Return to Section TOC

Section TOC

Return to Master TOC

Master TOC

TROUBLESHOOTING & REPAIR

FEEDBACK INPUT TEST (continued)

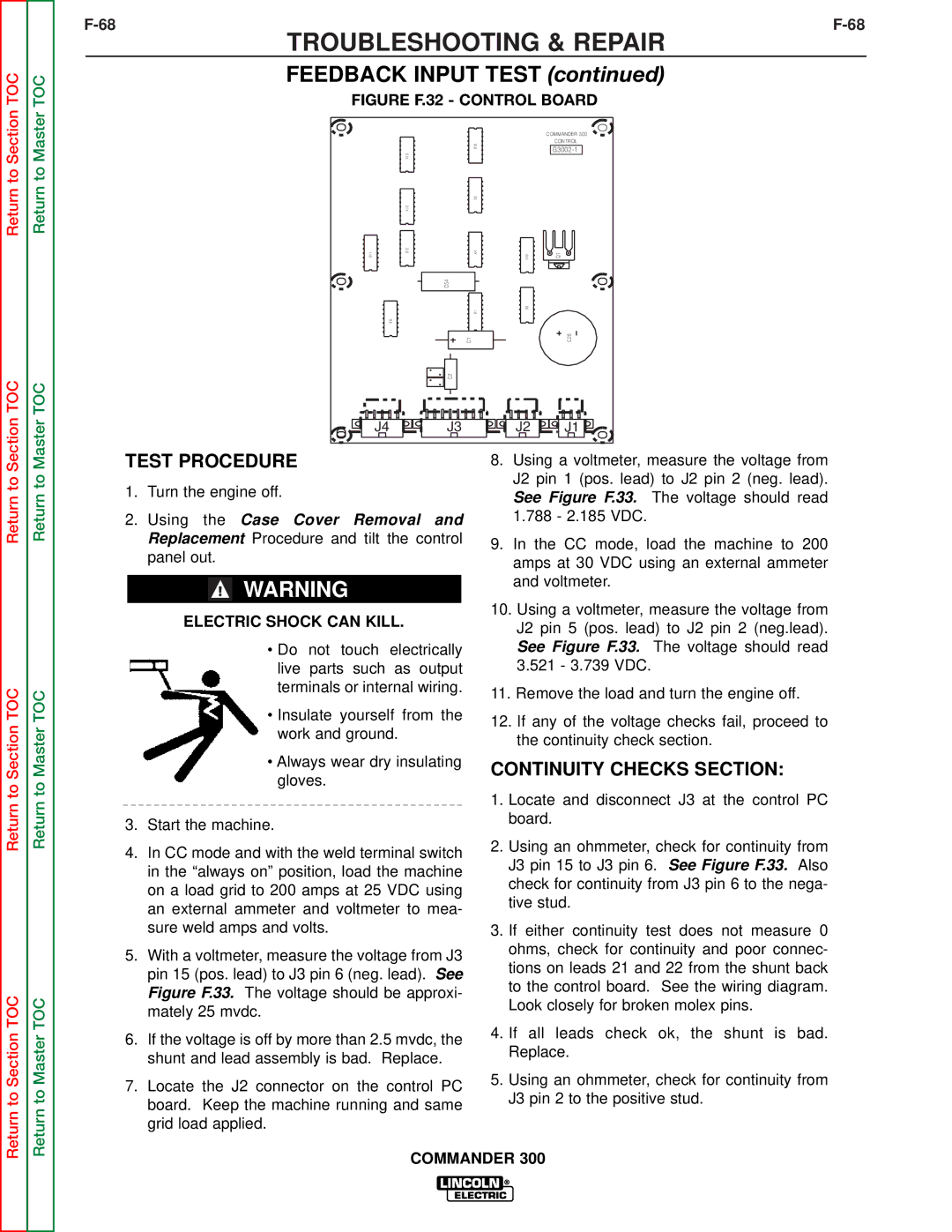

FIGURE F.32 - CONTROL BOARD

|

|

|

| COMMANDER 300 |

|

| X18 |

| CONTROL |

|

|

| ||

| X13 |

|

| |

|

|

|

| |

|

| X2 |

|

|

| X12 |

|

|

|

X11 | X10 | X4 | X19 | Q1 |

|

| C54 |

|

|

|

| X1 | X5 |

|

|

|

|

| |

| X8 |

|

|

|

|

| C1 |

| C25 |

|

| C2 |

|

|

| J4 | J3 | J2 | J1 |

Return to

Return to Section TOC

Return to Section TOC

Return to

Return to Master TOC

Return to Master TOC

TEST PROCEDURE

1.Turn the engine off.

2.Using the Case Cover Removal and Replacement Procedure and tilt the control panel out.

WARNING

ELECTRIC SHOCK CAN KILL.

•Do not touch electrically live parts such as output terminals or internal wiring.

•Insulate yourself from the work and ground.

•Always wear dry insulating gloves.

3.Start the machine.

4.In CC mode and with the weld terminal switch in the “always on” position, load the machine on a load grid to 200 amps at 25 VDC using an external ammeter and voltmeter to mea- sure weld amps and volts.

5.With a voltmeter, measure the voltage from J3 pin 15 (pos. lead) to J3 pin 6 (neg. lead). See Figure F.33. The voltage should be approxi- mately 25 mvdc.

6.If the voltage is off by more than 2.5 mvdc, the shunt and lead assembly is bad. Replace.

7.Locate the J2 connector on the control PC board. Keep the machine running and same grid load applied.

8.Using a voltmeter, measure the voltage from J2 pin 1 (pos. lead) to J2 pin 2 (neg. lead). See Figure F.33. The voltage should read 1.788 - 2.185 VDC.

9.In the CC mode, load the machine to 200 amps at 30 VDC using an external ammeter and voltmeter.

10.Using a voltmeter, measure the voltage from J2 pin 5 (pos. lead) to J2 pin 2 (neg.lead). See Figure F.33. The voltage should read 3.521 - 3.739 VDC.

11.Remove the load and turn the engine off.

12.If any of the voltage checks fail, proceed to the continuity check section.

CONTINUITY CHECKS SECTION:

1.Locate and disconnect J3 at the control PC board.

2.Using an ohmmeter, check for continuity from J3 pin 15 to J3 pin 6. See Figure F.33. Also check for continuity from J3 pin 6 to the nega- tive stud.

3.If either continuity test does not measure 0 ohms, check for continuity and poor connec- tions on leads 21 and 22 from the shunt back to the control board. See the wiring diagram. Look closely for broken molex pins.

4.If all leads check ok, the shunt is bad. Replace.

5.Using an ohmmeter, check for continuity from J3 pin 2 to the positive stud.