Bar Code Label Printer

Page

Iii

Contributors

Page

Contents

Testing the Printer

Inspecting the Printer Cleaning the Printer

About Troubleshooting and Repair

Contents Adjusting the Printer

Error Handling

Miscellaneous Problems Vii

Replacing the Lithium Battery

Printer Maintenance Manual

Replacing Printer Components

Viii

Functional Description of the 3600 Software A-14

Appendix

Page

Before You Begin

Safety Summary

Purpose of This Manual

Who Should Read This Manual?

Xii

For information about

How This Manual Is Organized

Refer to

Xiii

Terms

Terms and Conventions

Conventions

Convention Description

Additional Information

Page

General Information

Page

Overview of the 3600 Printer

Printer Specifications

Features

Dimensions no options installed

Electrical Requirements

Media Specifications

Printhead Specifications

Ribbon Specifications

Self-Strip Specifications

Fonts and Graphics

Communications

Character Sets

Memory

Configuration

Factory Default Settings

Printer Options

Memory Expansion

Parallel Interface

Coax Interface

Network Connectivity

Kanji/Katakana Character Support

Principal Functional Parts

Media post TTR supply hub TTR takeup hub

Basic Printer Setup and Operation

Over-Temperature

Front Panel Operation

Media or System Faults

Checking the Printer Configuration

Feed/Pause Pushbutton

Printer Condition

DIP Switch Settings

Connecting the Printer to a Computer

Using Third-Party Software

Using Label Debut

Printer Maintenance Manual Serial Port Settings

Parameter Settings Description

Using the Printer Command Set

Page

Preventive Maintenance

Page

Printer Component Maintenance Action and Interval

Preventive Maintenance Actions and Intervals

Inspecting the Printer

Cleaning the Printer

To remove the media cover

Removing the Media Cover

To clean the printhead

Cleaning the Printhead

Thermal Printhead

To clean the rollers and tear bar

Cleaning the Rollers and Tear Bar

To clean the media guides and media path

Cleaning the Media Guides and Media Path

To clean the pinch rollers

To clean the sensors

Cleaning the Label and Ribbon Sensors

Cleaning the Printer Covers

Testing and Adjusting

Page

Testing the Printer

Running Test and Service Mode at the Printer

Setting DIP Switches

To exit Test and Service mode

Tests

Test and Service Switch Settings

= OFF

Dot Increment Switch Settings

Printing Test Labels

Hardware Configuration

Print Quality

Printer Maintenance Manual Software Configuration

Pitch

Format

