Section TOC

Master TOC

TROUBLESHOOTING & REPAIR

PWM OUTPUT TEST (continued)

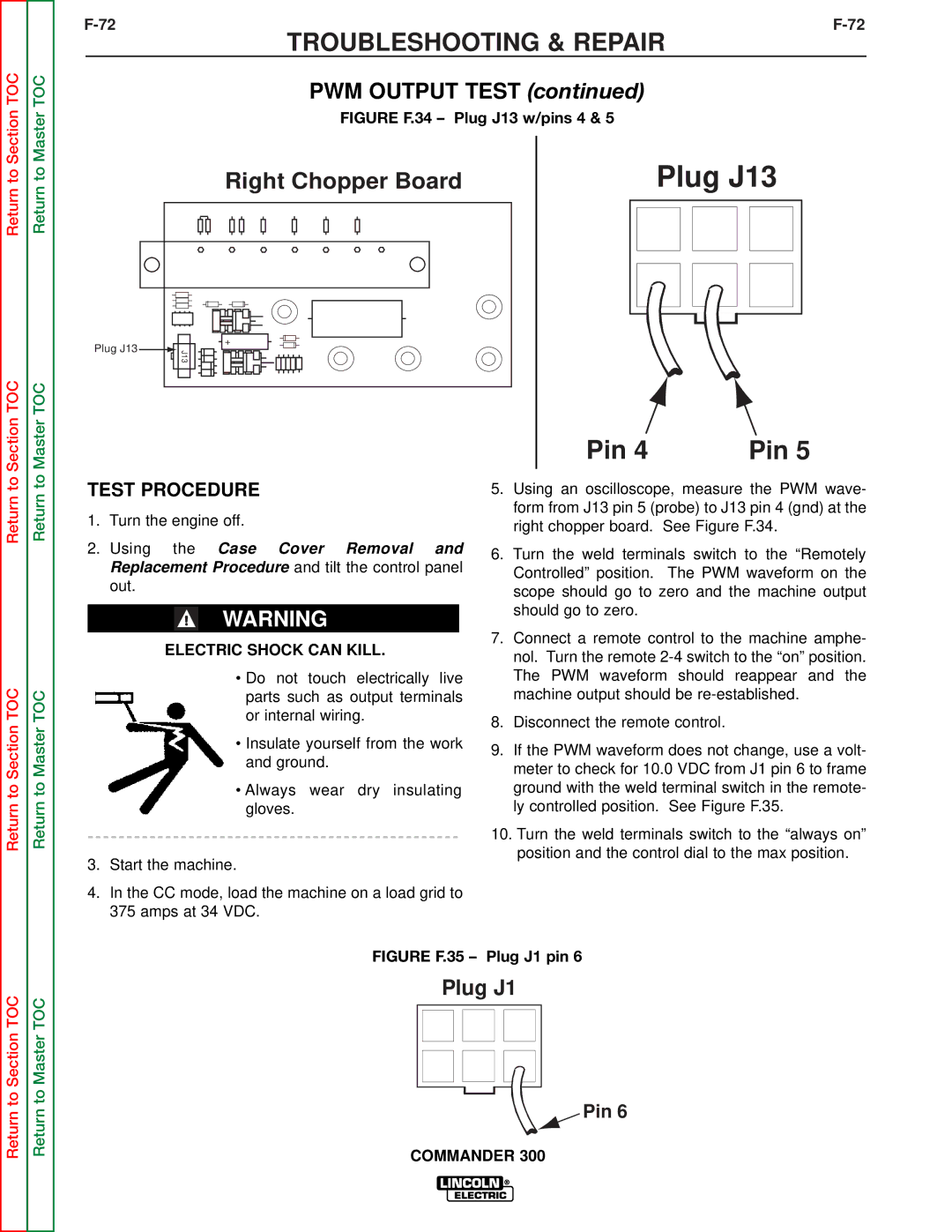

FIGURE F.34 – Plug J13 w/pins 4 & 5

Return to

Return to Section TOC

Return to Section TOC

Return to

Return to Master TOC

Return to Master TOC

Right Chopper Board

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plug J13 |

|

|

|

|

|

|

| + |

|

|

|

|

|

|

|

|

|

| J13 |

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TEST PROCEDURE

1.Turn the engine off.

2.Using the Case Cover Removal and Replacement Procedure and tilt the control panel out.

WARNING

ELECTRIC SHOCK CAN KILL.

•Do not touch electrically live parts such as output terminals or internal wiring.

•Insulate yourself from the work and ground.

•Always wear dry insulating gloves.

3.Start the machine.

4.In the CC mode, load the machine on a load grid to 375 amps at 34 VDC.

Plug J13

Pin 4 | Pin 5 |

5.Using an oscilloscope, measure the PWM wave- form from J13 pin 5 (probe) to J13 pin 4 (gnd) at the right chopper board. See Figure F.34.

6.Turn the weld terminals switch to the “Remotely Controlled” position. The PWM waveform on the scope should go to zero and the machine output should go to zero.

7.Connect a remote control to the machine amphe- nol. Turn the remote

8.Disconnect the remote control.

9.If the PWM waveform does not change, use a volt- meter to check for 10.0 VDC from J1 pin 6 to frame ground with the weld terminal switch in the remote- ly controlled position. See Figure F.35.

10.Turn the weld terminals switch to the “always on” position and the control dial to the max position.

Return to Section TOC

Return to Master TOC

FIGURE F.35 – Plug J1 pin 6

Plug J1

Pin 6