J300 Series

Definitions and Symbols

Safety

Precautions

Page

Iii Pollution degree Aug

Revision History Table

Table of Contents

Installation

Safety Precautions

Inputoutput

Noise filter Fuse Good example Power supply

Input phase failure protection

Bad example

Control and operation

Maintenance, inspection and part replacement

Appendix

Earth leakage breaker Mgo

Megohm-meter

Turn on and OFF Good example

Supply Leading power factor capacitor

Earth LeakageSurge absorber breaker Power

Motor

General Caution

To be grounded or shielded wire

Inspection Upon Unpacking

Contents of Specifications Label

Names of Parts

Appearance and Names of Parts

Installation

Be sure to check the ambient temperature

Vent hole Cm or more

Precaution for installation and wiring

Wiring

Power supply

ELB

Wiring the Power Supply and Motor

L3 RB + T1 T2 T3 PE

Dynamic Braking Resistor Braking Units

Inverter At the site

Improper grounding Proper grounding Inverter

FM CM1 PLC P24 CM2 AL2 AL1 AL0

Wiring of Control Circuit Terminals

CM2 AL2 AL1 AL0

Page

Connection to the Programmable Controller

200V class

Wiring Equipment, Options EMI filter, etc

Standard equipment Power supply

Magnetic

Inverter

RB P

Terminal

Run signal 27 VDC Intelligent output signal

Free run input signal

Current frequency command

Common for frequency command Output

PLC

Control Circuit Terminals

Cosø=0.4 10 mA 30 VDC Resistor load

Abnormal, Power off

AL0-AL1 open

Contact rating 250 VAC Resistor load

Terminal Connection Diagram

Before Starting Operation

Operation

Page

Operating with digital operator

Running from external command

For sink type wiring

Test Run

Key to

Key and then press Press

Key to set Press

Key to Key to set Press

Contact b Contact a

Contact specification

Resetting Any one of A, B and C is possible

Func Function key Up key, Down key

Power Lamp Monitor LED display

STOP/RESET key

Operation of the Digital Operator

Key Description

Key is pressed, the extension function mode can be selected

Explanation of Screen Display

Transition of Each Code

Monitor mode

Output frequency

Digital Operator Initialization List

Screen display

Explanation of Modes

Monitor mode contents

Is displayed

10.00 to 100.00 to

Trip current

Trip cause

Setting

Function mode

Frequency

Direction

Running

Tion time 1 Manual torque boost

Accelera- tion time 1 Decelera

Run

Extension function

Motor receiving voltage setting

How to Delete Trip History Data ,

Extension function mode contents

Initial value Constant between 99.9 is set in units

Start frequency adjustment

Extension Function Code

Speed control response constant

Frequency upper, lower limiter

Multispeed setting

Extension Function Code Contents and display

Carrier frequency setting

Frequency command sampling frequency setting

100 150

Setting method 20% 120%

Motor poles setting for motor speed monitor

Initial value Func

Same as A26

Setting end

Initial value Setting method

400 External frequency

External

Operation will be stopped

Inverter requiring an external resistor

T1 + t2 + t3 100 Model 055, 075LF

Terminal connection example

Output full-scale value

Current monitor

Torque monitor 200% of the rated torque

Only optionally set frequency

Frequency arrival signal output method

At the time of constant

Speed arrival

Swfw

Swjg

Maximum frequency

Base frequency setting

Frequency at the start of running

PID

Auto tuning setting

This function is valid when 0 is set for Setting method

Motor data selection

Ro-T- option selection

Unusable

Input

Terminal Setting

Extension Function Code Function name

Frequency arrival signal

