a PII program

Counter C40 Preset 100 Accum

Block-Transfers in Processor Input Interrupts PIIs

Output image bit remains set until the next count

C40.CU

18-4Using Processor Input Interrupts

Design Considerations

Defining a Controller Input Interrupt

Monitoring Controller Input Interrupts

This PII Field Stores Address

System Specifications

Controller Specifications

Memory and Channel Specifications

Controller Maximum

Maximum Maximum Number of I/O Cat. No

Any Mix

PLC-5/60 64 K2 Any mix or

Compatible PLC-5/60L 64 K2 Any mix or

Compatible Extended Local I/O PLC-5/80 100 K3 Any mix or

Compatible PLC-5/80E 100 K3 Any mix or

Battery Specifications

Eeprom Compatibility

Available

Eeprom compatibility is related to

Area Description

6System Specifications Publication 1785-UM012D-EN-P July

Processor Status File

S0 S2

This Word Stores Arithmetic flags

Step in an SFC

2Processor Status File

S2Switch setting information

This Word Stores

S3-10

S11

S12

This word stores the following fault codes

This Fault Code Indicates this Fault Fault Is

Error using SFR. This error occurs if

Non-recoverable. The fault

You jumped to an invalid non-ladder file

For instruction with missing NXT

Publication 1785-UM012D-EN-P July

8Processor Status File

Recoverable

Service

S13-S24

S26-S35

RUN

S36-S78

S79-S127

Maximizing System Performance

Using This Chapter Program Scan

Using program control instructions

Effects of Different Input States on Logic Scan Time

Effects of False Logic versus True Logic on Logic Scan Time

Other instructions may have a greater or lesser effect

If I000/00 is Then the Rung is

Effects of Using Interrupts on Logic Scan Time

Effects of Different Instructions on Logic Scan Time

Editing While in Remote Run Mode

Effects of Housekeeping Time

Online editing times for ladder programs are as follows

For this Editing Operation This Type Times are Program

Calculating Throughput

Using Global Status Flag Files

Card Backplane + Card Remote I/O Processor Delay Scan Time

6Maximizing System Performance

Input and Output Modules Delay

Remote I/O Scan Time

Communication Rate

Number of Rack Entries

Time Rate kbps

57.6 115.2 230.4

8Maximizing System Performance

Block-Transfers

Ms/Word Overhead ms Rate kbps

Kbps Rack Words words No BTs

Calculating Worst-Case Remote I/O Scan Time

Optimizing Remote I/O Scan Time

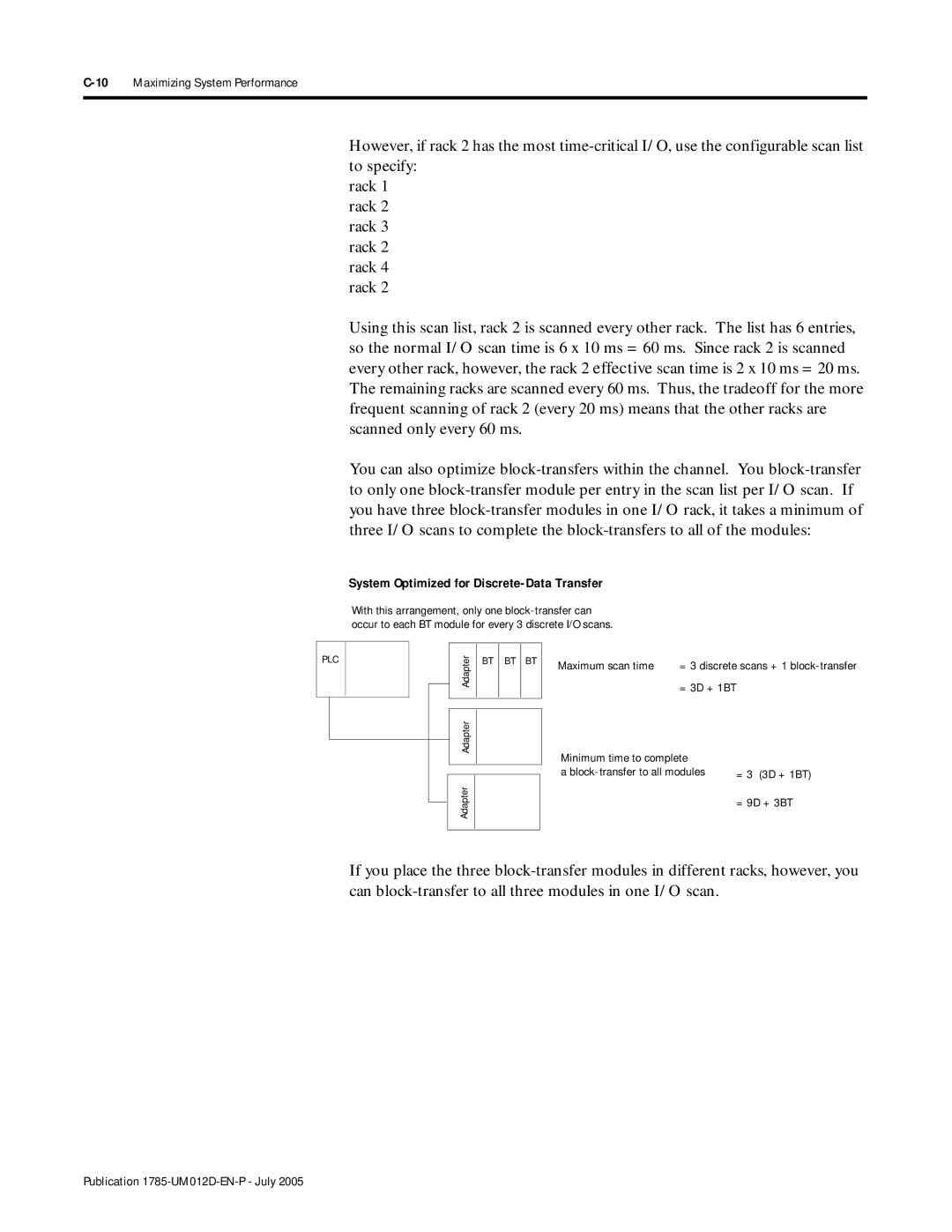

10Maximizing System Performance

Maximum scan time

Update Image

Controller Time

Minimum time to complete

Block-transfer to all modules = 1 3D + 3BT = 3D + 3BT

Variable Value

Example Calculation

Worst-case controller time is

Effect of Inserting Ladder Rungs at 56K-word Limit

Down at the End of a Rungs Program File

No impact 50 ms/Kwords

Remote block-transfers

Using JMP/LBL Instructions

Using FOR/NXT Instructions

Instruction Consideration

