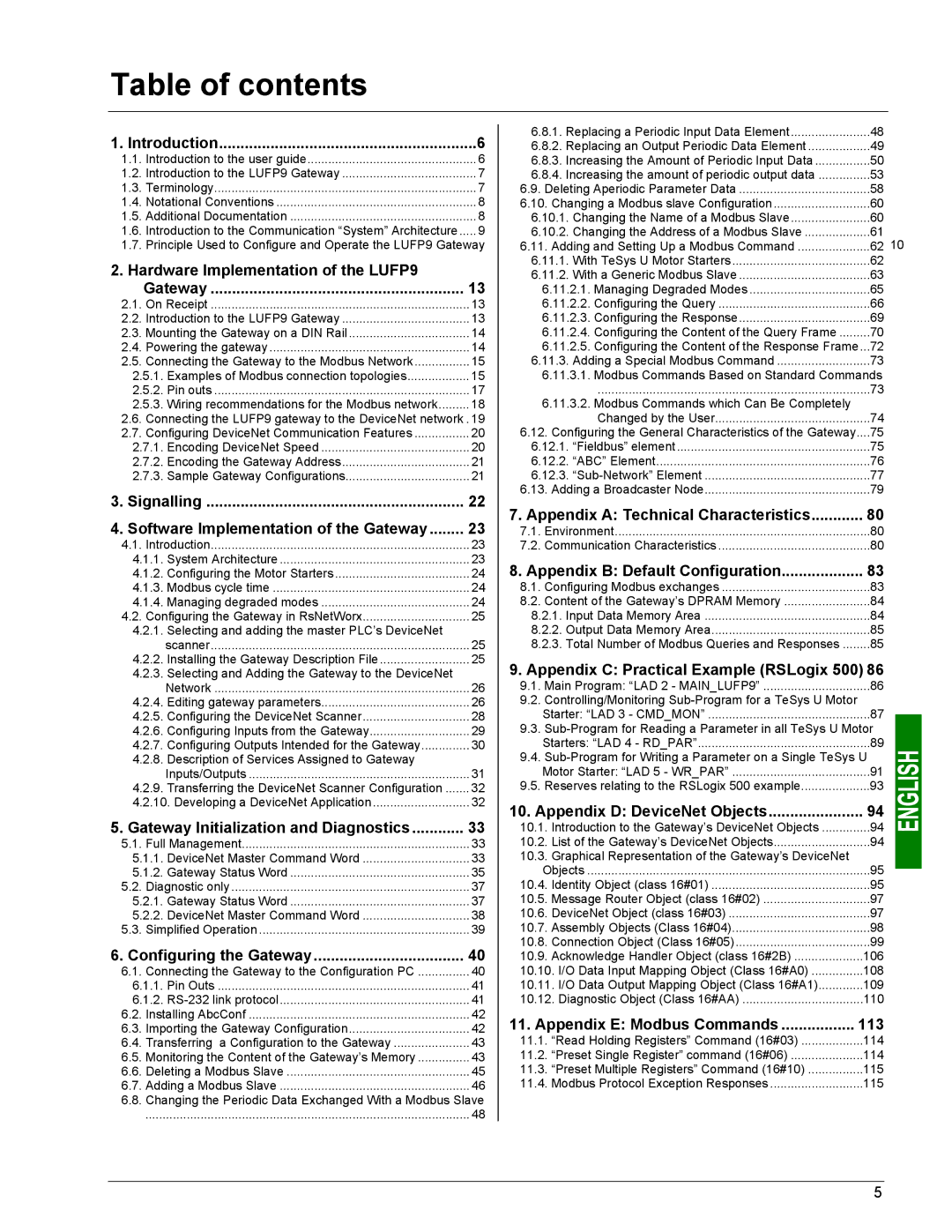

Table of contents

1. Introduction | 6 |

1.1. Introduction to the user guide | 6 |

1.2. Introduction to the LUFP9 Gateway | 7 |

1.3. Terminology | 7 |

1.4. Notational Conventions | 8 |

1.5. Additional Documentation | 8 |

1.6. Introduction to the Communication “System” Architecture | 9 |

1.7.Principle Used to Configure and Operate the LUFP9 Gateway

2.Hardware Implementation of the LUFP9

Gateway | 13 |

2.1. On Receipt | 13 |

2.2. Introduction to the LUFP9 Gateway | 13 |

2.3. Mounting the Gateway on a DIN Rail | 14 |

2.4. Powering the gateway | 14 |

2.5. Connecting the Gateway to the Modbus Network | 15 |

2.5.1. Examples of Modbus connection topologies | 15 |

2.5.2. Pin outs | 17 |

2.5.3. Wiring recommendations for the Modbus network | 18 |

2.6. Connecting the LUFP9 gateway to the DeviceNet network . 19 | |

2.7. Configuring DeviceNet Communication Features | 20 |

2.7.1. Encoding DeviceNet Speed | 20 |

2.7.2. Encoding the Gateway Address | 21 |

2.7.3. Sample Gateway Configurations | 21 |

3. Signalling | 22 |

4. Software Implementation of the Gateway | 23 |

4.1. Introduction | 23 |

4.1.1. System Architecture | 23 |

4.1.2. Configuring the Motor Starters | 24 |

4.1.3. Modbus cycle time | 24 |

4.1.4. Managing degraded modes | 24 |

4.2. Configuring the Gateway in RsNetWorx | 25 |

4.2.1. Selecting and adding the master PLC’s DeviceNet |

|

scanner | 25 |

4.2.2. Installing the Gateway Description File | 25 |

4.2.3. Selecting and Adding the Gateway to the DeviceNet |

|

Network | 26 |

4.2.4. Editing gateway parameters | 26 |

4.2.5. Configuring the DeviceNet Scanner | 28 |

4.2.6. Configuring Inputs from the Gateway | 29 |

4.2.7. Configuring Outputs Intended for the Gateway | 30 |

4.2.8. Description of Services Assigned to Gateway |

|

Inputs/Outputs | 31 |

4.2.9. Transferring the DeviceNet Scanner Configuration | 32 |

4.2.10. Developing a DeviceNet Application | 32 |

5. Gateway Initialization and Diagnostics | 33 |

5.1. Full Management | 33 |

5.1.1. DeviceNet Master Command Word | 33 |

5.1.2. Gateway Status Word | 35 |

5.2. Diagnostic only | 37 |

5.2.1. Gateway Status Word | 37 |

5.2.2. DeviceNet Master Command Word | 38 |

5.3. Simplified Operation | 39 |

6. Configuring the Gateway | 40 |

6.1. Connecting the Gateway to the Configuration PC | 40 |

6.1.1. Pin Outs | 41 |

6.1.2. | 41 |

6.2. Installing AbcConf | 42 |

6.3. Importing the Gateway Configuration | 42 |

6.4. Transferring a Configuration to the Gateway | 43 |

6.5. Monitoring the Content of the Gateway’s Memory | 43 |

6.6. Deleting a Modbus Slave | 45 |

6.7. Adding a Modbus Slave | 46 |

6.8.Changing the Periodic Data Exchanged With a Modbus Slave

.............................................................................................. 48

6.8.1. Replacing a Periodic Input Data Element | 48 |

|

6.8.2. Replacing an Output Periodic Data Element | 49 |

