(a)Hopping from the 1st Tray

1 Hopping

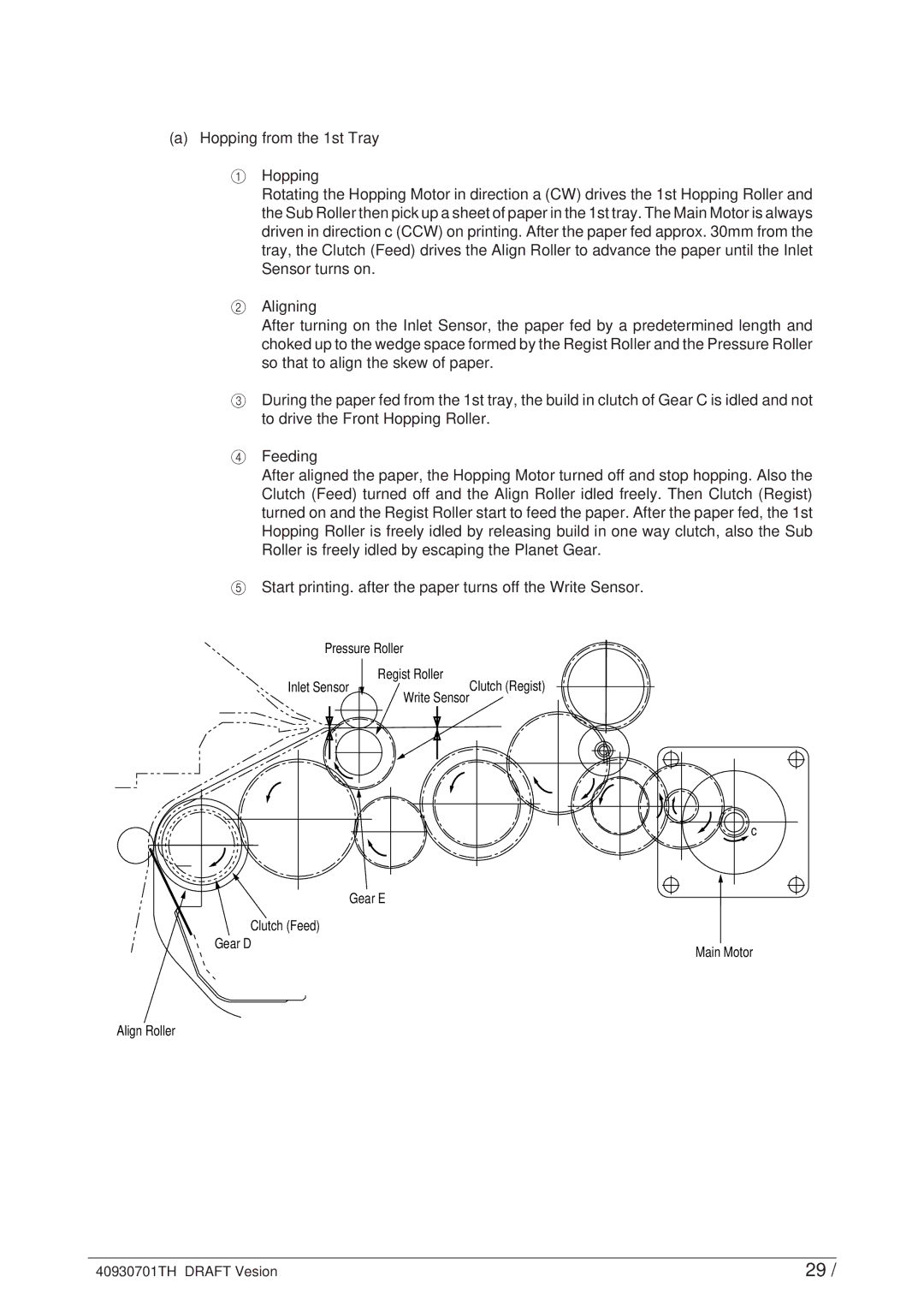

Rotating the Hopping Motor in direction a (CW) drives the 1st Hopping Roller and the Sub Roller then pick up a sheet of paper in the 1st tray. The Main Motor is always driven in direction c (CCW) on printing. After the paper fed approx. 30mm from the tray, the Clutch (Feed) drives the Align Roller to advance the paper until the Inlet Sensor turns on.

2Aligning

After turning on the Inlet Sensor, the paper fed by a predetermined length and choked up to the wedge space formed by the Regist Roller and the Pressure Roller so that to align the skew of paper.

3During the paper fed from the 1st tray, the build in clutch of Gear C is idled and not to drive the Front Hopping Roller.

4Feeding

After aligned the paper, the Hopping Motor turned off and stop hopping. Also the Clutch (Feed) turned off and the Align Roller idled freely. Then Clutch (Regist) turned on and the Regist Roller start to feed the paper. After the paper fed, the 1st Hopping Roller is freely idled by releasing build in one way clutch, also the Sub Roller is freely idled by escaping the Planet Gear.

5Start printing. after the paper turns off the Write Sensor.

Pressure Roller |

|

Regist Roller | Clutch (Regist) |

Inlet Sensor | |

Write Sensor |

|

![]() c

c

Gear E

Clutch (Feed)

Gear D

Align Roller

Main Motor

40930701TH DRAFT Vesion | 29 / |