101

Biases and gains of speed setting terminals

Thank you for choosing this Mitsubishi Vector Inverter

102

Electric Shock Prevention

Trial run

Transportation and installation

Wiring

Operation

Disposing of the inverter

Maintenance, inspection and parts replacement

Emergency stop

General instructions

Product check and name of parts

Abbreviations

Harmonic Suppression Guideline

Front view

Basic configuration and connection of peripheral devices

Basic configuration and connection of peripheral devices

Basic configuration

200V class

Select the NFB type according to the power supply capacity

Selection of peripheral devices

400V class

Structure

Removal and reinstallation of the front cover

Reinstallation

Structure

Structure Removal and reinstallation of the operation panel

Reinstallation using the connection cable

Reinstallation

Installation of the inverter

Installation of the inverter

Install the inverter under the following conditions

Connection diagram, PLG cable, PU connector

Connection diagram, PLG cable, PU connector

Connection diagram

Connection diagram, PLG cable, PU connector Main circuit

Specification of main circuit terminal

Terminal Symbol Terminal Name Description

Terminal arrangement of the main circuit terminal

Screw size M8

400V class

Screw size M6

400V class When input power supply is

Cables and wiring length

200V class When input power supply is

Cable gause for the control circuit power

Setting the PLG

PLG output circuit jumper connector

Type Length L m

Parameter Name Factory Setting Setting Range Remarks

Pr Setting Relationship between the motor and PLG

Connection diagram, PLG cable, PU connector Control circuit

Specifications of control circuit terminals

Type Terminal Terminal Name Description Symbol

Wiring instructions

Not output during inverter reset

Control circuit terminal layout

Changing the control logic

When using an external power supply for transistor output

For computer link communication

Parameter Name Factory Setting Setting Range

Setting the m otor

Setting the motor

Dedicated motor SF-V5R 1500r/min series

At-a-glance guide to motor setting

When using other manufacturers’ motors

Precautions for use of the vector inverter

Precautions for use of the vector inverter

Motor Rated Voltage

Checks prior to test run

Basic operation Speed setting, run, speed meter adjustment

Setting the speed and running the motor

Checks prior to test run

PU jog operation

Basic operation Speed setting, run, speed meter adjustment

Turn on the start switch STF or STR

Operation status indication FWD or REV flickers

External jog operation

It may take some time until the pointer moves

Changing example

Display the present operation speed by pressing SET to

To stop the inverter

Key indication

Names and functions of the operation panel

Names and functions of the opera- tion panel

Unit indication, operation status indication

Alarm *1 absent

Speed setting

Used to set the running speed in the PU operation mode

Monitoring

Operation mode

Once, press SET , and restart the setting from the beginning

Names and functions of the opera- tion panel Help mode

Alarm history

Alarm history clear Clears all alarm history

Parameter clear

All clear

Names and functions of the opera- tion panel Copy mode

Parameter setting mode

Speed control operation

Setting procedure

Speed control operation

Speed control

Speed command

Speed control operation Operation command setting

Forward and reverse rotation commands terminals STF, STR

Torque restriction

Torque restriction level

Second torque restriction level

Torque restrictions during acceleration and deceleration

Gain adjustment

Preset speed-speed

Pr deceleration torque

Torque control operation

When 0 is set in Pr or Pr acceleration/deceleration time

Torque control operation

Torque control

Signal Terminal Name Remarks

O signals

Following table indicates the operations of the signals

Operation example Pr =0

Torque command setting

Torque control operation Setting procedure

Torque command right selection

Perform secure wiring. Refer to Set the PLG. Refer to

Speed restriction

When Pr =

Used to give a speed restriction command

10E +10V

Position control operation

