Diagnostics and Troubleshooting

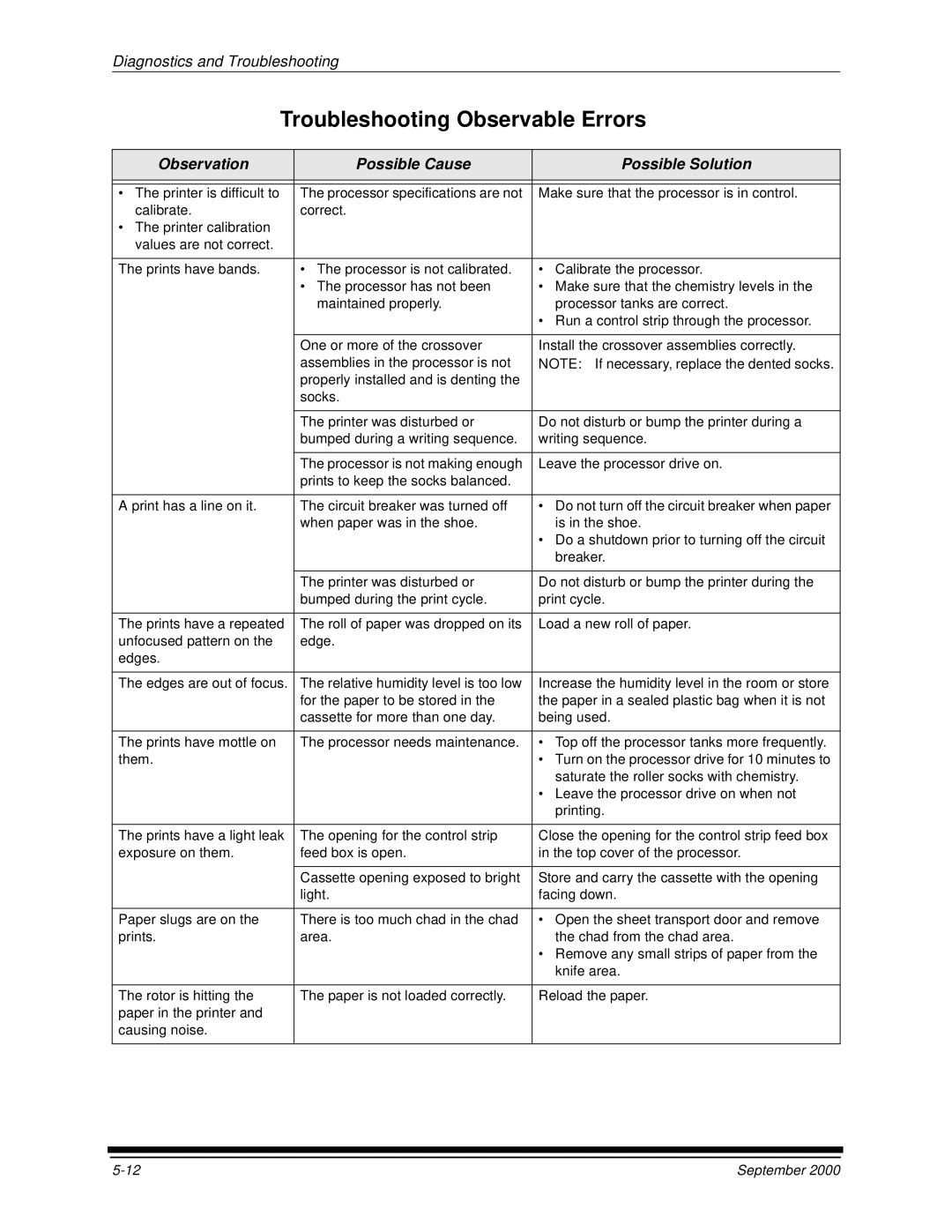

Troubleshooting Observable Errors

Observation | Possible Cause | Possible Solution |

|

|

|

|

|

|

• The printer is difficult to | The processor specifications are not | Make sure that the processor is in control. |

calibrate. | correct. |

|

• The printer calibration |

|

|

values are not correct. |

|

|

|

|

|

The prints have bands. | • The processor is not calibrated. | • Calibrate the processor. |

| • The processor has not been | • Make sure that the chemistry levels in the |

| maintained properly. | processor tanks are correct. |

|

| • Run a control strip through the processor. |

|

|

|

| One or more of the crossover | Install the crossover assemblies correctly. |

| assemblies in the processor is not | NOTE: If necessary, replace the dented socks. |

| properly installed and is denting the |

|

| socks. |

|

|

|

|

| The printer was disturbed or | Do not disturb or bump the printer during a |

| bumped during a writing sequence. | writing sequence. |

|

|

|

| The processor is not making enough | Leave the processor drive on. |

| prints to keep the socks balanced. |

|

|

|

|

A print has a line on it. | The circuit breaker was turned off | • Do not turn off the circuit breaker when paper |

| when paper was in the shoe. | is in the shoe. |

|

| • Do a shutdown prior to turning off the circuit |

|

| breaker. |

|

|

|

| The printer was disturbed or | Do not disturb or bump the printer during the |

| bumped during the print cycle. | print cycle. |

|

|

|

The prints have a repeated | The roll of paper was dropped on its | Load a new roll of paper. |

unfocused pattern on the | edge. |

|

edges. |

|

|

|

|

|

The edges are out of focus. | The relative humidity level is too low | Increase the humidity level in the room or store |

| for the paper to be stored in the | the paper in a sealed plastic bag when it is not |

| cassette for more than one day. | being used. |

|

|

|

The prints have mottle on | The processor needs maintenance. | • Top off the processor tanks more frequently. |

them. |

| • Turn on the processor drive for 10 minutes to |

|

| saturate the roller socks with chemistry. |

|

| • Leave the processor drive on when not |

|

| printing. |

|

|

|

The prints have a light leak | The opening for the control strip | Close the opening for the control strip feed box |

exposure on them. | feed box is open. | in the top cover of the processor. |

|

|

|

| Cassette opening exposed to bright | Store and carry the cassette with the opening |

| light. | facing down. |

|

|

|

Paper slugs are on the | There is too much chad in the chad | • Open the sheet transport door and remove |

prints. | area. | the chad from the chad area. |

|

| • Remove any small strips of paper from the |

|

| knife area. |

|

|

|

The rotor is hitting the | The paper is not loaded correctly. | Reload the paper. |

paper in the printer and |

|

|

causing noise. |

|

|

|

|

|

September 2000 |