|

6.8.3. Increasing the Amount of Periodic Input Data | 50 |

|

6.8.4. Increasing the amount of periodic output data | 53 |

|

6.9. Deleting Aperiodic Parameter Data | 58 |

|

6.10. Changing a Modbus slave Configuration | 60 |

|

6.10.1. Changing the Name of a Modbus Slave | 60 |

|

6.10.2. Changing the Address of a Modbus Slave | 61 | 10 |

6.11. Adding and Setting Up a Modbus Command | 62 | |

6.11.1. With TeSys U Motor Starters | 62 |

|

6.11.2. With a Generic Modbus Slave | 63 |

|

6.11.2.1. Managing Degraded Modes | 65 |

|

6.11.2.2. Configuring the Query | 66 |

|

6.11.2.3. Configuring the Response | 69 |

|

6.11.2.4. Configuring the Content of the Query Frame | 70 |

|

6.11.2.5. Configuring the Content of the Response Frame... | 72 |

|

6.11.3. Adding a Special Modbus Command | 73 |

|

6.11.3.1.Modbus Commands Based on Standard Commands

...............................................................................73

6.11.3.2.Modbus Commands which Can Be Completely

Changed by the User | 74 |

6.12. Configuring the General Characteristics of the Gateway.... | 75 |

6.12.1. “Fieldbus” element | 75 |

6.12.2. “ABC” Element | 76 |

6.12.3. | 77 |

6.13. Adding a Broadcaster Node | 79 |

7. Appendix A: Technical Characteristics | 80 |

7.1. Environment | 80 |

7.2. Communication Characteristics | 80 |

8. Appendix B: Default Configuration | 83 |

8.1. Configuring Modbus exchanges | 83 |

8.2. Content of the Gateway’s DPRAM Memory | 84 |

8.2.1. Input Data Memory Area | 84 |

8.2.2. Output Data Memory Area | 85 |

8.2.3. Total Number of Modbus Queries and Responses | 85 |

9. Appendix C: Practical Example (RSLogix 500) 86 | |

9.1. Main Program: “LAD 2 - MAIN_LUFP9” | 86 |

9.2. Controlling/Monitoring |

|

Starter: “LAD 3 - CMD_MON” | 87 |

9.3. | |

Starters: “LAD 4 - RD_PAR” | 89 |

9.4. | |

Motor Starter: “LAD 5 - WR_PAR” | 91 |

9.5. Reserves relating to the RSLogix 500 example | 93 |

10. Appendix D: DeviceNet Objects | 94 |

10.1. Introduction to the Gateway’s DeviceNet Objects | 94 |

10.2. List of the Gateway’s DeviceNet Objects | 94 |

10.3. Graphical Representation of the Gateway’s DeviceNet |

|

Objects | 95 |

10.4. Identity Object (class 16#01) | 95 |

10.5. Message Router Object (class 16#02) | 97 |

10.6. DeviceNet Object (class 16#03) | 97 |

10.7. Assembly Objects (Class 16#04) | 98 |

10.8. Connection Object (Class 16#05) | 99 |

10.9. Acknowledge Handler Object (class 16#2B) | 106 |

10.10. I/O Data Input Mapping Object (Class 16#A0) | 108 |

10.11. I/O Data Output Mapping Object (Class 16#A1) | 109 |

10.12. Diagnostic Object (Class 16#AA) | 110 |

11. Appendix E: Modbus Commands | 113 |

11.1. “Read Holding Registers” Command (16#03) | 114 |

11.2. “Preset Single Register” command (16#06) | 114 |

11.3. “Preset Multiple Registers” Command (16#10) | 115 |

11.4. Modbus Protocol Exception Responses | 115 |

5