Return to Section TOC

Return to Section TOC

to Section TOC

Return to Master TOC

Return to Master TOC

to Master TOC

|

| OPERATION |

|

|

| ||||||

|

|

|

|

|

|

|

|

| |||

|

|

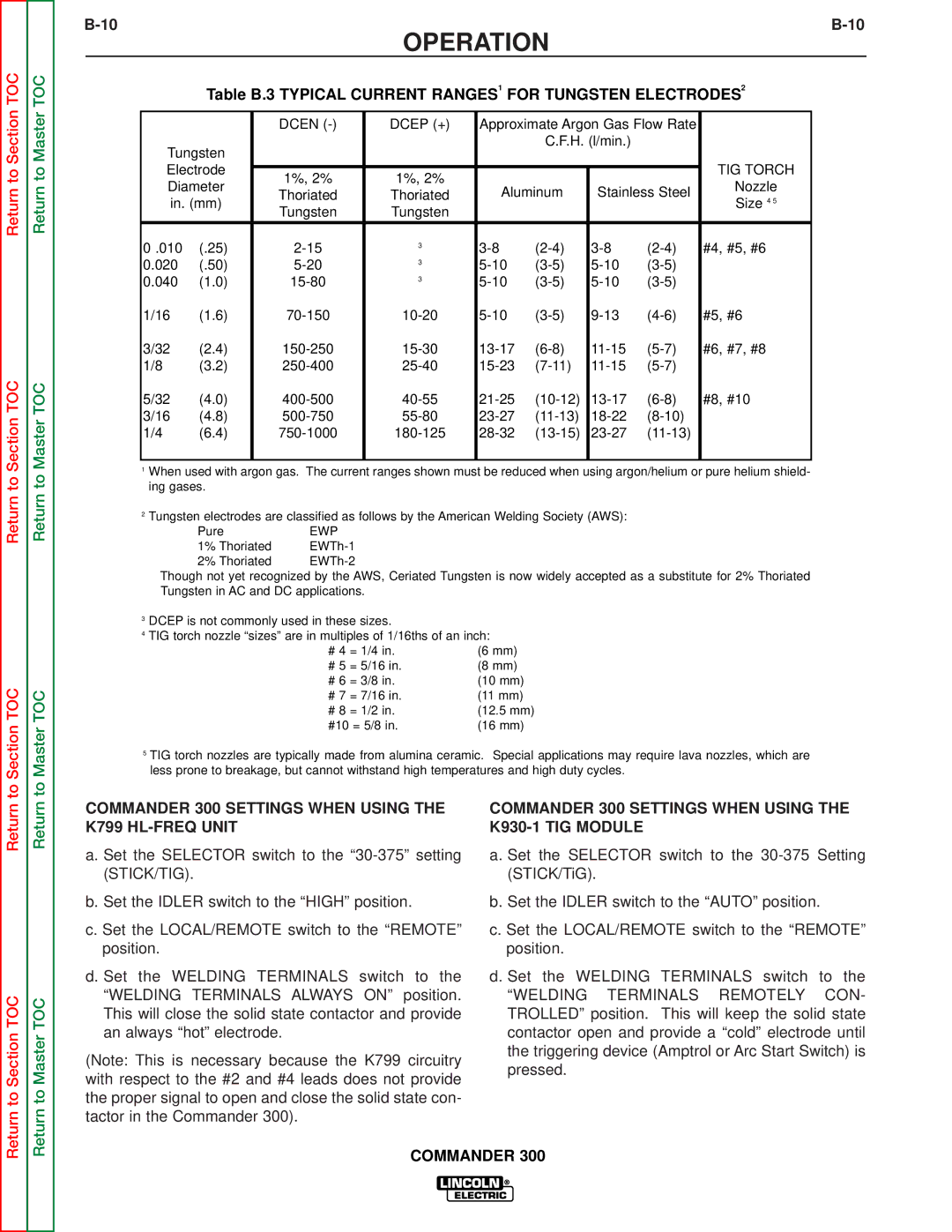

| Table B.3 TYPICAL CURRENT RANGES1 FOR TUNGSTEN ELECTRODES2 | ||||||||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

| DCEN | DCEP (+) | Approximate Argon Gas Flow Rate |

|

| |||

|

| Tungsten |

|

|

| C.F.H. (l/min.) |

|

|

| ||

|

|

|

|

|

|

|

|

|

| ||

|

| Electrode |

|

|

|

|

|

| TIG TORCH |

| |

|

| 1%, 2% | 1%, 2% |

|

|

|

|

| |||

|

| Diameter | Aluminum | Stainless Steel | Nozzle |

| |||||

|

| Thoriated | Thoriated |

| |||||||

|

| in. (mm) | Size 4 5 |

| |||||||

|

| Tungsten | Tungsten |

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |

|

| 0 .010 | (.25) | 3 | #4, #5, #6 |

| |||||

| 0.020 | (.50) | 3 |

|

| ||||||

| 0.040 | (1.0) | 3 |

|

| ||||||

|

|

|

|

|

|

|

|

|

|

| |

| 1/16 | (1.6) | #5, #6 |

| |||||||

| 3/32 | (2.4) | #6, #7, #8 |

| |||||||

| 1/8 | (3.2) |

|

| |||||||

| 5/32 | (4.0) | #8, #10 |

| |||||||

| 3/16 | (4.8) |

|

| |||||||

| 1/4 | (6.4) |

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

1When used with argon gas. The current ranges shown must be reduced when using argon/helium or pure helium shield- ing gases.

2Tungsten electrodes are classified as follows by the American Welding Society (AWS):

Pure | EWP |

1% Thoriated | |

2% Thoriated |

Though not yet recognized by the AWS, Ceriated Tungsten is now widely accepted as a substitute for 2% Thoriated Tungsten in AC and DC applications.

3DCEP is not commonly used in these sizes.

4TIG torch nozzle “sizes” are in multiples of 1/16ths of an inch:

# 4 = 1/4 in. | (6 mm) | |

# 5 | = 5/16 in. | (8 mm) |

# 6 | = 3/8 in. | (10 mm) |

# 7 | = 7/16 in. | (11 mm) |

# 8 | = 1/2 in. | (12.5 mm) |

#10 = 5/8 in. | (16 mm) | |

5TIG torch nozzles are typically made from alumina ceramic. Special applications may require lava nozzles, which are less prone to breakage, but cannot withstand high temperatures and high duty cycles.

Return

Return to Section TOC

Return

Return to Master TOC

COMMANDER 300 SETTINGS WHEN USING THE K799 HL-FREQ UNIT

a. Set the SELECTOR switch to the

b. Set the IDLER switch to the “HIGH” position.

c. Set the LOCAL/REMOTE switch to the “REMOTE” position.

d. Set the WELDING TERMINALS switch to the “WELDING TERMINALS ALWAYS ON” position. This will close the solid state contactor and provide an always “hot” electrode.

(Note: This is necessary because the K799 circuitry with respect to the #2 and #4 leads does not provide the proper signal to open and close the solid state con- tactor in the Commander 300).

COMMANDER 300 SETTINGS WHEN USING THE K930-1 TIG MODULE

a. Set the SELECTOR switch to the

b. Set the IDLER switch to the “AUTO” position.

c. Set the LOCAL/REMOTE switch to the “REMOTE” position.

d. Set the WELDING TERMINALS switch to the

“WELDING TERMINALS REMOTELY CON- TROLLED” position. This will keep the solid state contactor open and provide a “cold” electrode until the triggering device (Amptrol or Arc Start Switch) is pressed.