Signal during running Setting method is the same

Overtorque signal Note As that of the input terminals

Input

Protection Functions

Other display

Error Messages and Diagnosis

Troubleshooting

BRD%ED

Ground fault on

Display on

Symptom

Check Countermeasure

Appropriate value

Trouble shooting

HRW-OJ

Page

Insulation resistance tests, withstand voltage tests

Maintenance and Inspection

Maintenance and Inspection Precautions

Inspection Items

Applied voltage Good example Time Megohm-meter

10-2

Bad example Time

Location Daily Periodic

10-3

Daily Inspection and Periodic Inspection 1/3

Instruments

Daily Inspection and Periodic Inspection 2/3

10-4

Daily Inspection and Periodic Inspection 3/3

Replacement

No blown out LEDs

Parts to be measured

Measurement Method for I/O Voltage, Current, and Power

Measurement method for output voltage

10-7

Common Standarsd Specifications

Standard Specifications

11-1

Description Input voltage Class Model Name Type

11-2

11-3

Individual Specification USA version J300

Connecting the remote operator

Functions When Using the Optional Remote Operator

12-1

12-2

Switch Model J300 series

Same as VWA, J100

12-3

Monitor mode

Term Lllllllll

12-4

12-5

Function mode

12-6

12-7

12-8

12-9

12-10

12-11

12-12

12-13

12-14

12-15

Other displays

For error contents, see

12-16

Fmax Fch

Forced rewriting Description Alarm

Value. Note that when Automatically rewritten

12-17

Remote operator, copy unit

Dimensions

12-18

12-19

Copy Unit Function

12-20

Data to be copied by the copy unit Precautions for copying

13-1

Service

Page

Precautions

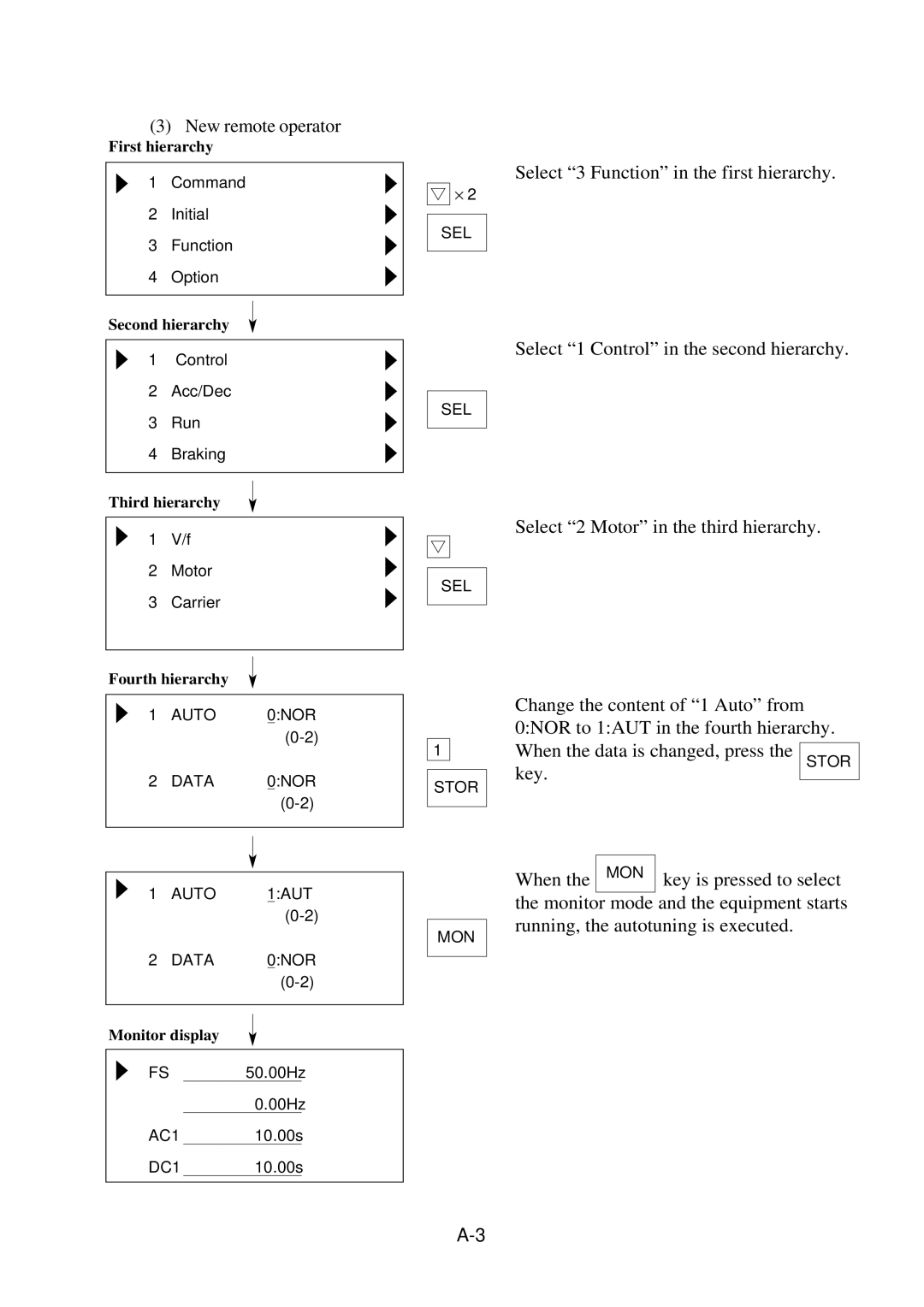

Autotuning start Setting method

Select 2 Motor in the third hierarchy

New remote operator

Select 3 Function in the first hierarchy

Select 1 Control in the second hierarchy

Tuning NG

Tuning END

Display in the failure state

Select Sensorless vector control by Control method

Running method by autotuning data

0VC to 4SLV in the fourth hierarchy

Change the content of 6 Mode from

When the data is changed, press Key

Select 1 V/f in the third hierarchy

Carrier

Energy conservation running Outline of the function

50% Range where the energy conservation is effective

Large load

Initial display

SPD

Precautions

Principle

Setting process

Digital operator Select Running mode selec Tion

STR Mode 2GOD

IPS Trip OFF

IPS Powr

Alarm

Time chart for retry mode

Digitaloperator

Commercial power source switching

Set TRM terminal mode

Function mode F-34

Elbc

Appendix 3 Capacitor Life Curve

Ambient Temperature Hours Operation/day Capacitor life year

Deceleration

Appendix 4 Acceleration/Deceleration Curve Constants

Curve

RU curve Acceleration

AUX

When V/f control is selected Function mode

When sensor-less vector control is selected Function mode

Operation conditions

Load varies

Operation conditions Phenomena Improvements Display, etc

Quickly varying load

Motor revolution varies when

AUX K 022.00 kW 005.50 kW Select the most approximate value

Select the motor capacity which is the most approxi

Mate to the total capacity of the motors used

For example, 7.5 kW, 5.5 kW, and 3.7 kW

Function name Second function setting

Appendix 6 Supplementaly Explanation of the Function Mode

HOP, HRW DOP, DRW

Monitor mode

HRW DRW

SET Selectrem

4RESET

Initreseton

1F-SET

3LINE Acclinel

Controlvc

1AUTO 0NOR

2DATA 0NOR

2FRS 1ZST Runfrs ZST

3LINE Decline L

4GAIN Decgain

2TIME

2LIMH

1LEVEL

2CONST1.0

1LIML

IN-TM4FRS

IN-TM1RS

IN-TM2AT

IN-TM3JG

1RYA 3RUN

1BAUD

2NUMBER1

0EVN

Appendix 8 PID Function

Wiring Sketch

PID Gain

Data Setting Method