7.3.7.Automatic Selection of Supplying Mat

When there are plural supplying mats of materials, the indicator has to control these gates. There are the following two method to control them.

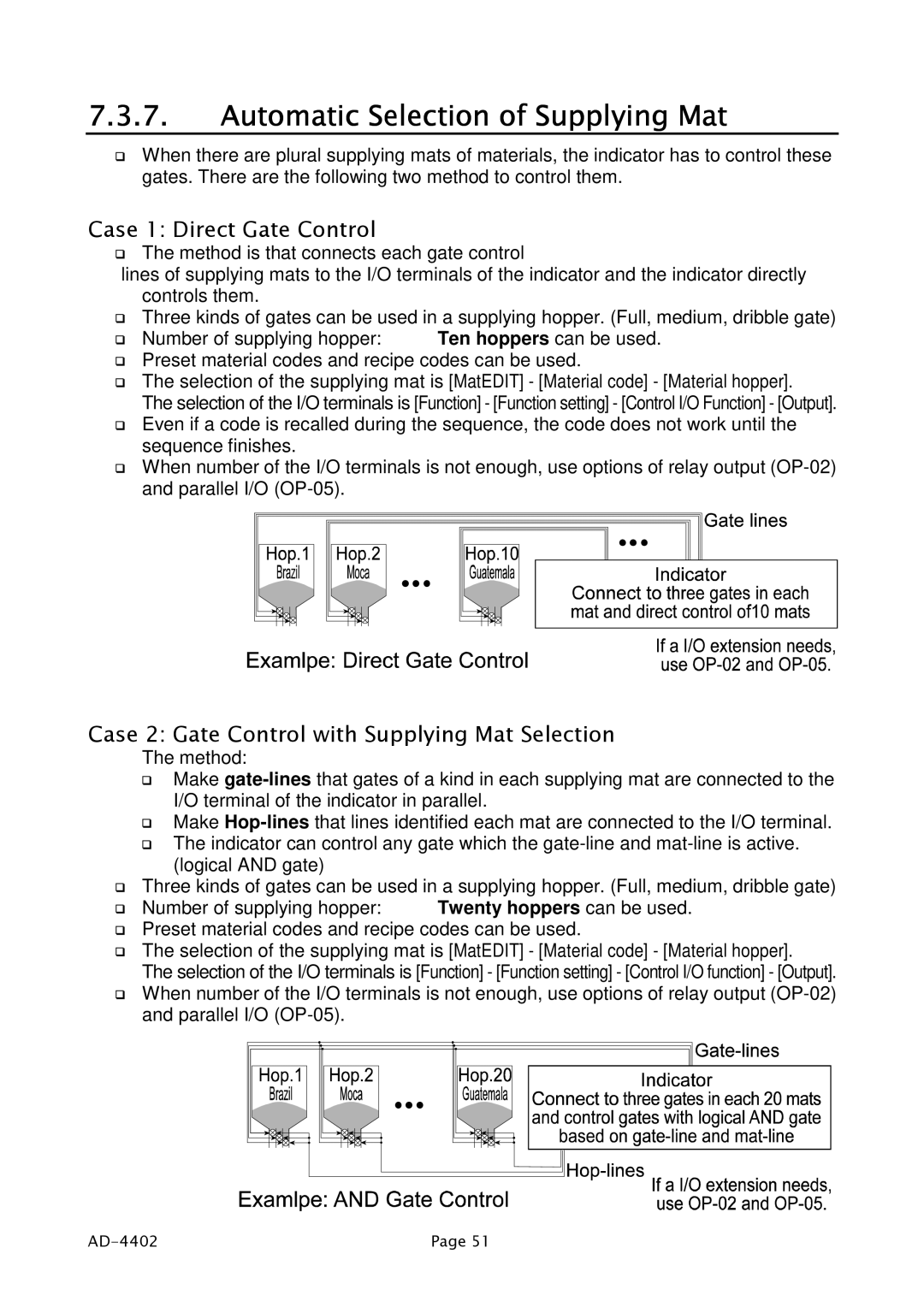

Case 1: Direct Gate Control

The method is that connects each gate control

lines of supplying mats to the I/O terminals of the indicator and the indicator directly controls them.

Three kinds of gates can be used in a supplying hopper. (Full, medium, dribble gate)

Number of supplying hopper: Ten hoppers can be used. Preset material codes and recipe codes can be used.

The selection of the supplying mat is [MatEDIT] - [Material code] - [Material hopper].

The selection of the I/O terminals is [Function] - [Function setting] - [Control I/O Function] - [Output]. Even if a code is recalled during the sequence, the code does not work until the sequence finishes.

When number of the I/O terminals is not enough, use options of relay output

Case 2: Gate Control with Supplying Mat Selection

The method:

Make

Make

The indicator can control any gate which the

Three kinds of gates can be used in a supplying hopper. (Full, medium, dribble gate)

|

| Number of supplying hopper: | Twenty hoppers can be used. |

|

| ||

|

| ||

|

| Preset material codes and recipe codes can be used. | |

| |||

|

| ||

|

| ||

The selection of the supplying mat is [MatEDIT] - [Material code] - [Material hopper].

The selection of the I/O terminals is [Function] - [Function setting] - [Control I/O function] - [Output]. When number of the I/O terminals is not enough, use options of relay output

| Page 51 |