Chapter 1 Unpacking The Printer

Bar Code Verification

The most important consideration when printing a bar code is to ensure the bar code will be scanned properly. Incorporating a bar code quality procedure in the printing process is the best way to ensure that bar codes are being printed correctly. A properly implemented verification procedure will increase overall bar code quality, reduce waste from misprinted bar codes, and achieve high first time read rates, which is an increasingly important factor in newer, more efficient systems, where manually entered data is not acceptable as a back up function. Verification also minimizes the costs of returned products due to poor reading or unaccountable bar codes.

RJS designs and manufactures the world’s most complete line of bar code verification products, including their portable Inspector and Laser Inspector models,

Unpacking The Printer

The printer is shipped in a carton and protective bag. Keep all packing material in case you need to move or ship the printer again. Avoid touching the electrical connectors to prevent electrostatic discharge damage while setting up the printer.

CAUTION The discharge of electrostatic energy that accumulates on the surface of the human body or other surfaces can damage or destroy the print head or electronic components used in this device.

CAUTION Damage to the printer interface connector may result from placing the T4204 printer on its backside during unpacking or handling.

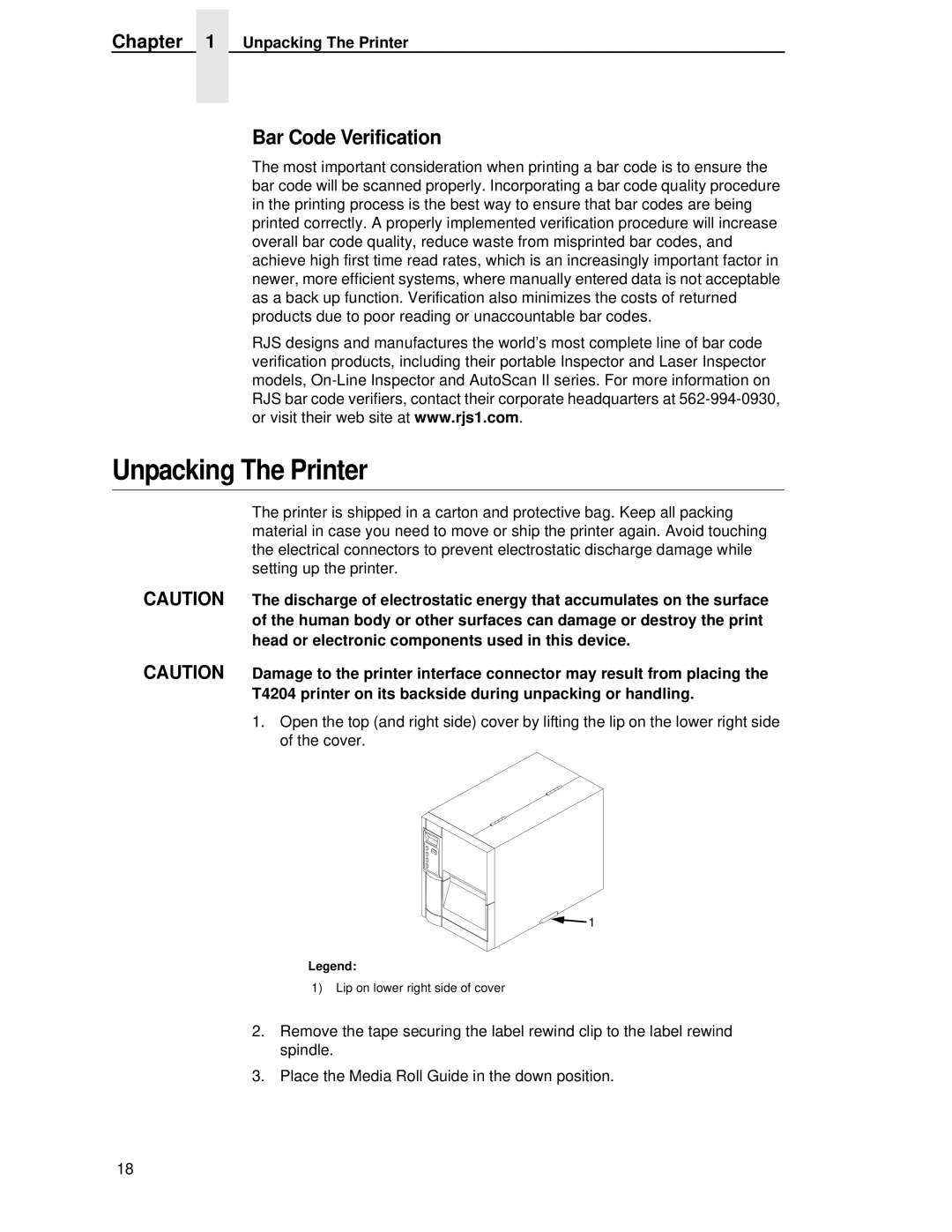

1.Open the top (and right side) cover by lifting the lip on the lower right side of the cover.

![]()

![]() 1

1

Legend:

1)Lip on lower right side of cover

2.Remove the tape securing the label rewind clip to the label rewind spindle.

3.Place the Media Roll Guide in the down position.

18