201

Printer Maintenance Manual Font

Command Code Test Description

Running Test and Service Mode From a Host Computer

To test host-to-printer communications

Testing Printer and Host Communications

Adjusting the Printer

To adjust the bias adjust screw

Adjusting the Print Bias for Print Quality

To adjust the print darkness control

Adjusting the Print Intensity

Adjusting the Printhead Adjustment Lever for Print Quality

To position the label mark sensor

Adjusting the Label Mark Sensor

To adjust the label mark sensor potentiometer sensitivity

To adjust the label gap sensor potentiometer

Adjusting the Label Gap Sensor

To adjust the label taken sensor

Adjusting the Label Taken Sensor

Aligning the Printer

To align the rollers

Aligning the Rollers

To align the printhead

Aligning the Printhead

Printhead alignment

To align the TTR supply hub

Aligning the TTR Supply Hub

Printer Maintenance Manual

Troubleshooting

Page

Troubleshooting Tips

About Troubleshooting and Repair

Where to Start

Repair

Troubleshooting Checklist

Syntax Errors

Error Handling

Parameter Errors

Image Overrun Errors

Invalid Numeric Character Errors

Insufficient Storage RAM Errors

Error Codes

Error Code Problem Solution

Troubleshooting Printer Errors

Printer Maintenance Manual Printer Errors

Symptom Possible Causes

Printer Operation Problems

Symptom Possible Causes Solution

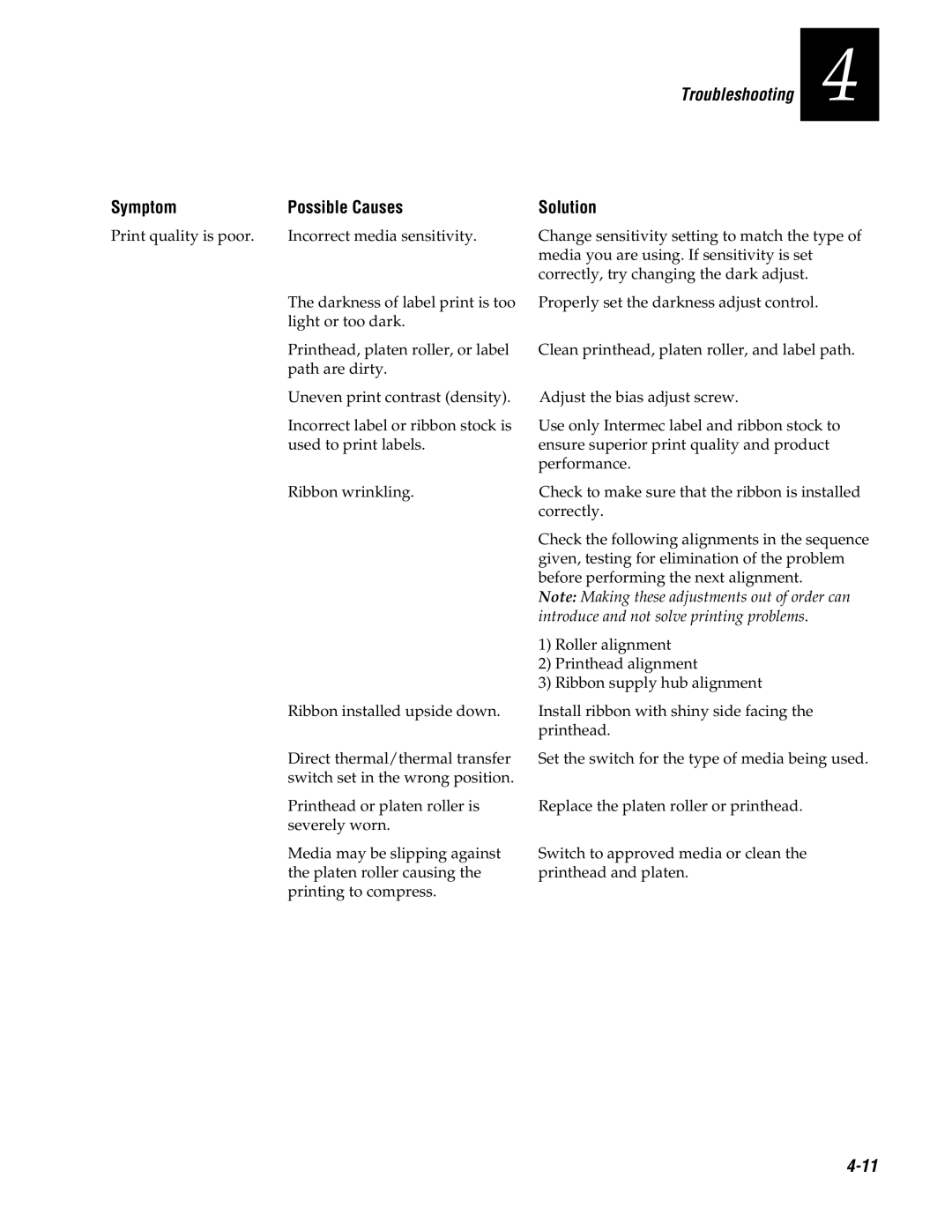

Print Quality Problems

Troubleshooting

Communications Problems

Environmental Problems

To check for communications problems

Electrostatic Discharge ESD

Electromagnetic and Radio Frequency Interference

Ground Loops Between Equipment

Inadequate Earth Ground

To troubleshoot environmental problems

AC Power Problems Surges, Sags, Spikes, Noise, and Outages

Miscellaneous Problems

Remove and Replace Procedures

Page

Replacing Printer Components

To replace the lithium battery

Replacing the Lithium Battery

Remove and Replace Procedures

Replacing the Printhead

To replace the printhead

Replacing the Bezel PCB

To replace the bezel PCB assembly

Bezel PCB assembly Yellow button cap

Replacing the Main PCB

To replace the main PCB assembly

To replace the Kanji/Katakana PCB

Replacing the Kanji/Katakana Option PCB

To replace the label mark sensor

Replacing the Label Mark Sensor

3600M.049

To replace the label taken sensor

Replacing the Label Taken Sensor

To replace the label gap sensor

Replacing the Label Gap Sensor

Upper media guide Label gap sensor

