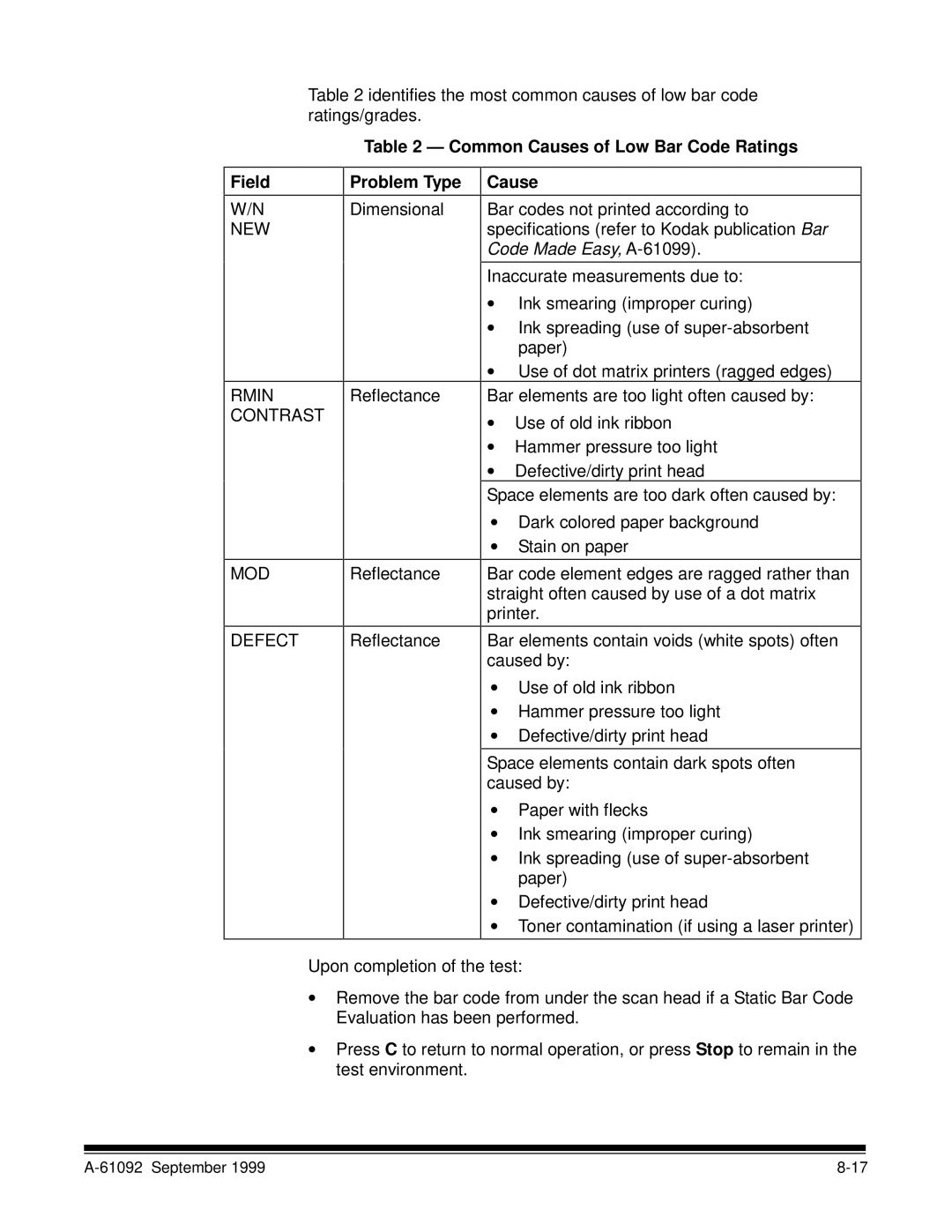

Table 2 identifies the most common causes of low bar code ratings/grades.

Table 2 — Common Causes of Low Bar Code Ratings

Field

W/N

NEW

RMIN CONTRAST

MOD

DEFECT

Problem Type

Dimensional

Reflectance

Reflectance

Reflectance

Cause

Bar codes not printed according to specifications (refer to Kodak publication Bar Code Made Easy,

Inaccurate measurements due to:

∙Ink smearing (improper curing)

∙Ink spreading (use of

∙Use of dot matrix printers (ragged edges) Bar elements are too light often caused by:

∙Use of old ink ribbon

∙Hammer pressure too light

∙Defective/dirty print head

Space elements are too dark often caused by:

∙Dark colored paper background

∙Stain on paper

Bar code element edges are ragged rather than straight often caused by use of a dot matrix printer.

Bar elements contain voids (white spots) often caused by:

∙Use of old ink ribbon

∙Hammer pressure too light

∙Defective/dirty print head

Space elements contain dark spots often caused by:

∙Paper with flecks

∙Ink smearing (improper curing)

∙Ink spreading (use of

∙Defective/dirty print head

∙Toner contamination (if using a laser printer)

Upon completion of the test:

∙Remove the bar code from under the scan head if a Static Bar Code Evaluation has been performed.

∙Press C to return to normal operation, or press Stop to remain in the test environment.

|