JMP

Timing and memory requirements for file program control,

Instruction Set Quick Reference

If You Want to Read About

Relay Instructions

Timer Instructions

Instruction Description

TON

TOF

Counter Instructions

RTO

RES

CTU

Compare Instructions

CTD

LIM

MEQ

CMP

EQU

GEQ

GRT

Compute Instructions

CPT

ACS

ADD

AVE

ASN

ATN

DIV

CLR

COS

Multiply

MUL

10Instruction Set Quick Reference

SourceN70

SQR

NEG

SIN

SRT

STD

To the power of Y XPY

Subtract

SUB

Tangent

Logical Instructions

DEG

Conversion Instructions

Convert to Degrees

Bit Modify and Move Instructions

RAD

MOV

MVM

File Instructions

BTD

FAL

FSC

File Copy

COP

File Fill

FLL

DDT

Diagnostic Instructions

FBC

Shift Register Instructions

BSL

BSR

FFL

Sequencer Instructions

LFL

LFU

SQI

Program Control Instructions

JSR

SBR

RET

AFI

SFR

EOT

UID

UIE

Process Control, Message Instructions

Block Transfer Instructions

BTR

Requeued

BTW

Identifies the number of words in the transfer. a

ACB

Ascii Instructions

ABL

AEX

AIC

AHL

ARD

ASC

ASR

AWA

AWT

Floating Point True False

Bit and Word Instructions

Category Code Title

True False

TOD

FRD

LOG

File, Program Control, and Ascii Instructions

Category Code Title Time ∝s Words Integer Floating Point

Category Code Title Time ∝s Words

END

ISA

AHL ¡

ACI

ACN

Ascii AIC

ASCII2 AWA

Write with append

Write

38Instruction Set Quick Reference

Controller’s DH+ address

Switch Setting Reference

For this Switch Setting

Channel 1A

Controller Switches

Switch

Front Processor 12 3 4 5 6 7 8 9 Side View

To Specify Set Switches

RS-232C Off RS-422A RS-423

PLC-5 Controller in the I/O Chassis

4Switch Setting Reference

Chassis Backplane

Always Off Switch Last State

AS or -ASB Switches Addressing Pressed

Off Slot At top on closed Pressed

Slot At bottom OFF open Not allowed

Chassis Configuration Plug

6Switch Setting Reference

Set Y when you install

Power supply module

First I/O Group Number

First I/O Group Number Rack Number see below see next

Kbps

Link Response

8Switch Setting Reference

Rack

ALX Switch SW1

Extended-Local I/O Adapter Module

SW-2 Not Used

First I/O Group Number Rack Number

ALX Configuration Plug

If You are Using But Not

On the 2 upper pins

Modules and any Addressing method

Troubleshooting

For Information About Troubleshooting Go to

Entering run mode

Unexpected PLC-5 controller operation when

General Problems

Indicator Color Description

PLC-5 Controller

Recommended Action

Force

Comm

DH+

Controller Communication Channel Troubleshooting

Color Channel Mode Description

Extended-Local I/O Troubleshooting

Ethernet Status Indicator

Indicator Color Channel Mode Description

Indicator Color Description Probable Cause

Remote I/O System

Ethernet Transmit LED

Indicators are still blinking, check

Mode adapter to

