Routine Care and Adjustments

Cleaning Procedures

Clean the Printhead and Platen Roller

You can minimize printhead wear and maintain print quality with regular preventive measures.

Over time, the movement of media/ribbon across the printhead wears through the protective ceramic coating, exposing and eventually damaging the print elements (dots). In order to avoid abrasion:

•Clean your printhead frequently and use

•Minimize printhead pressure and burn temperature settings by optimizing the balance between the two.

•Ensure that the thermal transfer ribbon is as wide or wider than the label media to prevent exposing the elements to the more abrasive label material.

For best results, perform the following cleaning procedure after changing every roll of ribbon. Inconsistent print quality, such as voids in the bar code or graphics, may indicate a dirty printhead.

Note • The printer can remain on while you are cleaning the printhead. In this way all label formats, images, and all temporary parameter settings stored in the printer’s internal memory are saved. In addition, keep the peel engaged while cleaning the platen roller (media must be unloaded to do this) to reduce the risk of bending the

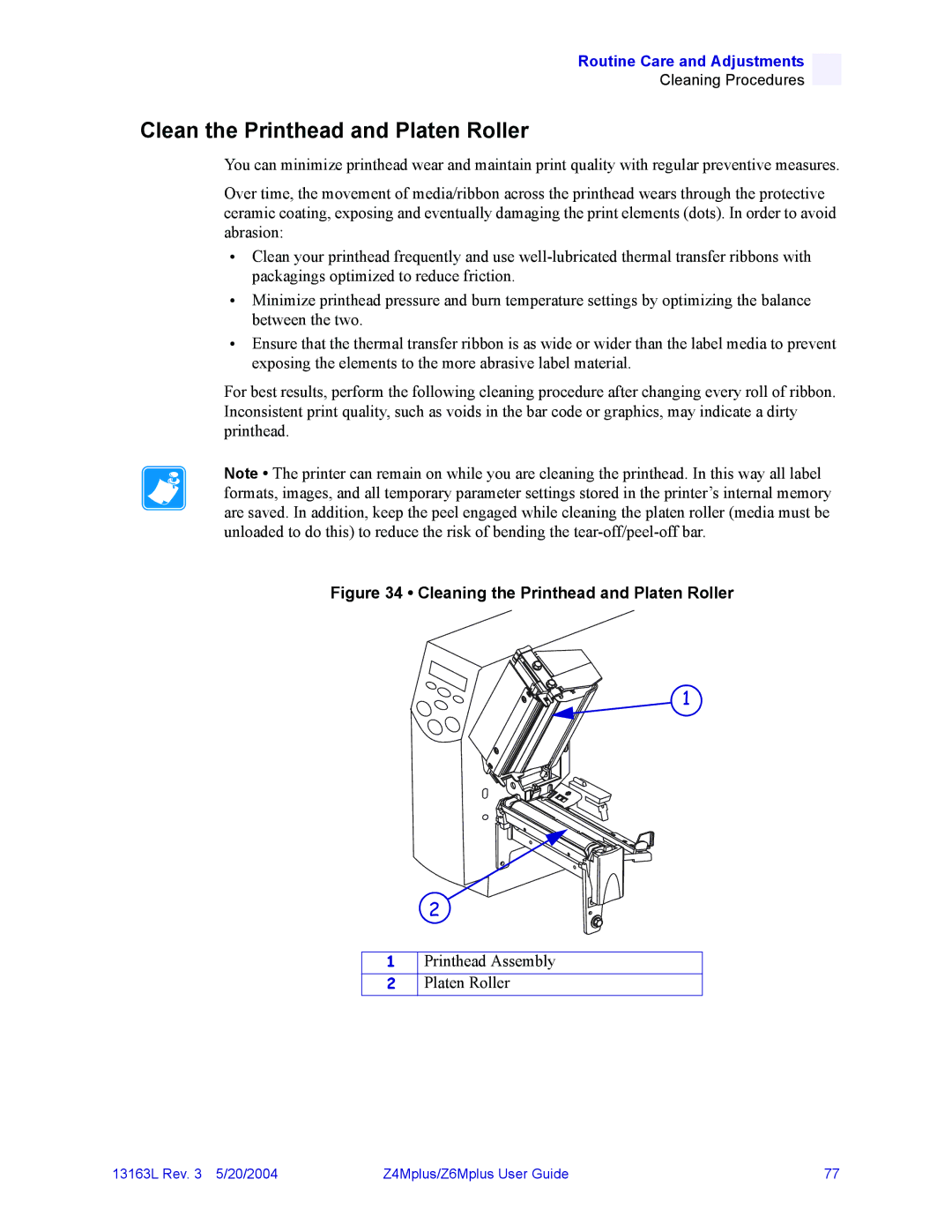

Figure 34 • Cleaning the Printhead and Platen Roller

1

2

1

2

Printhead Assembly Platen Roller

13163L Rev. 3 5/20/2004 | Z4Mplus/Z6Mplus User Guide | 77 |