Position command from parameter setting

Position command from PLC

Position control operation

〈 Example Speed Position, when Pr = 4〉

Control mode switchover timing

Control mode switchover timing

Assumes that the Pr value is the factory setting

Easy gain tuning execution procedure

Easy gain tuning

Easy gain tuning

Start signal

Checking the Pr control system selection value

Easy gain tuning Precautions for easy gain tuning

Automatically set parameters by easy gain tuning

Load inertia estimation restriction conditions

Page

2 Pr =1 start-time tuning

Online auto tuning

Online auto tuning

3 Pr = 2 normal tuning/adaptive magnetic flux observer

Torque %

Setting

Output speed

10V

Setting change 1.5 s

Read Pr to display the currently set gain speed

Current analog voltage adjustment value

Example When the analog

Value is 100%

Function list Simple mode parameters

Function list Simple mode parameters

Simple mode parameter list

Refer to page 62 for Pr soft PW M control

Setting Carrier Frequency

You can change the motor sound

Pr maximum speed, Pr minimum speed

Refer to page 46 for details

Pr extended function display selection

Setting Drive System Control Method Remarks

Refer to page 43 for details

Pr control system selection

Function list Extended function parameters

Function list Extended function parameters

Speed jump 1A

Deceleration pattern

Regenerative

Speed jump 1B

Alarm occurrence

Remote setting

Intelligent mode

DA1 terminal function

Speed setting signal

Applied motor

PWM frequency Selection

Operation mode

Reset selection

Parameter write Disable selection Reverse rotation

Online auto tuning Selection Auto tuning setting

Switchover

123 Waiting time setting

144 Speed setting

117 Station number

Power failure

157 OL signal output

Timer

Stall prevention 156 Operation selection

171 Actual operation hour

Maker setting parameters. Do not make setting 169

168

Meter clear DI1 terminal function

234 Multi-speed setting

232 Multi-speed setting

Multi-speed setting 233

236 Multi-speed setting

Command 357 In-position zone

Command selection

Switchover speed

286 Droop gain

Command filter

Position command

Command pulse 420 Scaling factor Numerator

427 Excessive level error

465 First position feed

Digital position

464 Control sudden stop

Amount lower 4 digits

805 Torque command

Selection 801 Torque characteristic

Characteristic

Value RAM Torque command

826 Torque setting filter

818 Easy gain tuning Response level setting 819

822 Speed setting filter

832 Speed setting filter

841 Torque bias

Adjustment

840 Torque bias selection

842 Torque bias

890 Maintenance output

874 OLT level setting

Fault definition

Setting time 892 Maintenance output

Errors Alarms

Errors Alarms

Major faults

Motor Overload

OV During Acc

OV During Dec

Inv. Overload

Inst. Pwr. Loss

Br. Cct. Fault

Ground Fault

Under Voltage

Option slot alarm 1 to

OH Fault

Option Fault

Stll Prev STP OL shown during stall

Corrupt Memry

Fault 1 to Fault

CPU Fault

PU Leave Out

Operation Panel P24

Fault

Indication Fault Name

Operation Panel P12

No encoder a signal

No encoder signal

Excessive position error

Overspeed occurrence

Minor fault

Fan Failure

Stall prevention

Operation Panel Err Indication

Errors Alarms How to recover from PU stop error PS

Reset from operation panel

Resetting the inverter

Correspondences between digital and actual characters

Correspondences between digital and actual characters

Memo

Motor generates abnormal noise

Troubleshooting

Troubleshooting

Vector control

Troubleshooting Motor does not rotate

Vector control

For speed restriction?

Command been

Is the torque

Parameter

F control

Troubleshooting Motor generates heat abnormally

Troubleshooting Motor hunts

Speed control

Being made?

Troubleshooting Machine operates unstably

Troubleshooting Speed command does not match motor speed

Have you set the motor type? Is the PLG setting correct?

Does the inverters speed command match the motor speed?

Troubleshooting Motor rotates but speed does not change

Torque control

Troubleshooting Torque control is not exercised normally

Is the wiring length short?

Pr , Pr Is an external

Frequency low?

Is the torque command unvaried?

