OPERATION

Return to Section TOC

Return to Section TOC

Return to Section TOC

Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Master TOC

5.OIL PRESSURE GAUGE AND LIGHT

6.ENGINE ALTERNATOR AMMETER AND LIGHT

7.IDLER SWITCH: The switch has two positions as follows:

A)In the “HIGH” position, the engine runs at the high idle speed controlled by the governor.

B)In the “AUTO” position, the idler operates as fol- lows:

a.When switched from “HIGH” to “AUTO” or after starting the engine, the engine will operate at full speed for approximately 12 seconds and then go to low idle speed.

b.When the electrode touches the work or power is drawn for lights or tools (approxi- mately 100 watts minimum) the engine accelerates and operates at full speed.

c.When welding ceases or the AC power load is turned off, a fixed time delay of approxi- mately 12 seconds starts.

d.If the welding or AC power load is not restarted before the end of the time delay, the idler reduces the engine speed to low idle speed.

e.The engine will automatically return to high idle speed when the welding load or AC power load is reapplied.

IDLER OPERATIONAL EXCEPTIONS

When the WELDING TERMINALS switch is in the

“WELDING TERMINALS REMOTELY CONTROLLED” position the idler will operate as follows:

a. When the triggering device (Amptrol, Arc Start Switch, etc.) is pressed, the engine will acceler- ate and operate at full speed provided a welding load is applied within approximately 12 seconds.

b. If the triggering device remains pressed but no welding load is applied within approximately 12 seconds, the engine will return to low idle speed.

c. If the triggering device is released or welding ceases, the engine will return to low idle speed after approximately 12 seconds.

8.HOUR METER: The hour meter displays the total time that the engine has been running. This meter is a useful indicator for scheduling preventative maintenance.

WELDER CONTROLS (Items 9 through 14)

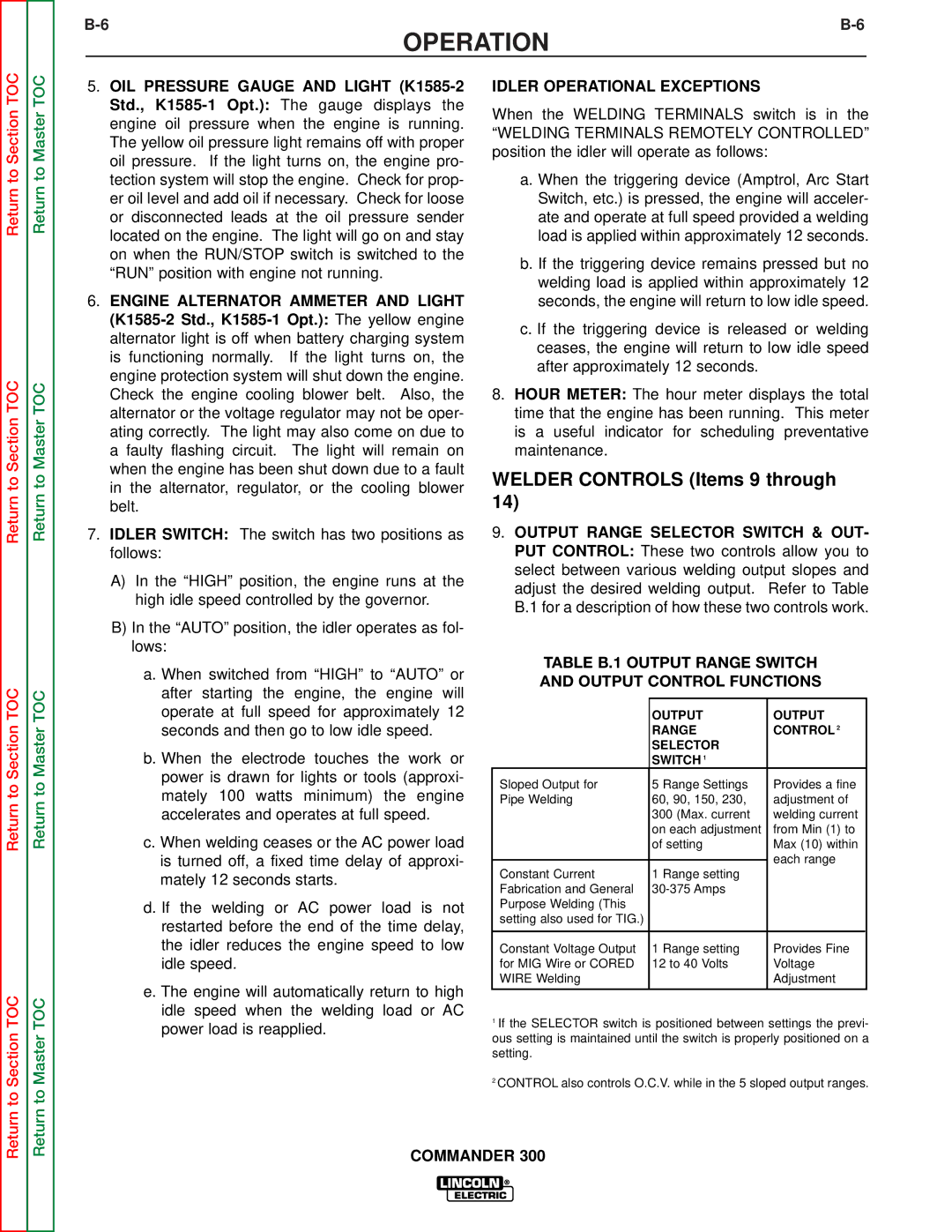

9.OUTPUT RANGE SELECTOR SWITCH & OUT- PUT CONTROL: These two controls allow you to select between various welding output slopes and adjust the desired welding output. Refer to Table B.1 for a description of how these two controls work.

TABLE B.1 OUTPUT RANGE SWITCH

AND OUTPUT CONTROL FUNCTIONS

|

|

|

|

|

| OUTPUT | OUTPUT |

|

| RANGE | CONTROL 2 |

|

| SELECTOR |

|

|

| SWITCH 1 |

|

| Sloped Output for | 5 Range Settings | Provides a fine |

| Pipe Welding | 60, 90, 150, 230, | adjustment of |

|

| 300 (Max. current | welding current |

|

| on each adjustment | from Min (1) to |

|

| of setting | Max (10) within |

|

|

| each range |

| Constant Current | 1 Range setting | |

|

| ||

| Fabrication and General |

| |

| Purpose Welding (This |

|

|

| setting also used for TIG.) |

|

|

|

|

|

|

| Constant Voltage Output | 1 Range setting | Provides Fine |

| for MIG Wire or CORED | 12 to 40 Volts | Voltage |

| WIRE Welding |

| Adjustment |

|

|

|

|

1If the SELECTOR switch is positioned between settings the previ- ous setting is maintained until the switch is properly positioned on a setting.

Return to

Return to

2CONTROL also controls O.C.V. while in the 5 sloped output ranges.