Product Manual

Revision Date

To return equipment for service RMA Request

To order supplies and accessories

Iii

To obtain general information

1012581

Contents

Troubleshooting

Maintenance

Autoloader Operation

Viewing Autoloader Information

Write Once, Read Many Worm Capability

Specifications 119

133

Index 139

Viii

Configuring the Autoloader

Installing the Autoloader

Product Overview

Figure B-1Ultrium 3 Worm tape cartridge

Error Messages

Specifications

Table C-1Autoloader error messages

1Tape drive cartridge read/write compatibility

Xii

Maintenance, Troubleshooting, and Service

Installation

Xiii

About this Manual

Supplemental Information

Xiv

Magnum 1x7 LTO Autoloader

Ultrium Tape Drives

Conventions Used in this Manual

Will help you complete a procedure or avoid extra steps

Read text marked by the Important icon for information that

Avoid personal injury

Xvi

Product Overview

Autoloader Features

Front Panel Components

Autoloader Components

Back Panel Components

LED Color Status

3shows the autoloader’s internal components

Internal Components

Autoloader Components

1012581

Installing the Autoloader

1Label over shipping key

Completing the Unpacking Process

Obtaining Accessories and Equipment

LTO-3

Preparing for Installation

LTO-2

Autoloader and the outlet

Installing the Autoloader in a Rack

Sets of side support rails

#2 Phillips screwdriver Level Tape measure

Assembling the Rails

Assemble the right-side rail in the same way

Attaching the Rails to the Rack

6Placing the autoloader on the rails

Attaching the Autoloader to the Rails

Guidelines for Connecting to Scsi

Connecting the Autoloader to Scsi

Active Scsi terminator

Bus adapter card

See Tape Drive Operation Tape drive fails with sporadic

Including bus hangs and Read/Write failures

Wrong terminator

Making the Scsi Connections

Important Do not over-tighten the Scsi cable jack screws

8SCSI connectors on the back of the autoloader

10Connecting the autoloader to an Ethernet network

Connecting the Autoloader to Ethernet

Power cord for your location. See page 122 for power cord

Powering on the Autoloader

Requirements for other locations

Do not power on the host computer system immediately after

Verifying the Hardware Installation

On-line

1x7 Ultrium D217

Accessing Configuration Options

Configuring Autoloader

Using the Operator Panel

Viewing the Home Screen

Using the Operator Panel Buttons

LTO 1x7 2U Ultrium 3-S D217

Button Description

2Operator panel buttons

Overview of Autoloader Menus

3Autoloader menu organization

Configuration Description See Option

Setting Configuration Options

Changing the LCD Language

Option

Changing the LCD Contrast

Changing the Scsi IDS

Autoloader Scsi ID

Tape Drive Scsi ID

Emulation Mode

Changing the Emulation Mode

Computer so that it recognizes the new emulation mode

After changing the emulation mode, reboot your host

Setting UP Automatic Tape Drive Cleaning

That option OFF

Activating the Cleaning Cartridge Cell

Enabling the Autoclean Option

Setting Ethernet Configuration Options

Snmp

Setting the Ethernet Addresses

FTP Interface