Reduce noise

Filter Pr

Insulation resistance test using megger

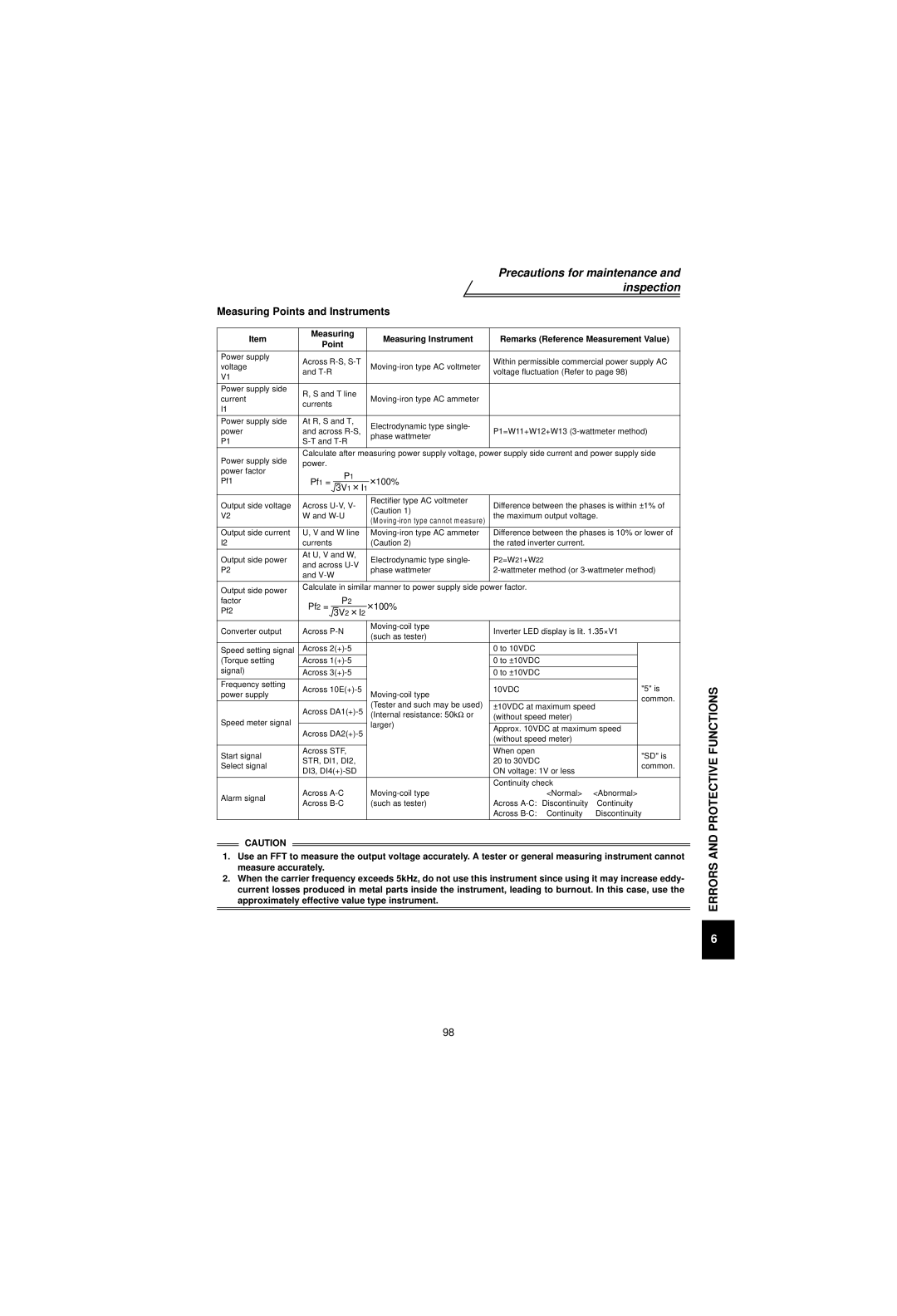

Precautions for maintenance and inspection

Precautions for maintenance and inspection

Check items

Precautions for maintenance and inspection Pressure test

Daily and periodic inspection

Do not conduct a pressure test. Deterioration may occur

Interval

Replacement of parts

Part Name Standard Replacement Interval Description

Area Inspection Description

Cooling fan

Smoothing capacitors

Relays

Measurement of main circuit voltages, currents and powers

Examples of Measuring Points and Instruments

100%

Measuring Points and Instruments

100% Pf1 =

Pf2 =

Model specifications

Model specifications

10.0 12.8 19.0 24.6 30.4 35.8 46.3 59.5 68.5 91.0

Three-phase, 380 to 480V 50Hz/60Hz

Three-phase, 380V to 480V 50Hz/60Hz

10.0 14.5 18.5 27.5 35.5 51.8 132

Common specifications

Common specifications

Inverter outline dimension drawings

Outline dimension drawings

Outline dimension drawings

FR-V520-1.5K‚ 2.2K FR-V540-1.5K‚ 2.2K

FR-V520-11K‚ 15K FR-V540-7.5K‚ 11K, 15K, 18.5K

FR-V520-18.5K

250

FR-V520-22K, 30K‚ 37K !FR-V540-22K, 30K‚ 37K

Inverter Type

SF-V5RH 1K

SF-V5RH 2K ‚ 3K

SF-V5RH 5K ‚ 7K

SF-V5RH 30K ‚ 37K ‚ 45K ‚ 55K

110

For Maximum Safety

Print Date Manual Number Revision