To remove the TTR drive roller and TTR drive gear/pulley

Replacing the TTR Drive Roller and Gear/Pulley

Washer Ring

To replace the TTR drive roller and TTR drive gear/pulley

Replacing the TTR Takeup Hub, Clutch/Pulley, and Belt

Remove and Replace Procedures

Replacing the TTR Supply Hub and Adjusting Plate

TTR

To remove the platen roller and platen roller gear

Replacing the Platen Roller and Gear

To replace the platen roller and platen roller gear

To replace the liner takeup hub and liner reverse gear

Replacing the Liner Drive and Takeup Components

Liner reverse gear Thin washer Snap ring

To replace the liner drive roller

Remove and Replace Procedures

Liner drive gear/pulley

To reassemble the liner drive and takeup components

To replace the stepper motor

Replacing the Stepper Motor

To replace the AC plug and input filter

Replacing the AC Plug/Input Filter

To replace the power switch/circuit breaker

Replacing the Power Switch/Circuit Breaker

To replace the transformer

Replacing the Transformer

Printer Maintenance Manual

PCB Drawings and Schematics

Page

PCB Drawings and Schematics

2/10

3/10

4/10

CAP,ALUM,RDL LEAD,50VMIN,100UF

CAP,AL,ELCTLT,R/L,63V,12000UF

CAP,S/M,CER,50WVDC,5%,10 PF

DIODE,S/M,TYPE BAS16

DIODE,S/M,TYPE MMBD301

IC,S/M,TYPE MC68332,MICPRCS

3600M.072

3600M.073

3600M.074

3600M.075

3600M.076

Page

Page

Replacement Parts

Page

Printer Spare Parts List

Replacement Parts

ID No

Part Number

PLATE, Front Cover

BATTERY, Lithium 3.6V, 1.75AH SCREW, THD Roll W/CONE

WASHER, Flat SST .327 X .50 X

Manuals

Page

3600M.091

3600M.092

3600M.093

3600M.094

3600M.095

114

127 125 128 129 130 131 132 133 134

Appendix

Page

Functional Description of the 3600 Mechanics

Functional Description of the 3600 Electronics

Power Supply

+5V

+40V

Battery

Power Fail Detection

Battery Life Calculations

Reset

Motor Driver

Chip Selects

Processor

Crystal

Interrupt Priority Levels

Eprom Access Time

RAM Access Time

Memory

Static RAM

Communications Interface

DIP Switches

Converter

Asic and I/O Option Interface

Front Panel Interface

Option Connector

Debug Interface

Chip Select Generation

Row Name Formula Min Max Margin Comment

Printer Maintenance Manual Timing

Timing Diagram

Functional Description of the 3600 Software

Band Buffering and Font Caching

Image Band Buffering

Image Band Example

Printer Maintenance Manual

Appendix a

Font Caching

Digital Thermal Compensation

Global Compensation

Appendix a Font Caching Flow Chart