Troubleshooting F-7

Adapter module

Off Chassis fault Problem exists between

Problem resulting from high noise.2

Line fault Off Module not Power supply fault

Configuration

Fault Rack

Extended-Local I/O System

Unexpected Operation when Entering Run Mode

Instructions with Unique Prescan Operations

This Executes These Actions During Prescan Instruction

AWT AWA ACB ABL AHL BTR

Suggested Action

MSG

12Troubleshooting Publication 1785-UM012D-EN-P July

Shading indicates that the pin is reserved

Cable Reference

Pin RS-232C RS-422A RS-423

Serial Cable Pin Assignments

2Cable Reference

Connecting Diagrams

Terminal 1784-CAK KE Series B 1770-CD

4Cable Reference

Terminal Cable #2 1770-KF2 1784-CP5 1784-CP7

Cable 1784-CAK Connects 1785-KE to WorkstationT

Programming Cable Specifications

For Use this Cable See

6Cable Reference

Shield

Blue Controller Pin D-Shell Workstation

Clear Shield Blue Pin

Position Terminal connector Blue Shield Clear

Twinax Cable

Pin D-Shell Female

10 ft

Cable 1784-PCM5 Controller to Workstation using a 1784-PCMK

8Cable Reference

Pin D-Shell Workstation Female Controller DH+ 9-pin

Controller Male

Table below describes Allen-Bradley transceivers

Catalog Number Description

Cable Reference G-9

Ethernet cable Transceivers and transceiver cables

5810-TC15/A

5810-TAS/A kit

5810-TAM/A kit

5810-TBS/A kit

1784CP2 9-21784CP3

Numerics

1771KRF 9-21771SN

IP address 11-7using

Using 6200 software 11-3using Bootp

Extendedlocal I/O scanner configuration

Serial 10-6troubleshooting F-4

Connections Ethernet G-9

Data transfer 6-11blocktransfer

Token passing 9-13transmission rate 9-4troubleshooting F-4

Power supplies 3-6discrete data transfer

Program state 13-12extendedlocal I/O

Addressing 11-2advanced functions

Clearing 6-10,8-11global status bits 15-11,15-13

Gapping 4-12gateways

Communication F-4Ethernet F-5,F-6

Prescan timing F-10program control D-22

Interrupts C-3scheduling

Mnemonic 4-18specifying

Passwords 12-2performance

Chassis dimensions 3-5power supply dimensions

Optimizing 4-22program files 4-15protection E-4

Multiple chassis status bits 15-11,15-13

Mounting dimensions 3-6powerup routines 13-10,13-11,14-1

Fault routines 15-6features

Recover from rack fault 15-10terminal connections G-5

Schemes 10-16techniques

Serial devices 10-1setting switches

Specifications A-1specifications A-1

Program files 4-15temperature

Performance 17-2program flow

Pointtopoint 10-3status

Token passing 9-13transceivers G-9troubleshooting

User interrupts 13-14user mode 10-2,10-18

Input states C-2instructions C-3

Influencing processor priorities

Index Publication 1785-UM012D-EN-P July

Completeness

Technical Accuracy

Clarity

Other Comments

Business Reply Mail

Other Comments

Page

Page

Page

Rockwell Automation Support

Installation Assistance

New Product Satisfaction Return