Press to display the Dhcp selection screen

If you are using a backup application which is capable

Setting the Autoloader to Operate in Sequential Mode

Controlling the autoloader, do not configure the library to

Operate in Sequential mode

Press To display the operating mode selection screen

Setting UP Autoloader Password Protection

Setting Up an Operator Panel Password

Turning Off the Operator Panel Password

Accessing Password Protected Operator Panel Menus

Setting Security Through Your Application

Restoring the Default Configuration

If you enable security through your application, use

Any of the autoloader’s configuration settings are lost

Available through your application. Refer to your software

Checking the Setup

1012581

Accessing the Remote Management Utility

Using the Remote Management Utility

1Remote Management utility Status

Click this Link For quick access to this location

Library Information

Viewing Information on the Home Status

Scsi ID

LCD

Library Status

ON/OFF

Inventory

Tape Drive Status

Povar

Field Description

Label Valid

Label

Setting Configuration Options

2Remote Management utility Configuration

Change Library Configuration

Dhcp

Change Ethernet Configuration

Field Description Snmp Read

User Password

Snmp Write

Broadcast

Access It, enter the current password Password New Web

Change WEB Access Password

Viewing Information on the Statistics

Field Description Current Web

Running Diagnostics

1012581

1Location of status LED

Autoloader Operation

Inserting and Removing Cartridges

2Location of cartridge access port

Preparing Cartridges

If the switch Tape is

Ultrium 2 purple Ultrium 1 black LTO Ultrium Tape Drive

Inserting Cartridges Into the Autoloader

Insert cartridges label-side first, as shown

Write-protect switch toward you. The arrow on

Cartridge must face toward the outside

Removing Cartridges from the Autoloader

Removing Cartridges Without Power

Loading a Cartridge Into the Tape Drive

Loading and Unloading Cartridges in the Tape Drive

Unloading a Cartridge from the Tape Drive

Cleaning methods will void your warranty

Cleaning the Tape Drive

New cleaning cartridge

Cleaning the Tape Drive Using the Clean Drive Option

Cleaning process again

Cleaning the Tape Drive by Inserting a Cleaning Cartridge

Refer to your software documentation for instructions

Resetting the Autoloader

Running System Demos

Press Following screen appears

Performing Diagnostic Tests

Storing Cartridges

Viewing Basic Autoloader Information

Viewing Autoloader Information

Press . The firmware screen appears

Press . The total moves screen appears

Viewing Autoloader Sensor Readings

Press . The door open sensor screen appears

Press . The cell sensor screen appears

Viewing Basic Tape Drive Information

Viewing the Cartridge Inventory

Viewing the Cartridge Inventory and BAR Code Information

If this appears Cell

Number 1, 2 Contains a cartridge Dash Is empty

Dash Is empty

If this appears Tape drive

Updating the Cartridge Inventory

Viewing Cell Statistics

Press . The total puts screen appears

Viewing the Event LOG

Replacing the Tape Drive

Maintenance

