Electronically Operated Ovens specifications

Alto-Shaam Electronically Operated Ovens represent a significant advancement in commercial kitchen technology, offering unmatched precision and versatility. Designed primarily for restaurants, hotels, and catering businesses, these ovens combine advanced cooking technologies with user-friendly features to enhance kitchen efficiency and food quality.One of the standout features of Alto-Shaam ovens is their customizable cooking modes. Operators can choose from various cooking methods, including convection, steam, and combination cooking, allowing them to prepare a wide range of dishes from perfectly roasted meats to delicate pastries. This versatility enables chefs to experiment and innovate, making it easier to craft unique menus that satisfy diverse dining preferences.

Another key characteristic of Alto-Shaam ovens is their use of Halo Heat technology. This innovative heating system provides consistent, even cooking through radiant heat, ensuring that food is cooked thoroughly without the need for excess moisture or fats. This not only enhances the flavor and texture of dishes but also promotes healthier cooking practices by reducing the amount of added oils or butter.

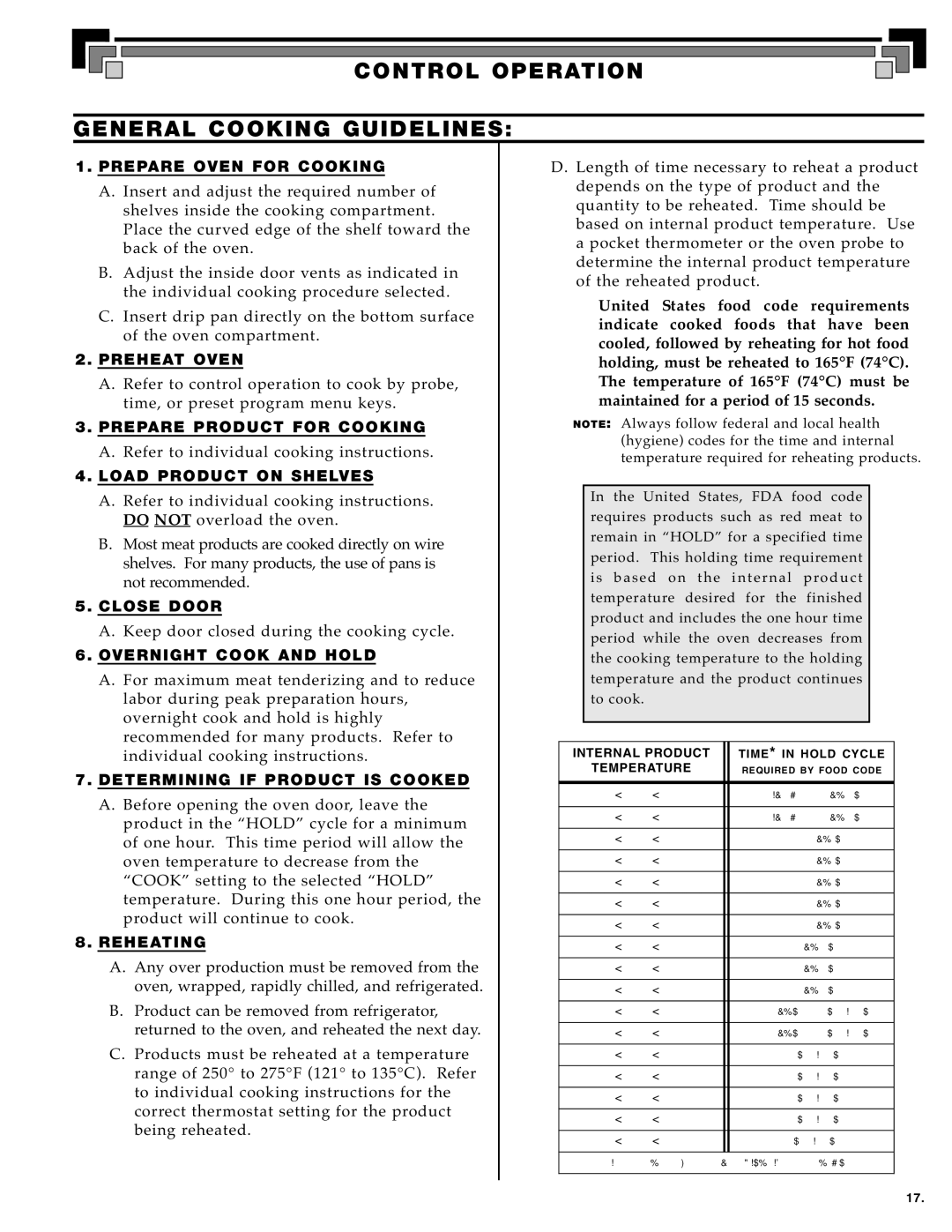

The ovens come equipped with a digital control panel that allows for precise temperature and time settings, ensuring that each dish is cooked to perfection. The intuitive interface makes it easy for kitchen staff to operate, reducing the chances of user error in a high-pressure environment. Additionally, many models include programmable recipes, enabling chefs to store their best creations for future use, which streamlines the cooking process and minimizes prep time.

Energy efficiency is another hallmark of Alto-Shaam ovens. Featuring insulation that minimizes heat loss, these ovens are designed to operate with lower energy consumption compared to traditional models. This not only leads to lower utility bills but also aligns with sustainable kitchen practices, making them an environmentally friendly choice for modern establishments.

Durability is crucial in a commercial kitchen, and Alto-Shaam ovens are built to last. Constructed from high-quality stainless steel, these ovens withstand the rigors of daily use while maintaining their aesthetic appeal. Regular maintenance is straightforward, which helps to prolong the life of the equipment.

In summary, Alto-Shaam Electronically Operated Ovens combine advanced cooking technologies with user-friendly features, making them an ideal choice for any commercial kitchen. With customizable cooking modes, Halo Heat technology, digital controls, energy efficiency, and robust construction, these ovens deliver exceptional performance and reliability, ensuring that chefs can consistently meet and exceed customer expectations.