Preparing for Replacement

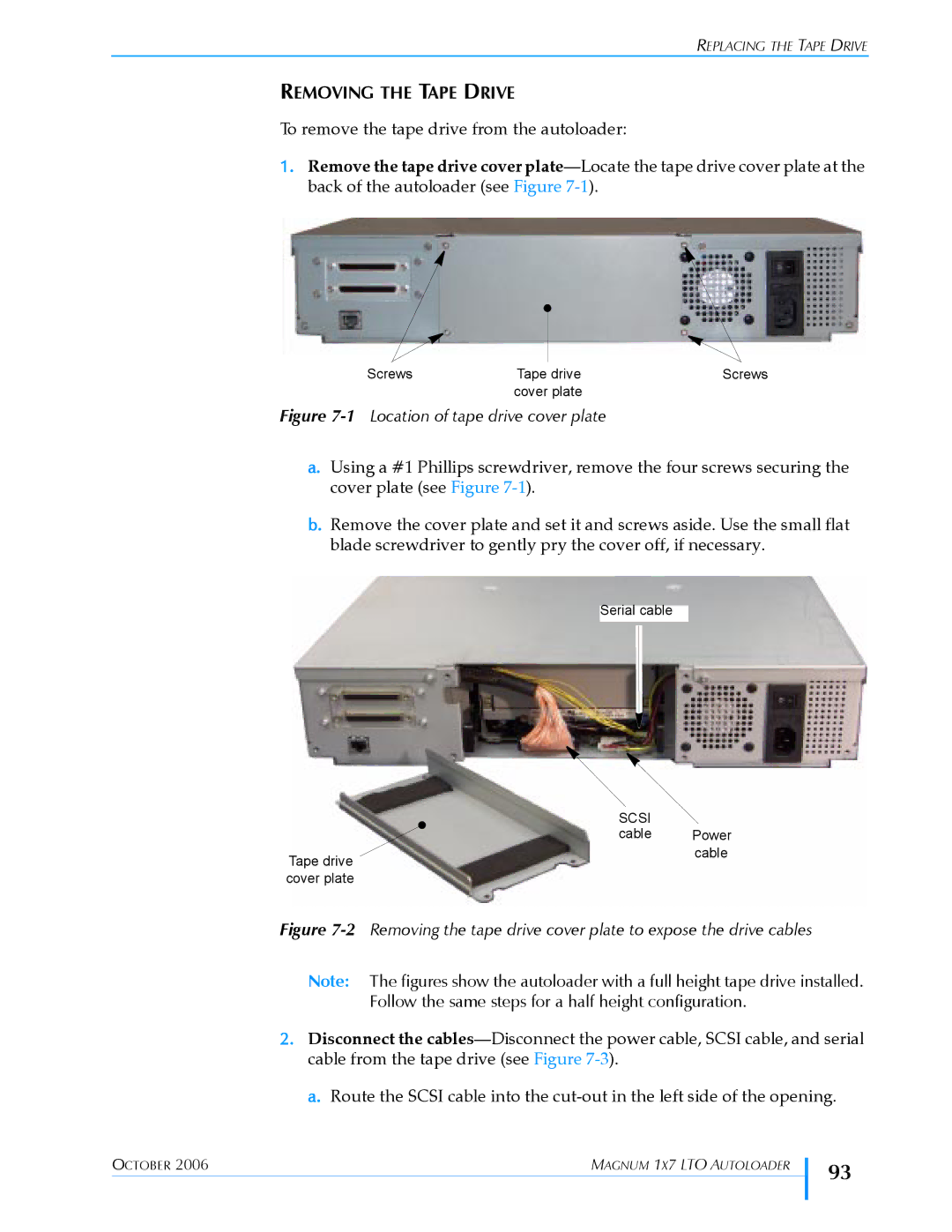

1Location of tape drive cover plate

Removing the Tape Drive

3Disconnecting the cables from the tape drive

Exabyte-approved supplier

Installing the NEW Tape Drive

7Removing the faceplate from the tape drive chassis

8Attaching the brackets to a half height tape drive

Drive with a half height tape drive, or vice versa

Full height tape drive-Install as shown

Resuming Operation

Cleaning the Autoloader

Connecting to the AUTOLOADER’S FTP Interface

FTP-AUTOLOADER Firmware Upgrade and Diagnostics

100

101

Until after it automatically resets

Upgrading Autoloader Firmware VIA FTP

Make sure that you select and download the correct firmware

102

Creating a Diagnostic Listing VIA FTP

Autoloader Troubleshooting

Troubleshooting

Autoloader Installation

103

104

Autoloader Operation

105

106

Tape Drive Fails with Sporadic Errors

Tape Drive Troubleshooting

107

Tape Drive Operation

108

Backup Software Reports AN Error

Failure to Communicate with the Tape Drive

Failure by the Tape Drive to Write or Read Data

109

Backup Software Configuration Issues

Before Contacting Technical Support

110

Autoloader and Tape Drive Information

Scsi BUS Information

Driver installation information is available at

Backup Application Information

Diagnostic Information

111

112

Advanced Troubleshooting

113

Shipping the Autoloader

Preparing the Autoloader for Shipping

114

Autoloader for service

Removing the Autoloader from the Rack

Replacing the Shipping KEY

115

Packing the Autoloader

116

5Installing the first foam packing piece

117

7Accessory kit in shipping box

Autoloader to a new location

118

Size and Weight

Specifications

Storage Capacity

Autoloader POWER-ON Sequence Time

Performance Specifications

120

Data Transfer Rate

Cartridge Inventory Times

121

Move Complete Time

Reliability

Requirements for International 220 VAC Power Cord

Power Specifications

AC Input Voltages and Power Consumption

Power Cord Specifications

General Environmental Specifications

Environmental Specifications

123

Particulate Contamination Limits

Acoustic Noise Limits

124

Shock and Vibration Limits

Operating

Safety and Regulatory Agency Compliance

Shipping Specifications

125

Underwriters Laboratory

United States FCC Declaration of Conformity

126

Canadian Verification

European Community

Japan

127

Australia and NEW Zealand

Waste of Electronic and Electrical Equipment Weee

128

129

Write ONCE, Read Many Worm Capability

Overview

130

Worm Media Errors

Tape Cartridge Case Color Native Data Capacity

Data Security on Worm Media

Requirements

131

Tapealert Flags

Parameter Code Description Set Clear Type Hex

132

Error Codes

Drive. If you do, you will void your warranty

Error Messages

Some corrective actions advise you to reset or power

Autoloader off and back on. To avoid disrupting

134

135

Error Message Description Corrective Action Drive CMD Error

136

137

Error Message Description Corrective Action Servo Timeout

138

Weee

Index

Snmp

140

103 to

141

62 to

142

16 to

143

144

145

Product Limited Warranty

146